Parameter Configuration Method of Cable Arranging Guide Rod Pair of Double Twist Machine

A parameter configuration method and double-twisting machine technology, which are applied to auxiliary devices for rope making, textiles, papermaking, textile cables, etc., can solve the problems of insufficient fixed length of take-up, unreasonable design, and expansion, and achieve flexible relative movement. , Guarantee the effect of improving the bearing capacity and pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] The implementation of the present invention will be described in detail below in conjunction with the examples of implementation, but they do not constitute a limitation of the present invention, and are only examples. At the same time, the advantages of the present invention will become clearer and easier to understand.

[0070] A method for configuring the parameters of a twin-twisting machine cable guide rod pair according to the present invention comprises the following steps:

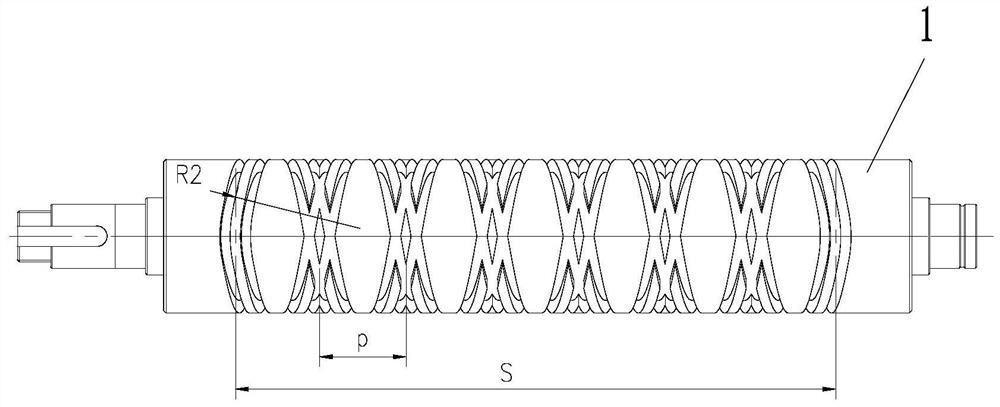

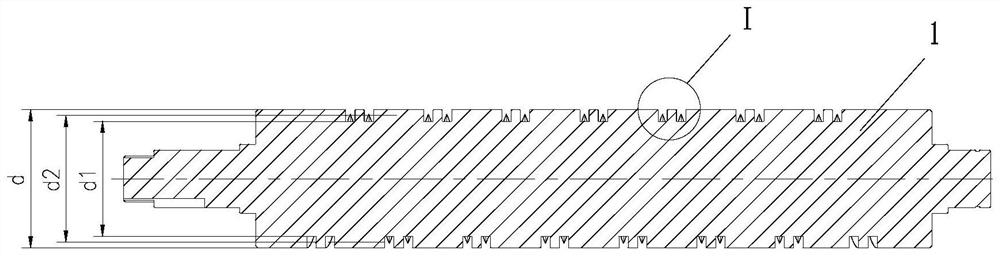

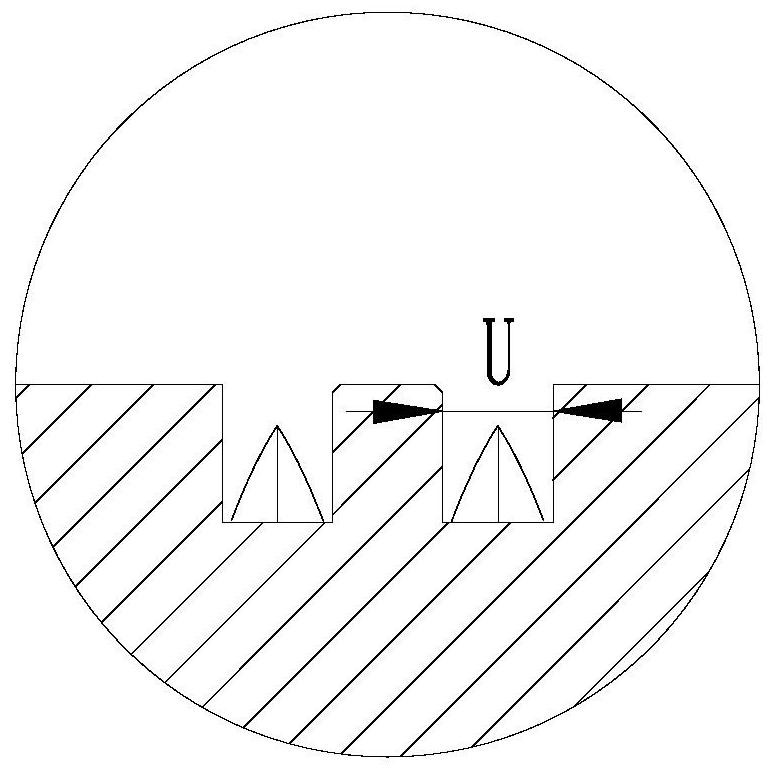

[0071] 1) According to the diameter d of the winding wire, select the guide rod and its supporting guide; when the diameter d≥1mm of the winding wire, select the two-way double-slot guide rod 1 (such as Figure 1~3 shown) and two-way double groove guide 2 (such as Figure 4~6 shown), and choose the bidirectional double groove guide rod 1 to adopt rectangular thread; when the diameter of the winding wire d Figure 7 shown) and bidirectional single groove guide 4 (such as Figure 8-9 Shown), ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com