A Reliability Test Method for Instrument Electric Control System

An electronic control system and reliability technology, which is applied in the direction of environment/reliability testing, instrumentation, measuring electricity, etc., can solve the problem of missing the best time for product reliability improvement, unfavorable instrument electronic control system fault location, long test time, etc. problems, to achieve the effect of shortening the reliability test cycle, accurate reliability test results, and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

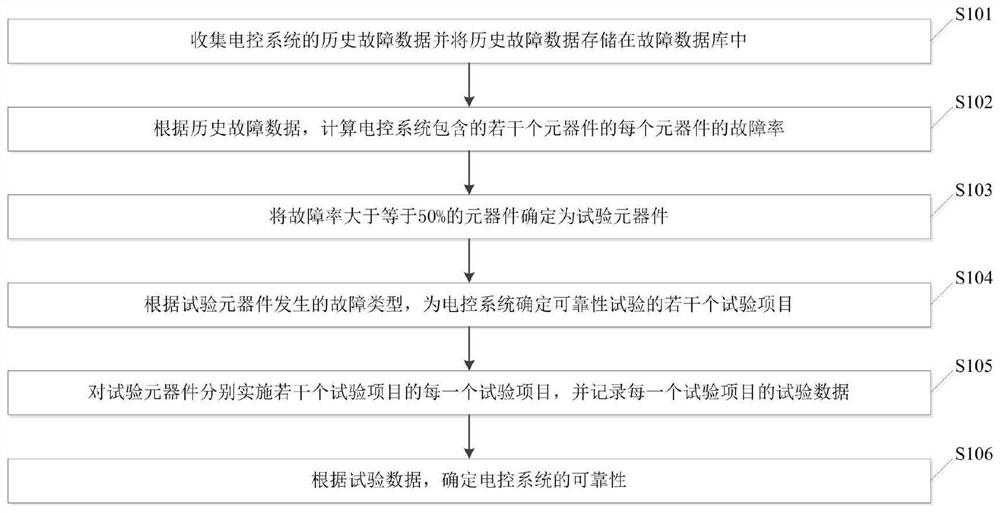

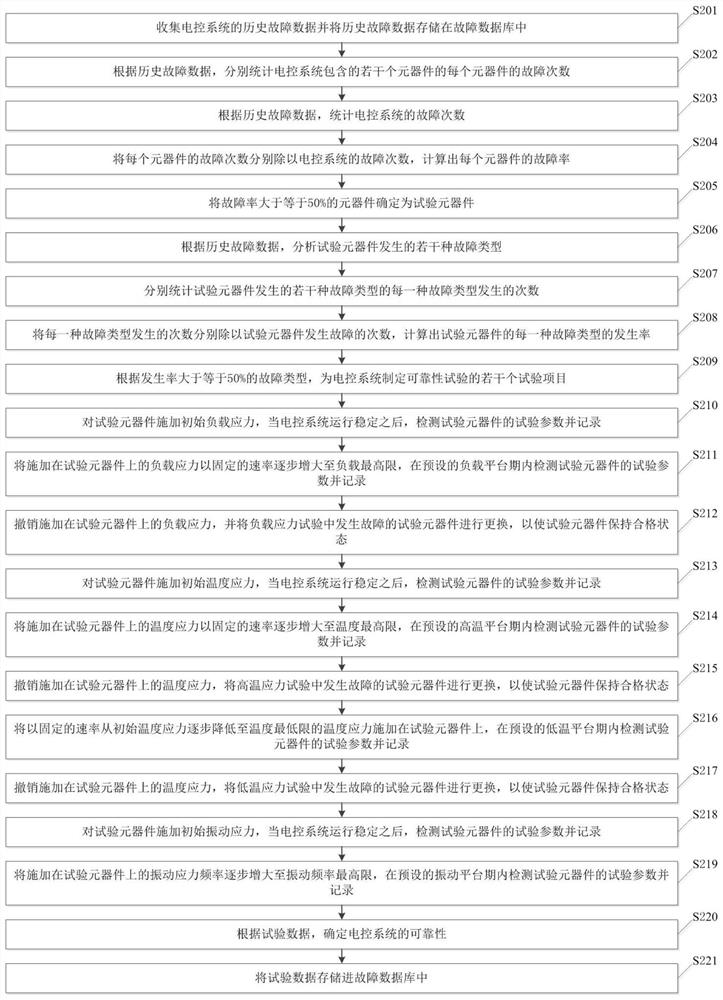

[0055] This embodiment provides another reliability test method for the electronic control system of the instrument, such as figure 2 as shown, figure 2 It is a flow chart of another reliability test method for an electronic control system of an instrument according to Embodiment 1 of the present invention, including the following steps:

[0056] Step S201: collecting historical fault data of the electronic control system and storing the historical fault data in a fault database;

[0057] In the embodiment of the present invention, the historical fault data includes the name of the faulty component, the fault type and the cause of the fault of the faulty component;

[0058] Step S202: According to the historical fault data, respectively count the number of faults of each component of several components included in the electronic control system;

[0059] Step S203: According to the historical failure data, the number of failures of the electronic control system is counted; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com