Detection method based on special robot end effector performance comprehensive test system

An end effector and comprehensive testing technology, applied in the field of robot testing, can solve the problems of low reliability, long time, low test efficiency, etc., and achieve the effect of coherent and stable movements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings.

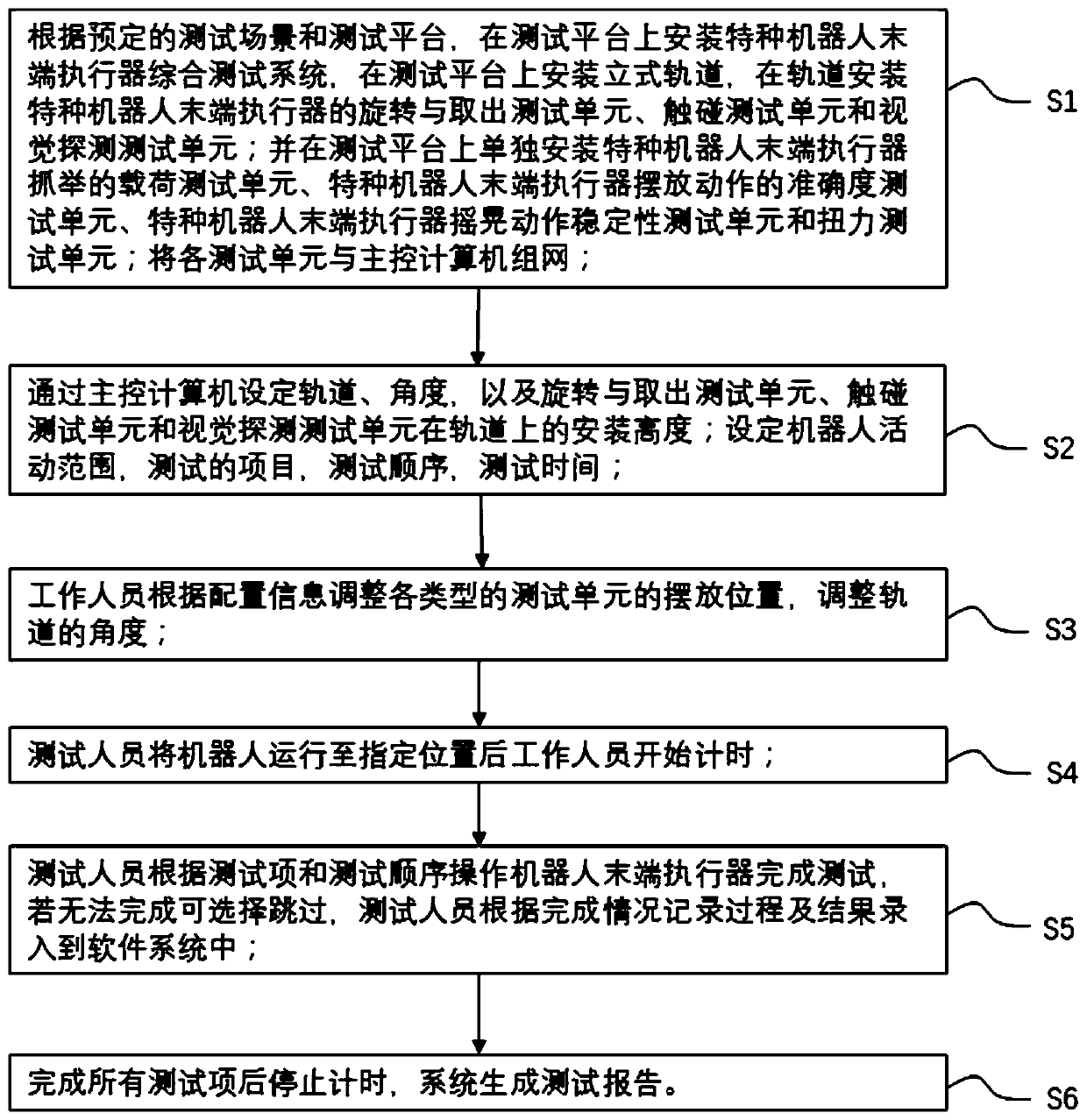

[0038] see Figure 1 to Figure 16 , the present invention provides a detection method based on a special robot end effector performance comprehensive test system, which is detected according to the following method:

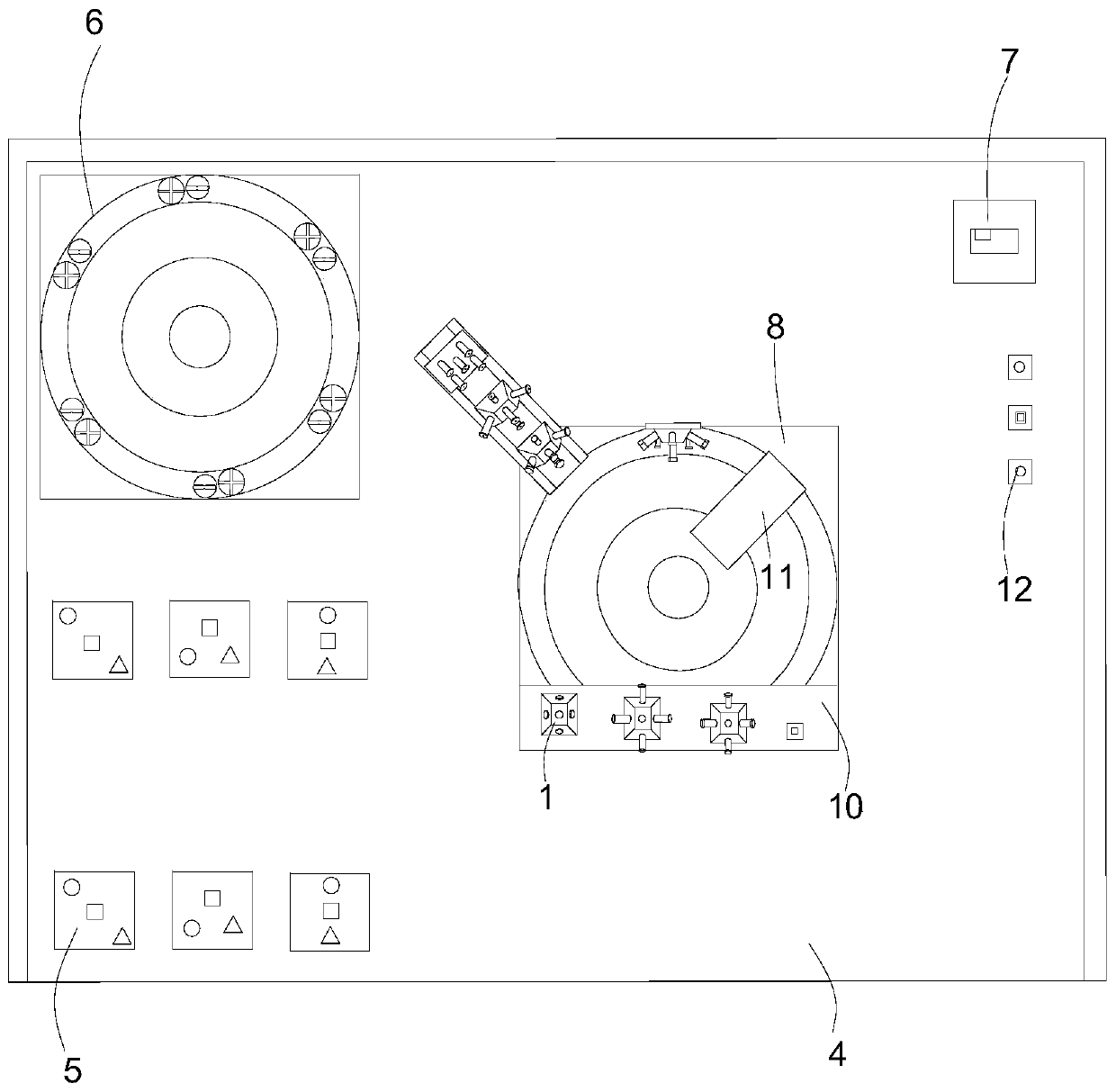

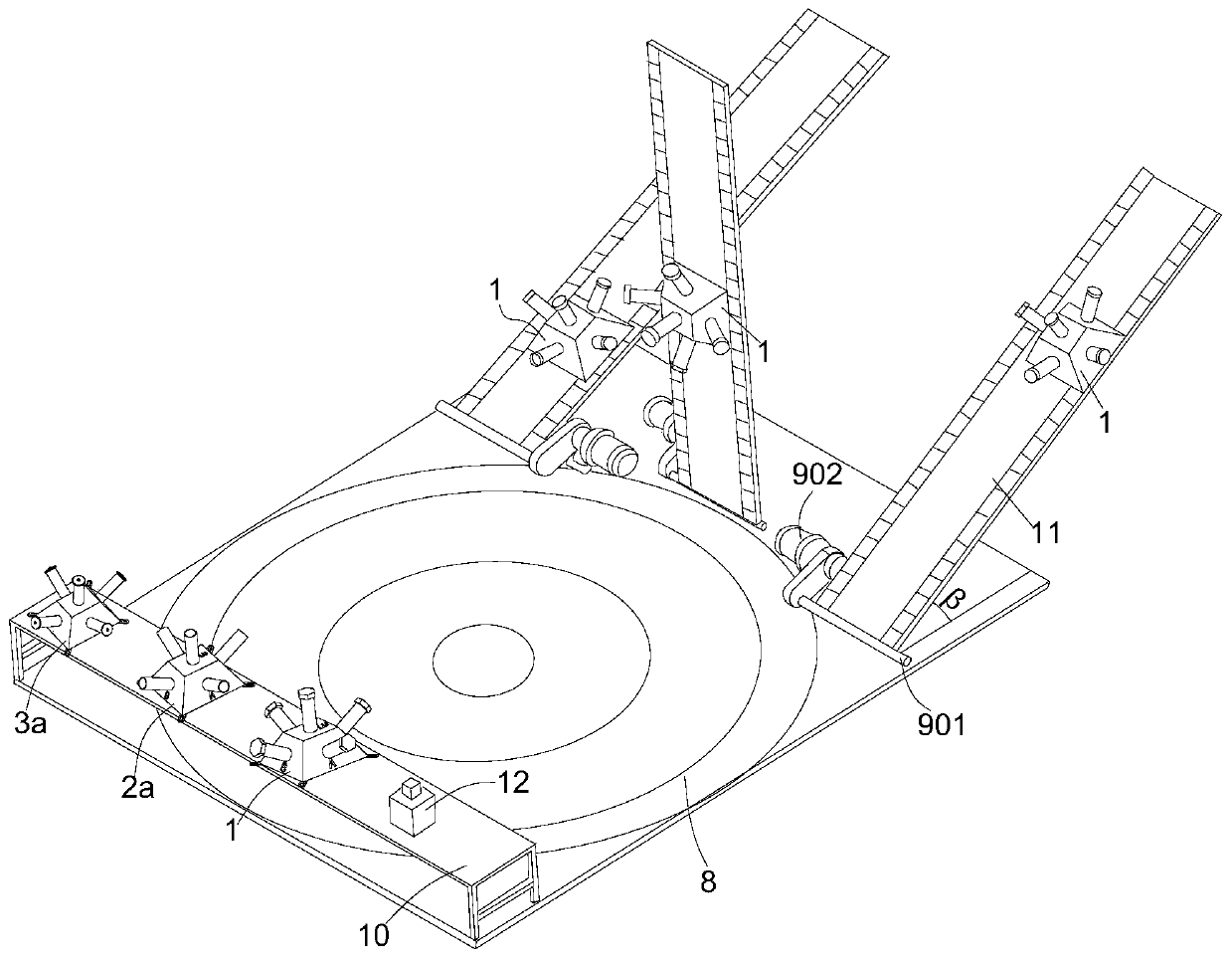

[0039] Step S1, according to the predetermined test scene and test platform, install the special robot end effector comprehensive test system on the test platform, install the vertical track on the test platform, install the rotation and removal test unit of the special robot end effector on the track, The touch test unit and the visual detection test unit; and the load test unit for the grabbing of the end effector of the special robot, the accuracy test unit for the placement of the end effector of the special robot, and the stability of the shaking movement of the end effector of the special robot are separately installed on the test platform. Sex tes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com