Flat mop cleaning equipment with transmission mechanism and use method of flat mop cleaning equipment

A technology of cleaning equipment and transmission mechanism, which is applied in cleaning equipment, application, carpet cleaning, etc. It can solve the problems of small hand strength, laborious cleaning of mop buckets, complicated pipeline connection methods, etc., and achieve stable connection and brief pipeline connection methods. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

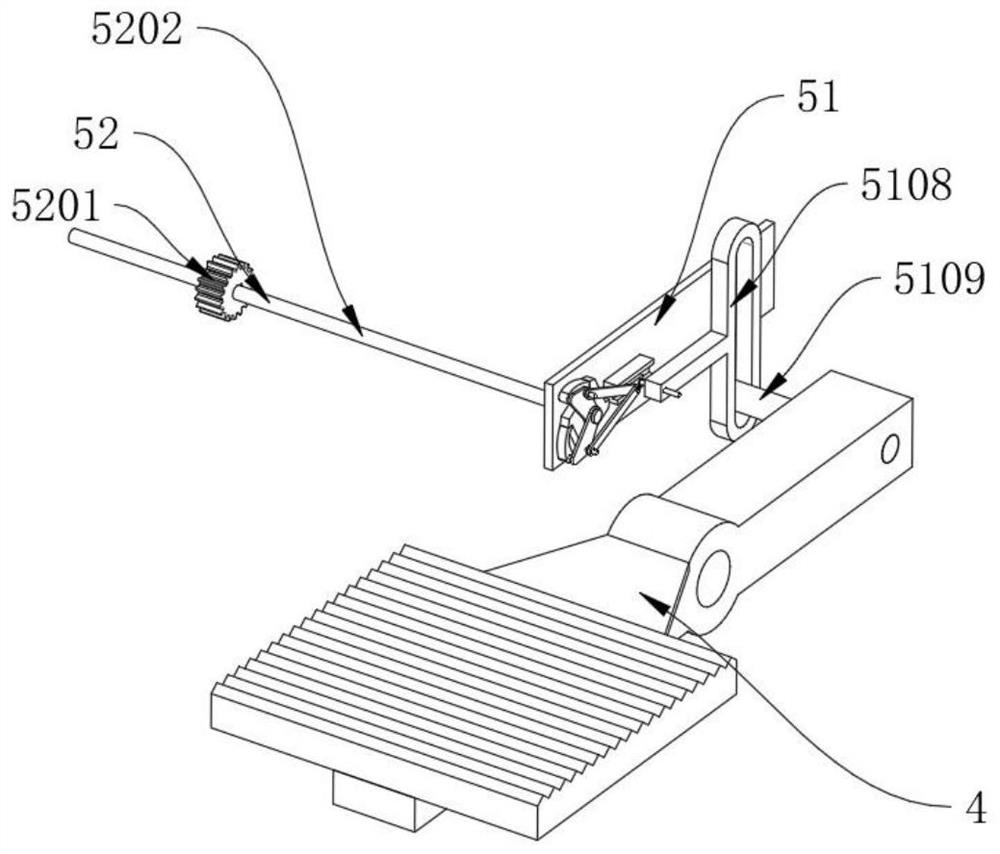

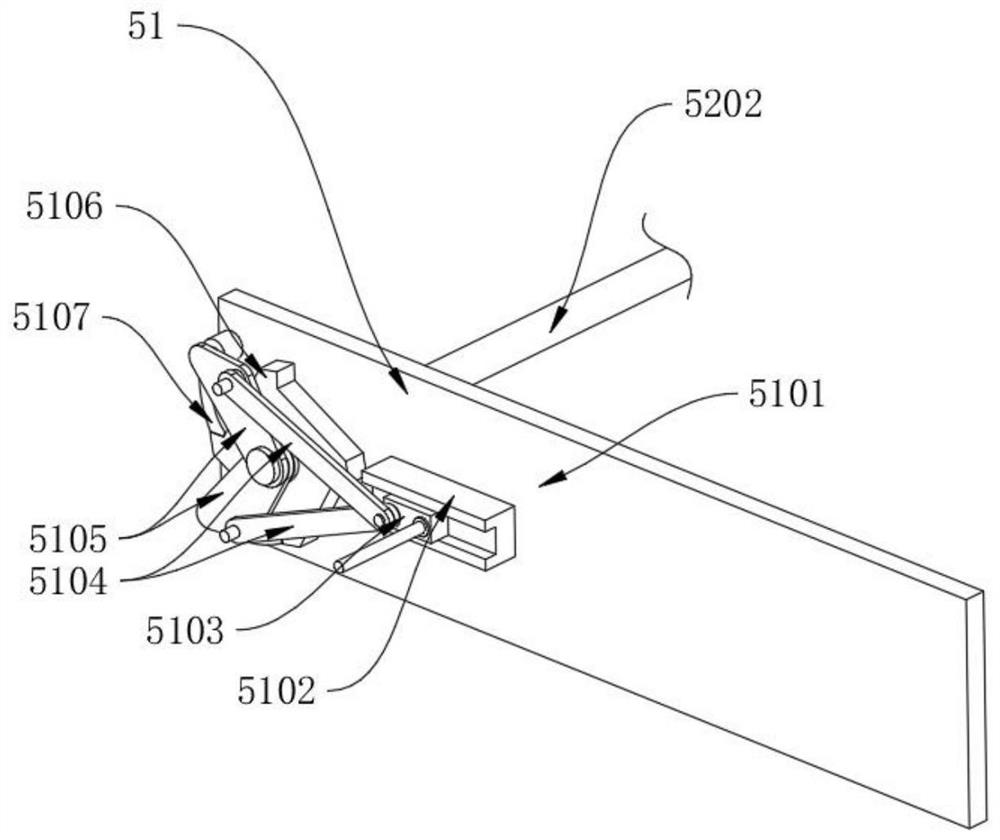

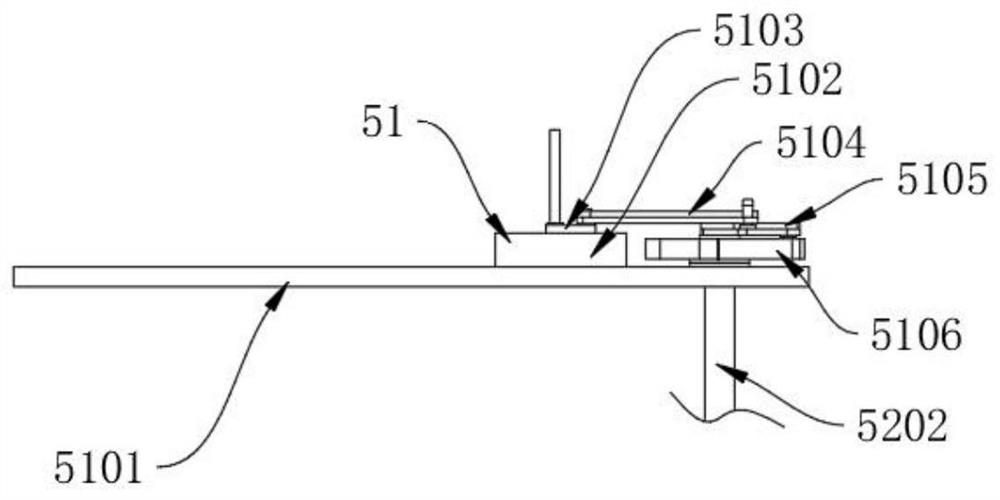

[0044] like Figure 1-7 As shown, a flat mop cleaning device with a transmission mechanism includes an air pressure water injection assembly 5. The air pressure water injection assembly 5 includes a connecting rod ratchet mechanism 51, a transmission gear shaft 52, a clutch 53 and a water pump 54. The connecting rod ratchet mechanism 51 is located on Stepping on the side of the pedal assembly 4, the stepping on the pedal assembly 4 is in transmission connection with the connecting rod ratchet mechanism 51, the transmission gear shaft 52 is arranged on the side of the connecting rod ratchet mechanism 51, the connecting rod ratchet mechanism 51 is in transmission connection with the transmission gear shaft 52, and the clutch 53 is located at transmission gear shaft 52 tops, and transmission gear shaft 52 is transmission-connected with clutch 53, and water pump 54 is located at clutch 53 tops, and clutch 53 is transmission-connected with water pump 54.

[0045] In this embodiment...

Embodiment 2

[0053] This embodiment is a further improvement of the previous embodiment, such as Figure 1-7 As shown, a flat mop cleaning device with a transmission mechanism includes an air pressure water injection assembly 5. The air pressure water injection assembly 5 includes a connecting rod ratchet mechanism 51, a transmission gear shaft 52, a clutch 53 and a water pump 54. The connecting rod ratchet mechanism 51 is located on Stepping on the side of the pedal assembly 4, the stepping on the pedal assembly 4 is in transmission connection with the connecting rod ratchet mechanism 51, the transmission gear shaft 52 is arranged on the side of the connecting rod ratchet mechanism 51, the connecting rod ratchet mechanism 51 is in transmission connection with the transmission gear shaft 52, and the clutch 53 is located at transmission gear shaft 52 tops, and transmission gear shaft 52 is transmission-connected with clutch 53, and water pump 54 is located at clutch 53 tops, and clutch 53 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com