Automatic tarpaulin covering device used for vehicle tank and application method

A technology of tarpaulin and carriage, which is applied in the field of automatic cover tarpaulin device of carriage, which can solve the problems of loss of scattered objects, lax covering, environmental pollution, etc., and achieve the effect of meeting work needs and smooth and stable movement of the mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

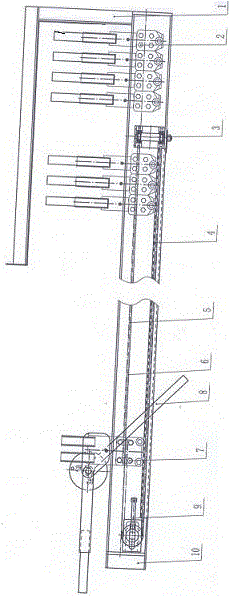

[0030]Embodiment 1. The present invention is composed of a remote controller, an intelligent controller, a motor, a double output shaft reducer, a reducer bracket, a tarpaulin protective cover 1, a single bearing pulley assembly 2, a wire rope support assembly 3, and a tarpaulin deployment wire rope 4, Tarpaulin retraction wire rope 5, thick wire rope track 6, double bearing pulley assembly 7, tail U-shaped frame automatic reset device 8, wire rope tightening device 9, guide rail support frame 10, tarpaulin U-shaped frame 11, wire rope pulley block assembly 12 The motor and the double output shaft reducer are installed together by bolts, while the reducer is installed on the reducer bracket, the reducer bracket is installed on the wire rope pulley block assembly 12, and fixed by bolts, the wire rope pulley block assembly 12 is welded on On the front part 13 of the car box body, and the wire rope support assembly 3 is also welded on the front part 13 of the car box body; one end...

Embodiment 2

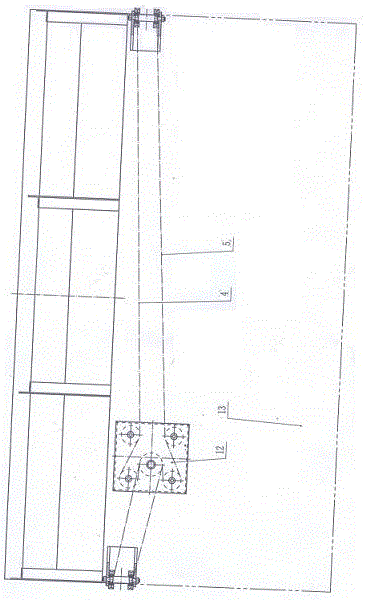

[0031] Embodiment 2, the described wire rope pulley block assembly 12, it is made of lower fixed plate 14, bearing 15, first positioning sleeve 16, first pin shaft 17, first pulley 18, second pulley 19, second pin shaft 20 , the second positioning sleeve 21, the upper cover plate 22, the third pin shaft 23, and the third positioning sleeve 24, the first pin shaft 17, the second pin shaft 20, and the third pin shaft 23 are respectively welded on the lower fixing plate 14, The second positioning sleeve 21 is installed on the second pin shaft 20; the first pulley 18 with the bearing 15, the second pulley 19 with the flat key, and the pulley with the bearing are respectively installed on the first pin shaft 17 and the second pin shaft 17. Pin 20, the third pin 23, then the first positioning sleeve 16, the second positioning sleeve 21, the third positioning sleeve 24 are respectively installed on the first pin 17, the second pin 20, the third pin 23 On, compress the inner ring of t...

Embodiment 3

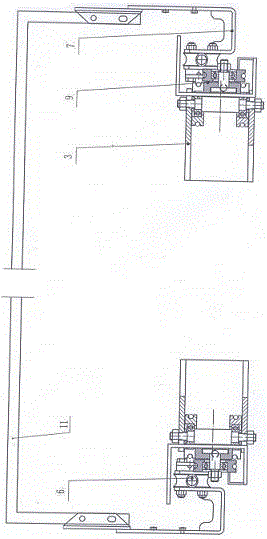

[0032] Embodiment 3, the described steel wire rope support assembly 3, it is made up of pin shaft fixing frame 25, nut 26, support positioning sleeve 27, support pulley 28, support pin 29, support bearing 30, and support bearing 30 is installed on support pulley 28, the support pulley 28 that support bearing 30 is housed is installed on support pin shaft 29 two ends respectively, and support positioning sleeve 27 is installed at both ends, then the whole is installed on the pin shaft fixed frame 25, and both sides pass through Nut 26 is tightened and fixed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com