Patents

Literature

51results about How to "Ease of delivery" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Digital photo services in recreational parks

InactiveUS20120198371A1Decrease priceEase of deliveryData processing applicationsInput/output processes for data processingUnique identifierDigital pictures

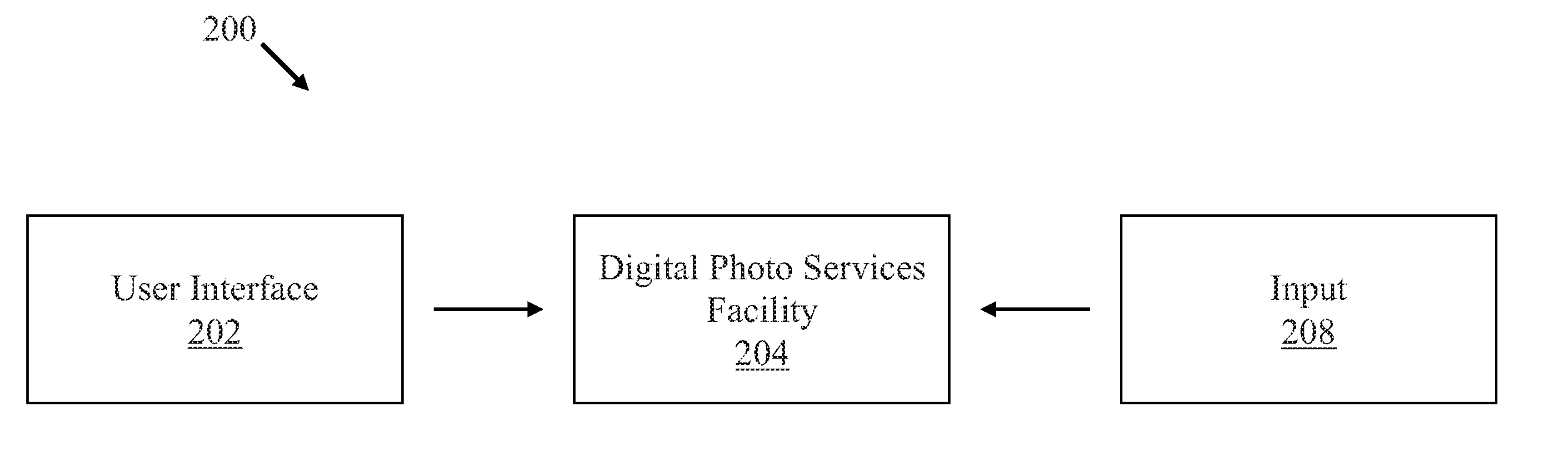

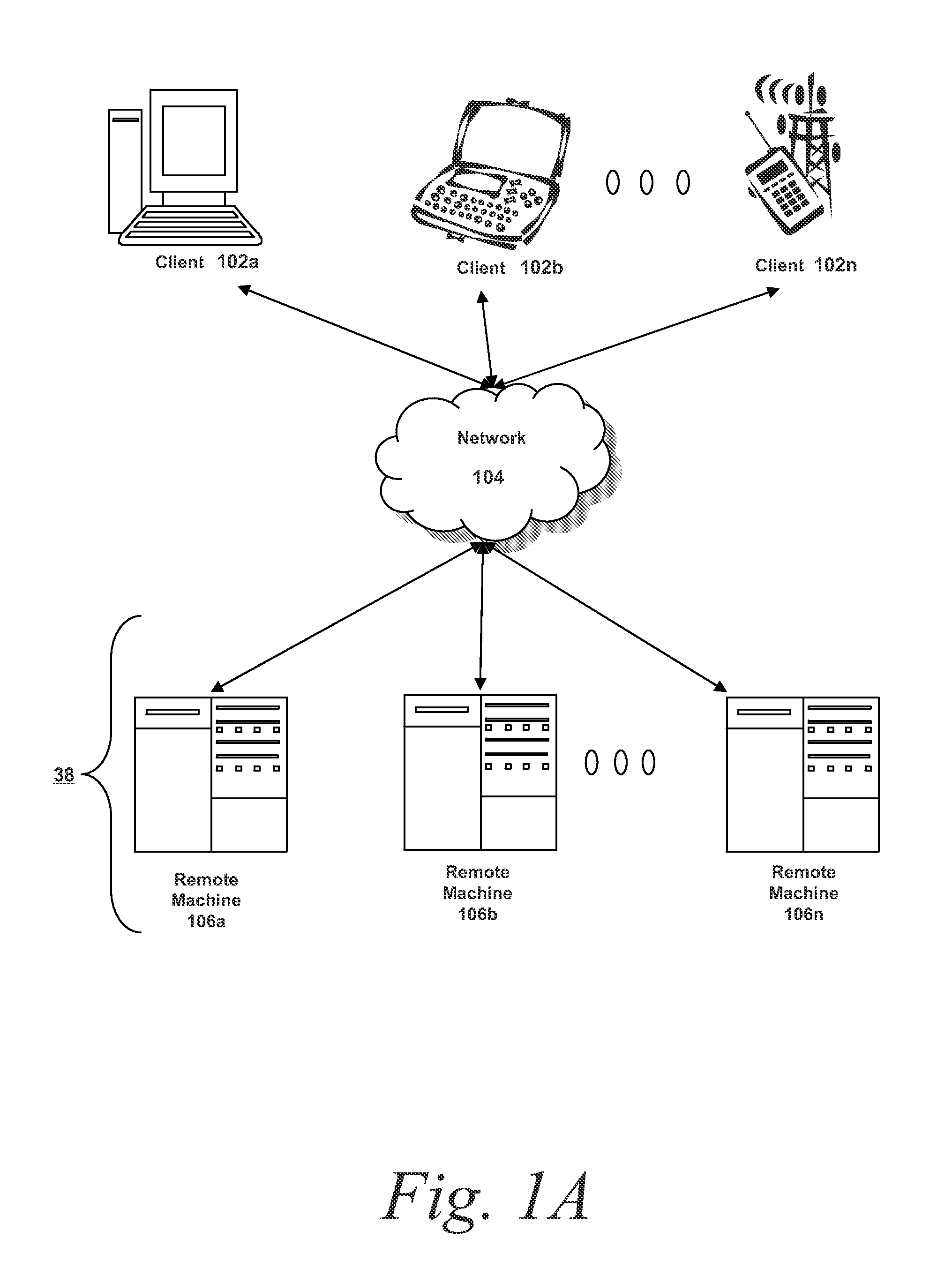

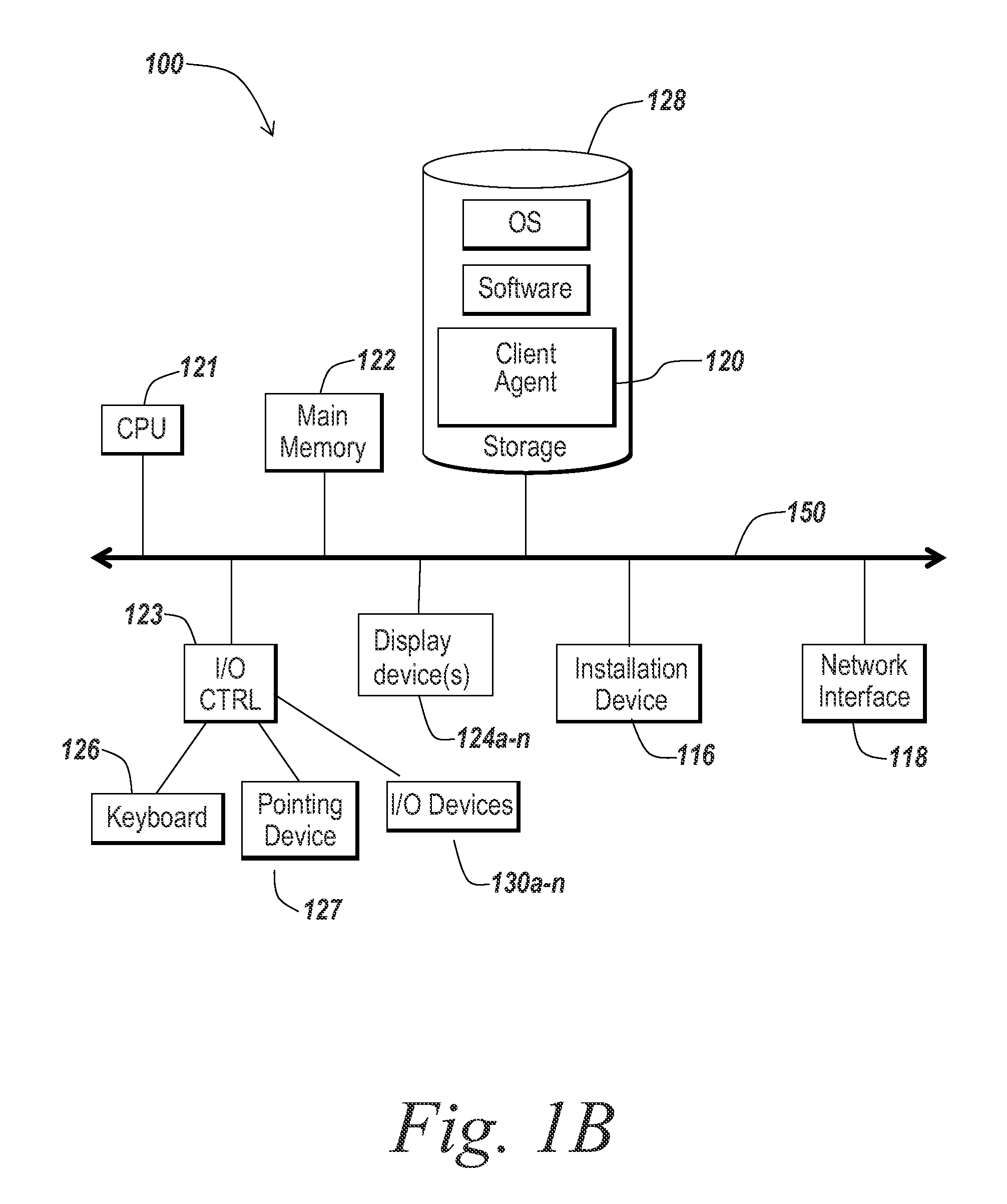

The present disclosure describes systems and methods for delivering digital photos where digital delivery is eased by a user interface. In an aspect of the invention, a system may include a digital photo service facility that stores digital photos wherein the digital photos are captured by a remote input device and a user a user interface to the digital photo services facility, wherein the user interface is used to access the digital photos by inputting at least one of a unique identifier or a live image of the user for facial recognition.

Owner:LIWERANT GAD

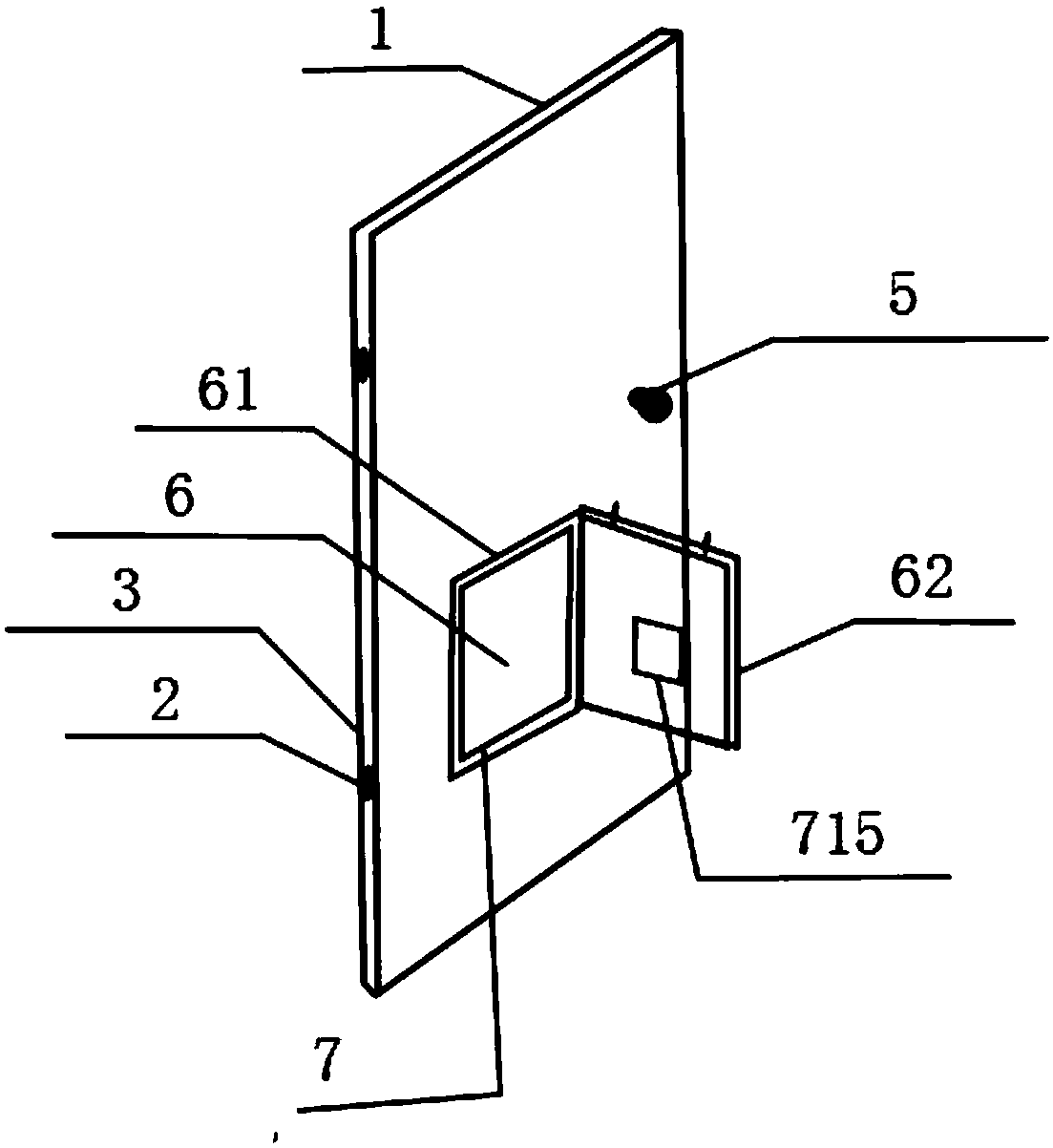

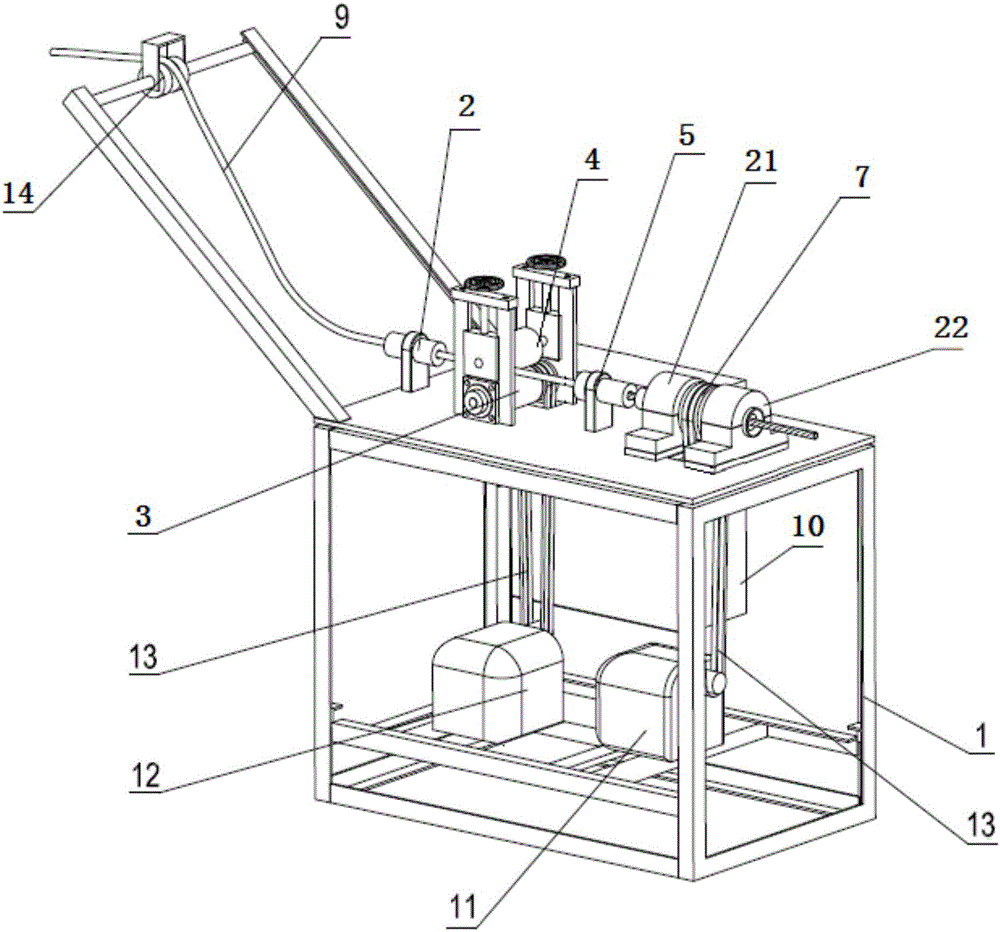

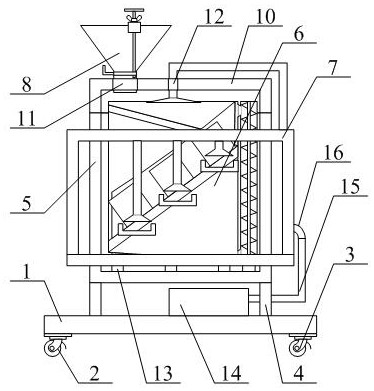

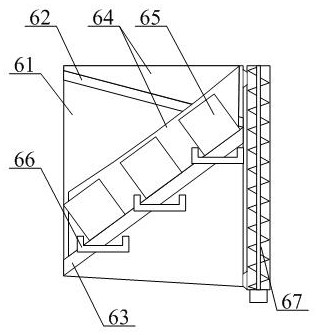

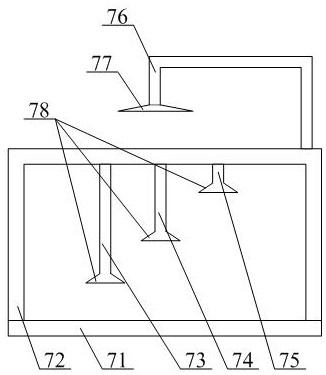

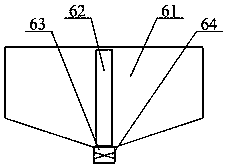

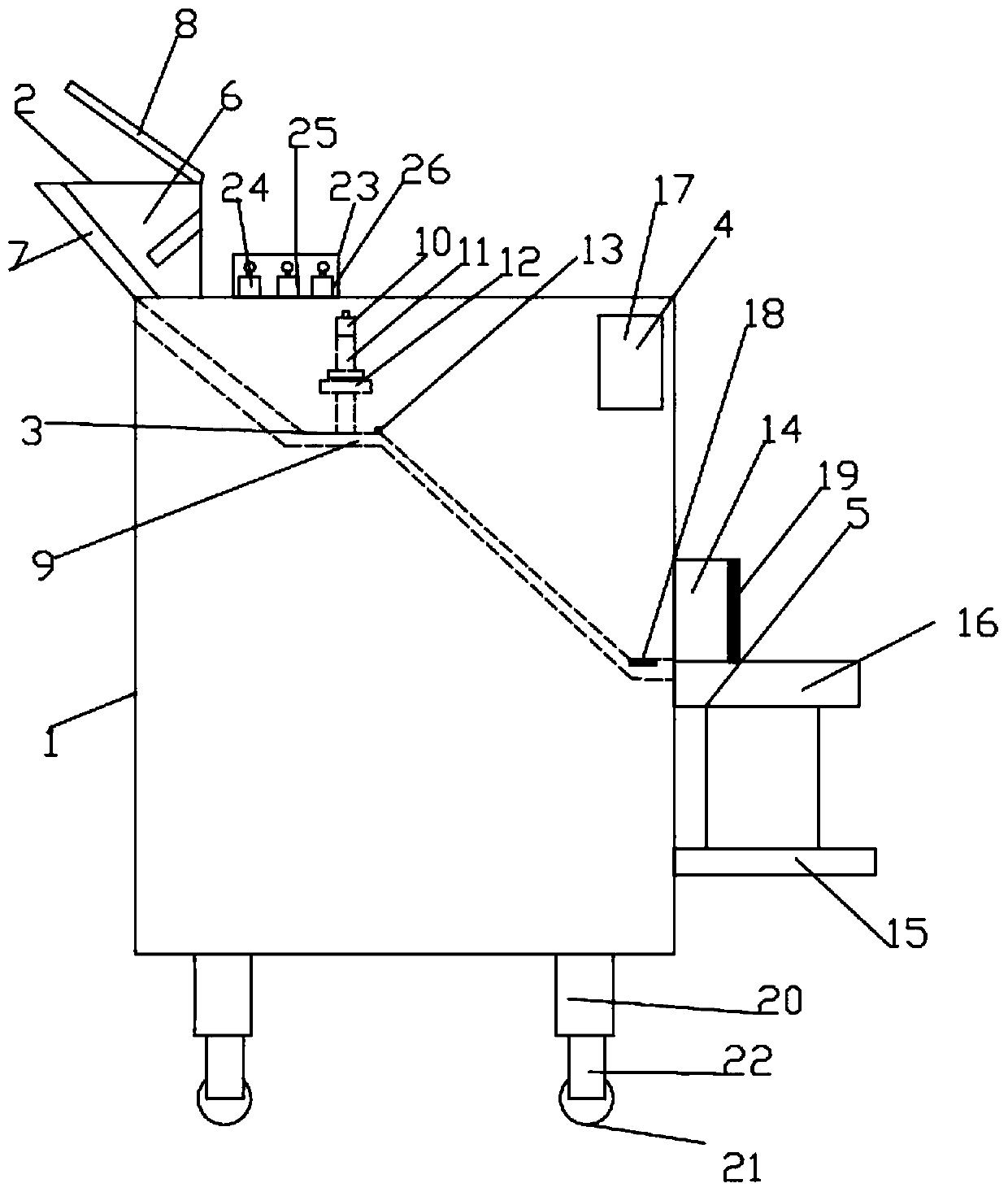

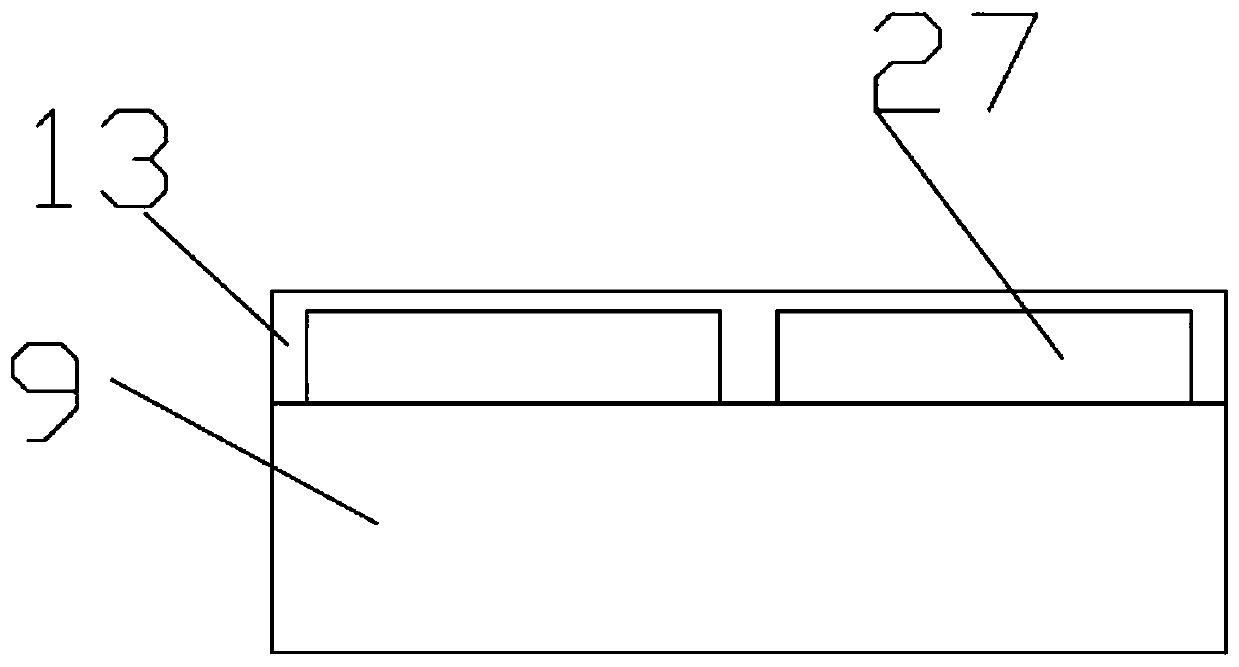

Intelligent object receiving and sending system

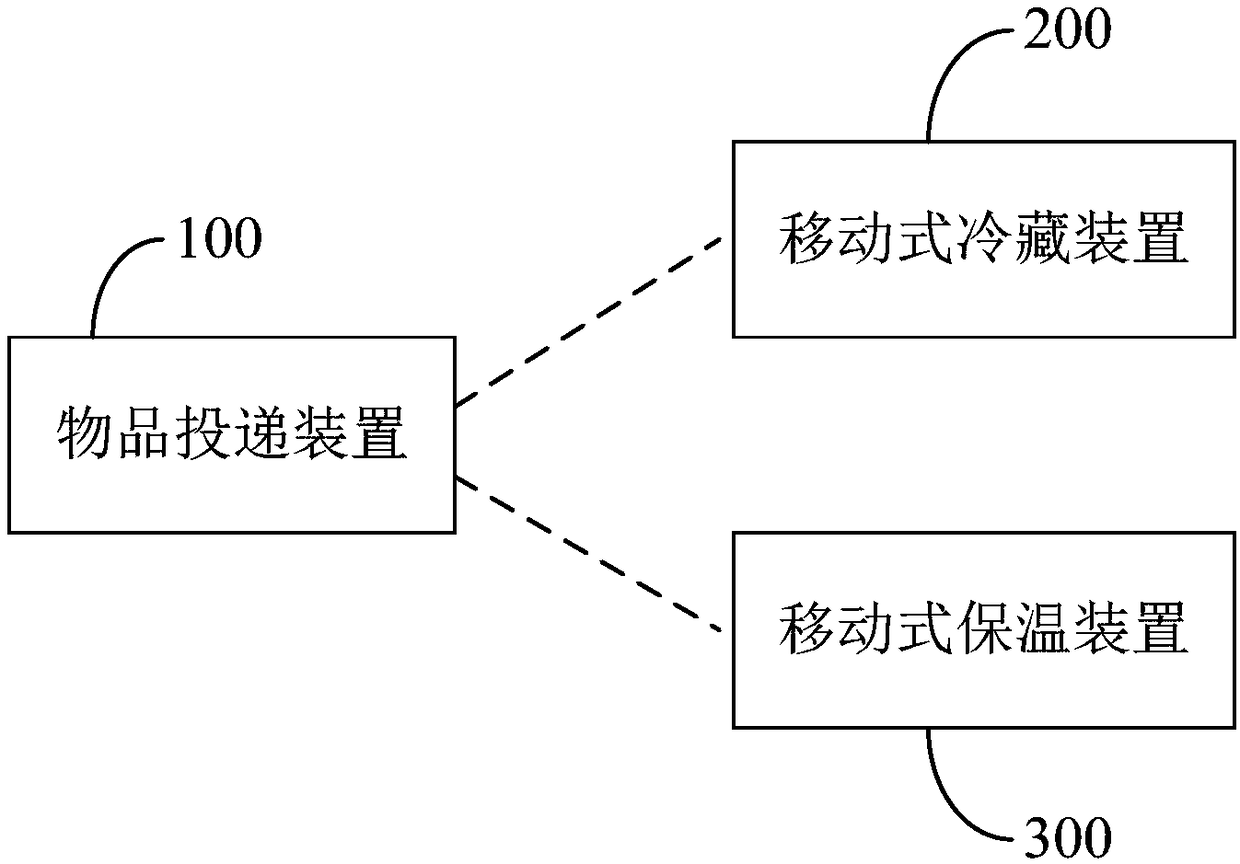

ActiveCN108257316ASave the transfer processMeet delivery needsDomestic cooling apparatusLighting and heating apparatusEngineeringLinkage concept

The invention belongs to the technical field of smart homes and provides an intelligent object receiving and sending system. The system includes an intelligent delivery device arranged on a main userdoor, a mobile refrigerating device and a mobile heat preservation device, wherein the mobile refrigerating device and the mobile heat preservation device are arranged in a user room; a postman can directly put objects into the mobile refrigerating device or the mobile heat preservation device through an intelligent window of the object delivery device, the operation is very convenient and fast, atransfer process of a traditional delivery box is omitted, and the reliability is high. Additionally, the mobile refrigerating device or the mobile heat preservation device can achieve refrigerationor heat preservation of the objects and meet delivery demands for fresh goods and cooked food products; meanwhile, the mobile refrigerating device or the mobile heat preservation device can also be moved to preset positions to provide convenience for users to take food. By means of the intelligent object receiving and sending system, there is no need for a receiver and a sender to make an order for delivery, and the efficiency is greatly improved. Through an extended function of the object delivery device, linkage with other equipment in the user room can also be achieved, and for instance, lights can be automatically turned on after an intelligent door lock is unlocked for the users.

Owner:宁炎声

Phase change filling sealing material with built-in graphite fibers

ActiveCN106240037AEasy to achieve fire resistanceImprove sealingSynthetic resin layered productsMaterial analysis by optical meansFiberLiquid state

The invention relates to the technical field of materials. A phase change filling sealing material with built-in graphite fibers comprises the following components by mass percent: 65%-80% of thermal conductive particles, 5%-20% of low-melting-point solid resin, 10%-20% of liquid resin and 0.02%-2% of a coupling agent, wherein the thermal conductive particles include graphite fibers, and the weight of the graphite fibers accounts for 30%-60% of the total weight of the thermal conductive particles. When the melting point of the phase change filling sealing material is lower than that of the low-melting-point solid resin, the solid state is kept all the time; when the melting point of the phase change filling sealing material is higher than that of the low-melting-point solid resin, the phase change filling sealing material can be heated to be subjected to phase change to be changed into liquid state or paste state at the temperature, so that the surface of a device can be moistened to a greater degree, contact heat resistance is reduced to be lowest, and a thermal conductive gap filling property of thermal conductive resin or a graphite flake can be acquired.

Owner:SHANGHAI ALLIED PLASTIC IND

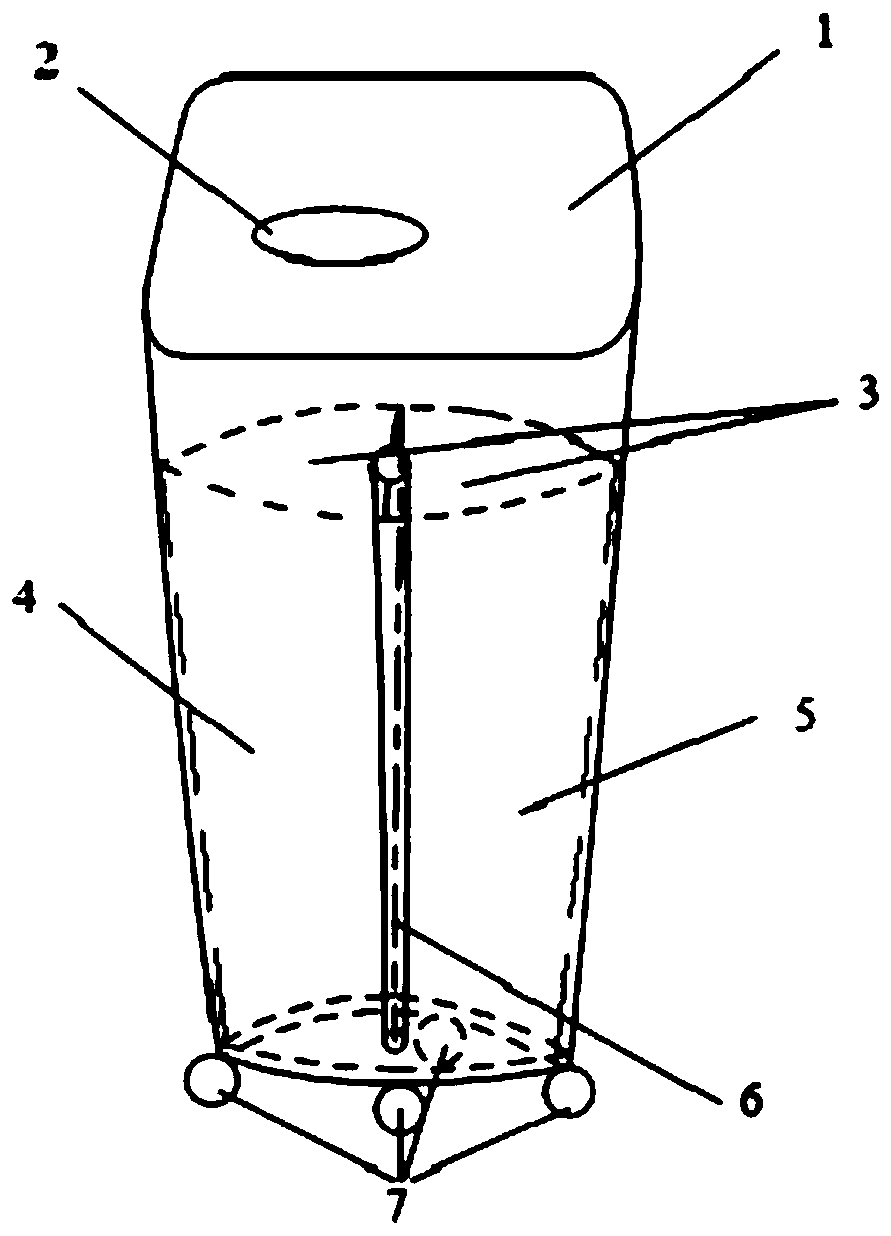

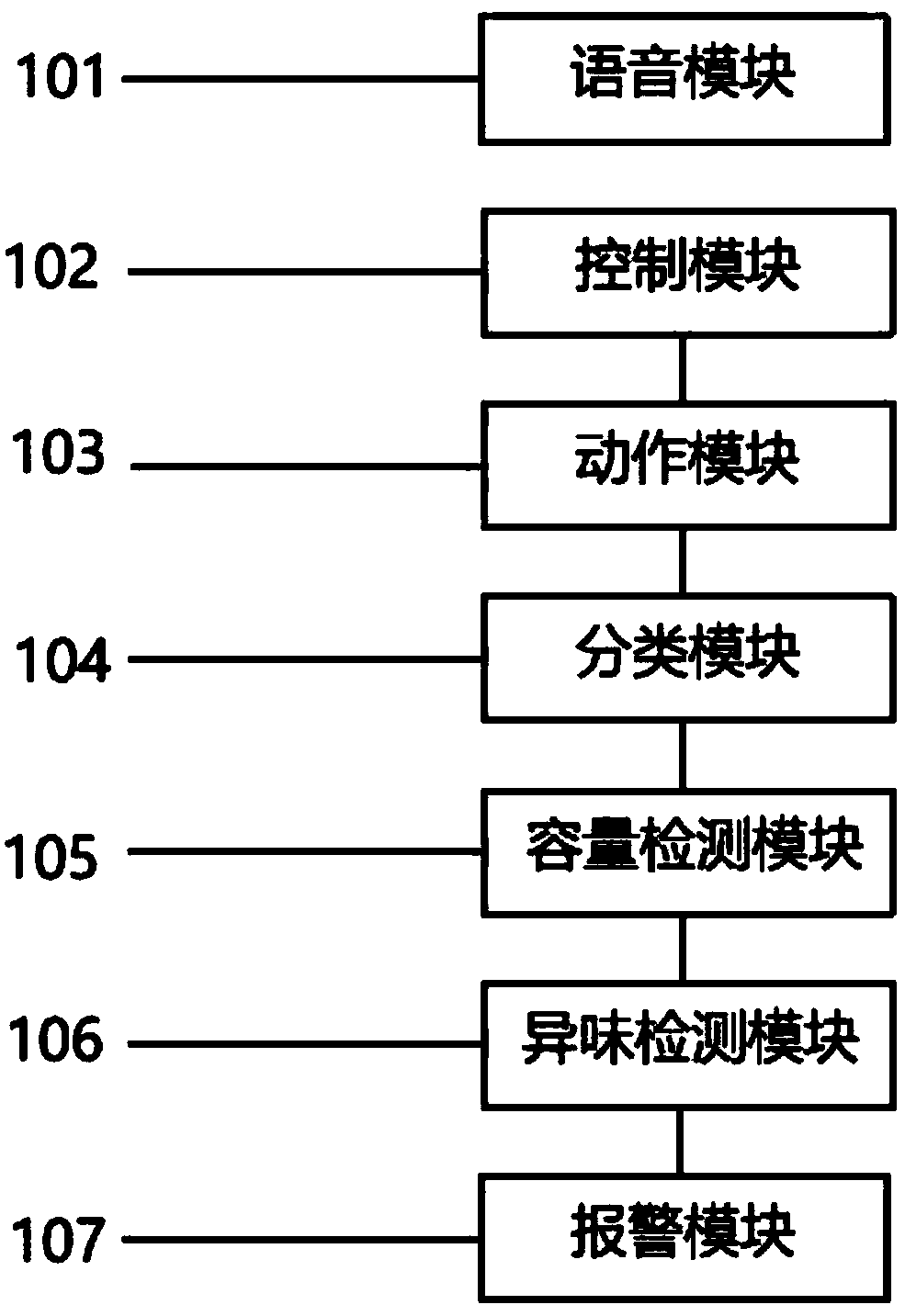

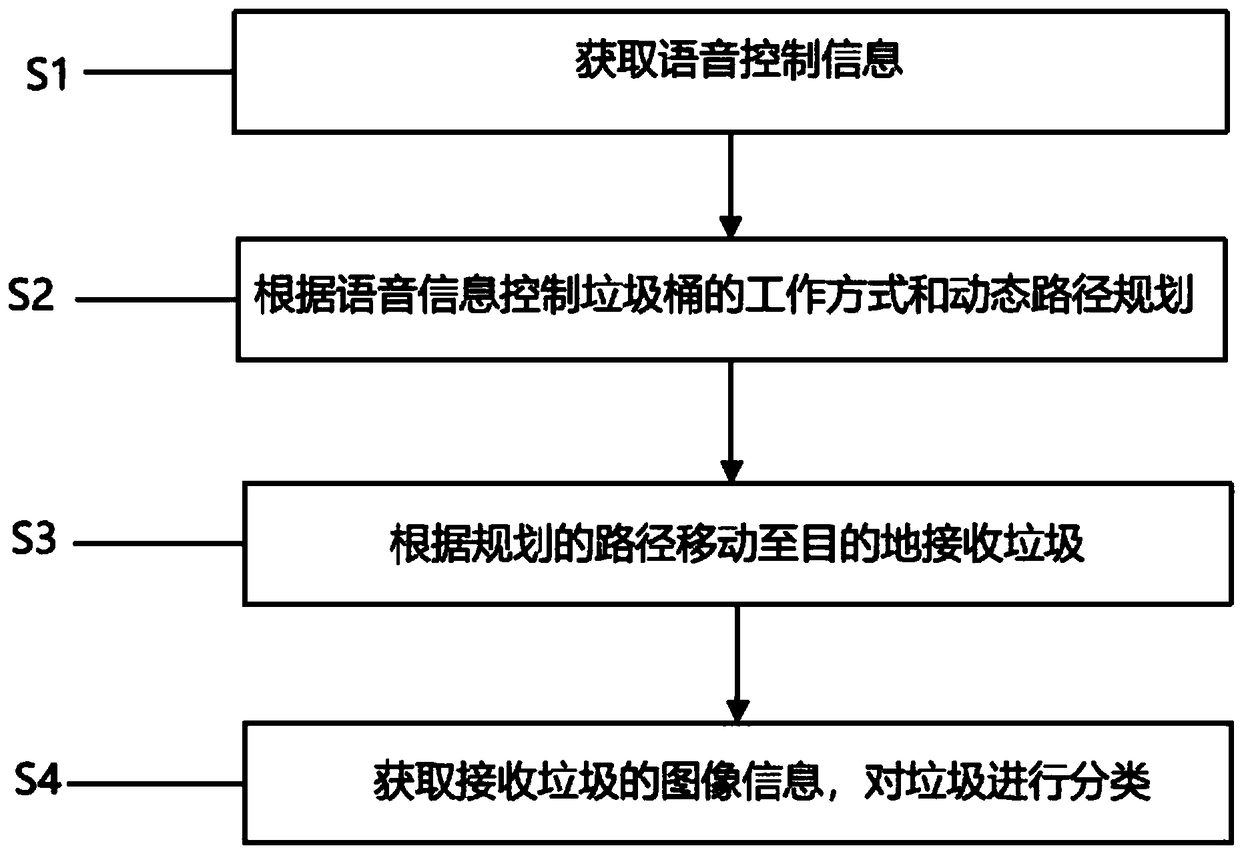

Control device and method for intelligent trash can and intelligent trash can

InactiveCN109460028AEase of deliveryPrevent overflowPosition/course control in two dimensionsRobot learningUtilization rate

The invention belongs to the technical field of trash cans, and particularly relates to a control device and method for an intelligent trash can and the intelligent trash can. The control method for the intelligent trash can comprises the steps that voice control information is acquired; the working mode and dynamic path planning of the trash can are controlled according to the voice information;according to a planned path, the trash can moves to the destination to receive trash; image information of trash receiving is acquired, trash sorting is conducted, by utilizing technologies of robot learning, data mining and the like, the intelligent trash can works on multiple occasions under dynamic path planning, and the moving mode reduces the using number of trash cans; trash throwing can beconveniently achieved, auxiliary functions of pushing of spilling alarming information and unpleasant odor removing increase the resource classification recovering utilization rate and avoid the phenomenon that trash spills, the intelligent and humanized design provides great design for life demands of people, and pursuing for the living quality is improved.

Owner:GREE ELECTRIC APPLIANCES INC

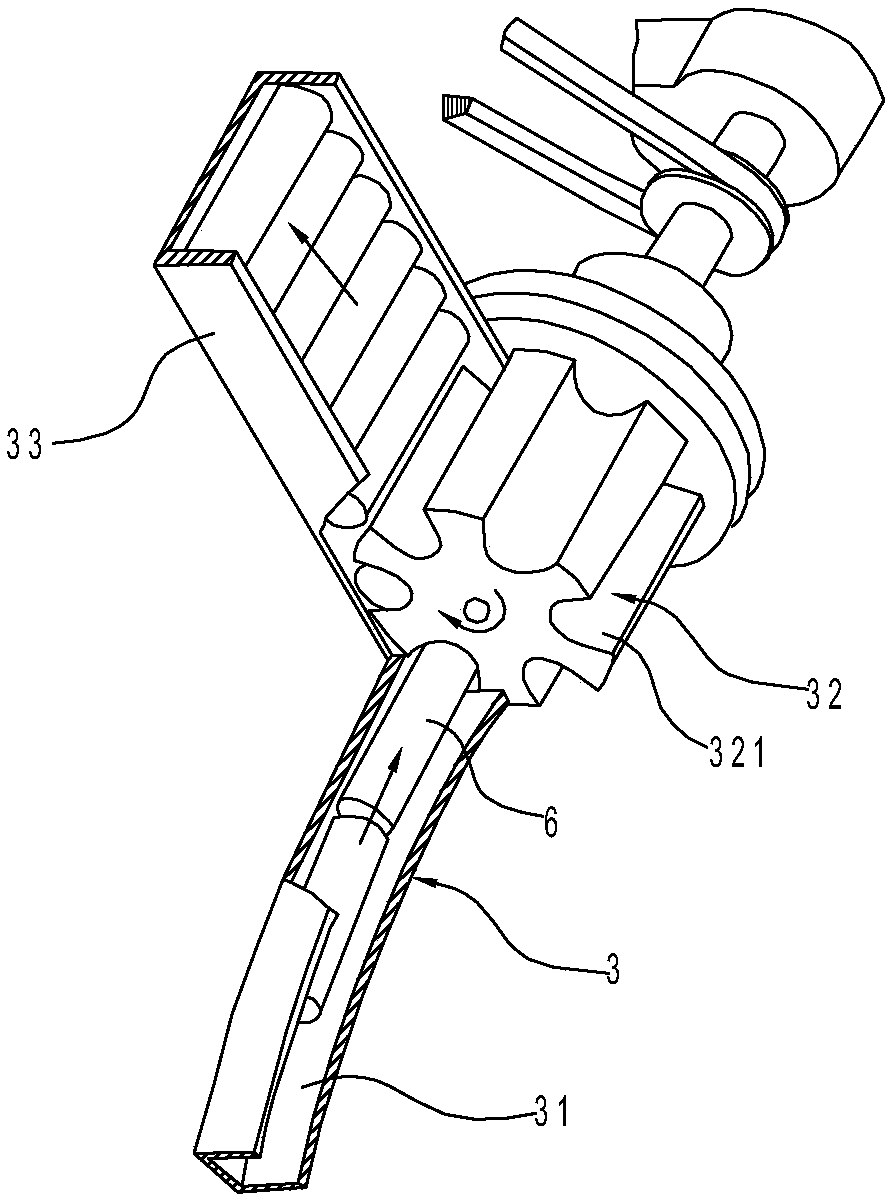

Rotary cutter for bunch pipe production

ActiveCN105922322AAchieve protectionAchieve insulationMetal working apparatusEngineeringMechanical engineering

The invention relates to the field of machinery. The rotary cutter for bunch pipe production comprises a rotary cutter body; the rotary cutter body includes a frame; a cutting piece is arranged on the frame, and is provided with a first through hole penetrated front and back; a cutter is arranged on the inner wall of the first through hole; the cutting piece is connected with a first motor through a transmission mechanism; and a rotating center line of the cutting piece is parallel to the center axis direction of the first through hole. The rotary cutter realizes movement of a cutter through rotation of the cutting piece to spirally cut a pipe-shaped body so as to conveniently produce a bunch pipe to wind a lead, and realizes the lead protecting and insulating effects.

Owner:SHANGHAI RICHENG ELECTRONICS

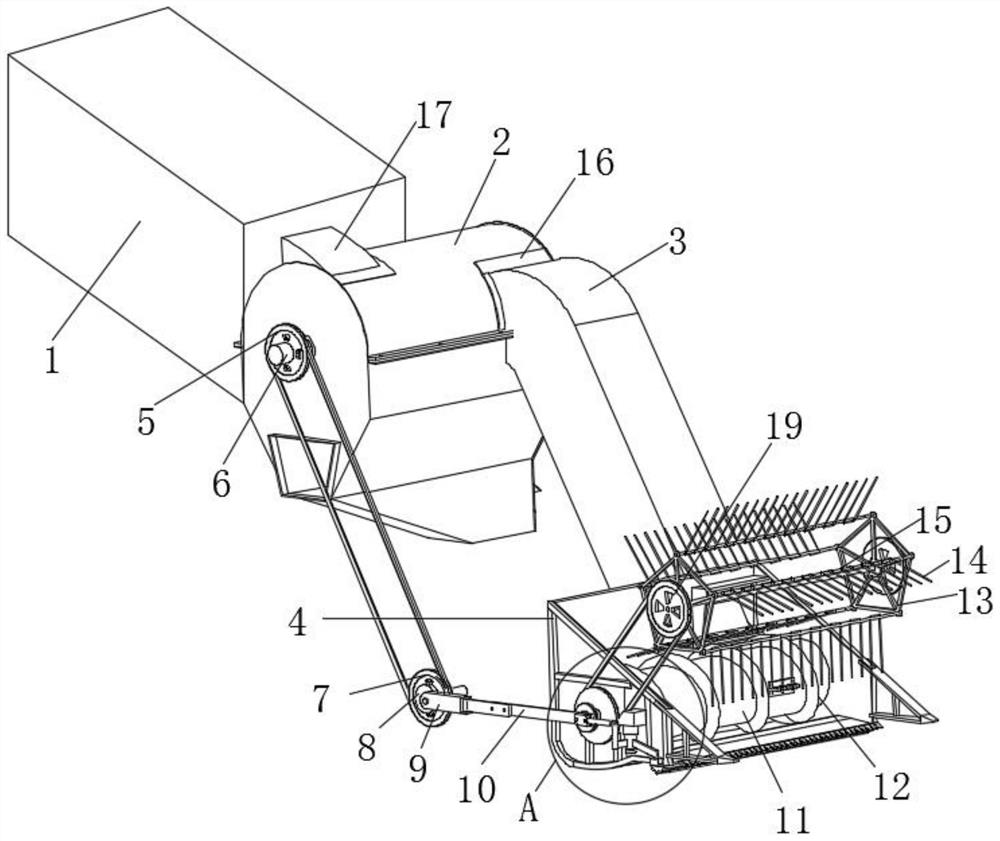

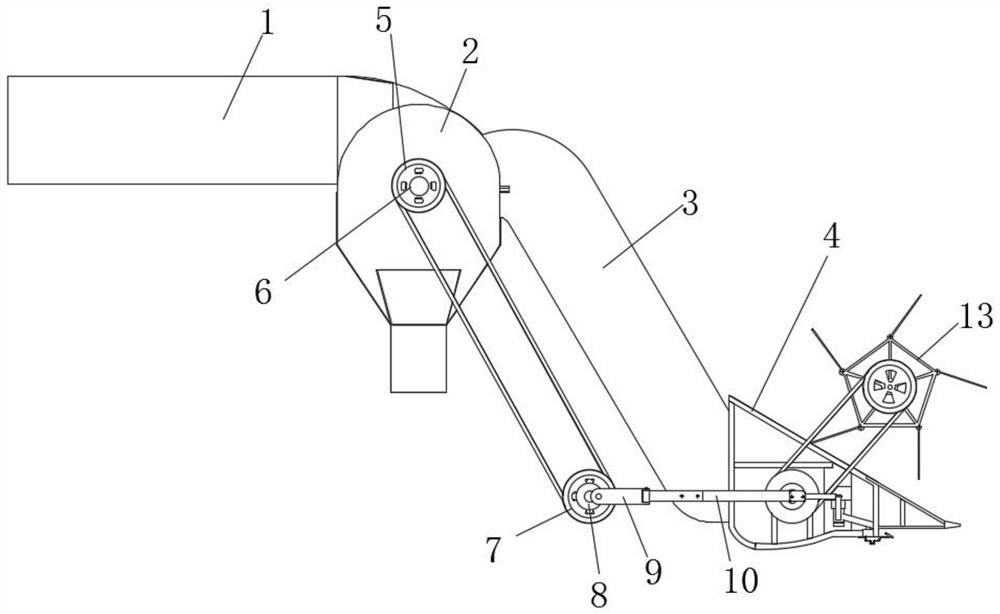

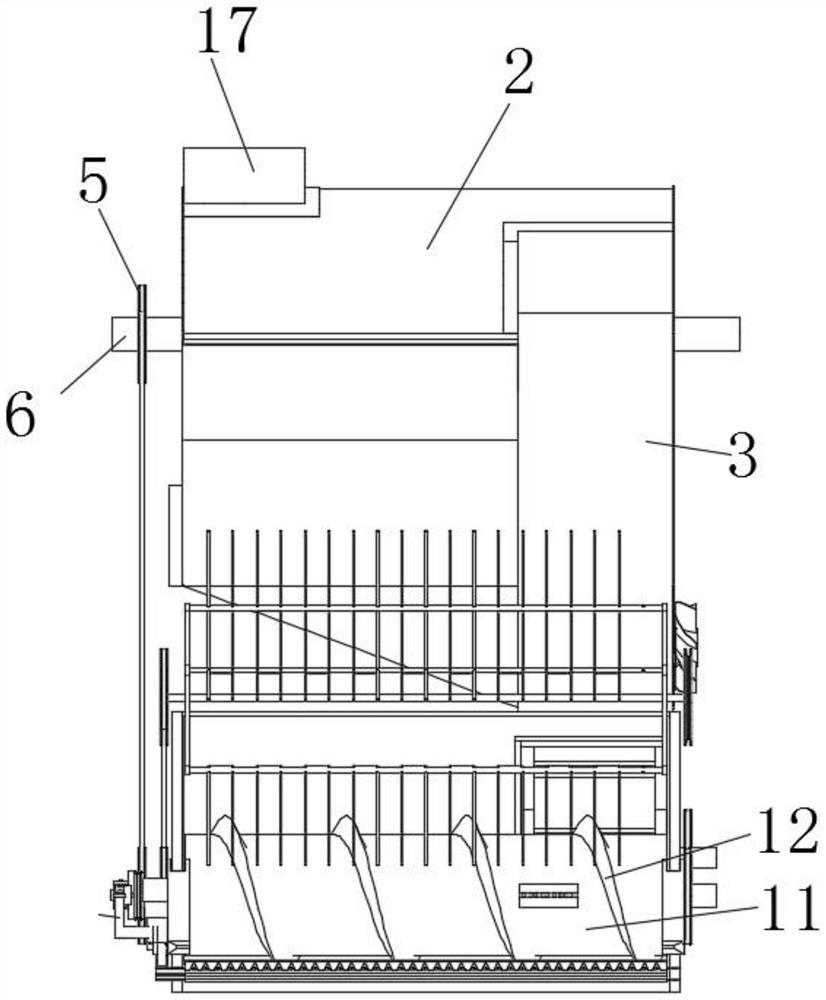

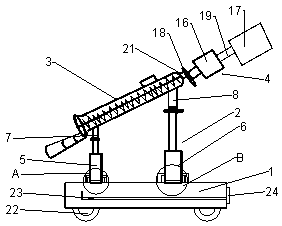

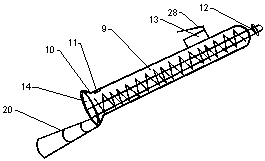

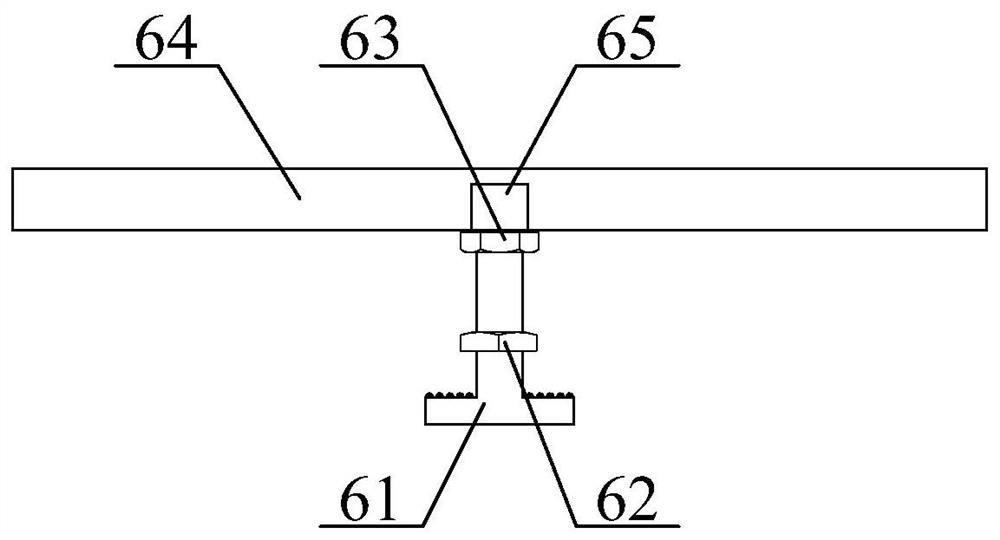

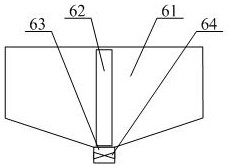

Crop straw harvesting and bundling machine and working method thereof

ActiveCN112425350ATo achieve the purpose of cuttingRealize the delivery workReaper-bindersAgricultural scienceAgricultural engineering

The invention discloses a crop straw harvesting and bundling machine. The machine comprises a crushed material bundling box and a material collecting box, a crushed material pipe is arranged at one end of the top of the material collecting box, the crushed material bundling box is arranged at one side of the material collecting box, the material collecting box communicates with the crushed material bundling box through the crushed material pipe, and a feeding port is formed at the side wall of one end of the material collecting box; and a conveying frame is arranged at one side of the bottom of the feeding port, after crop straw enters the material collecting box, a driving wheel drives a crushing wheel to rotate through a belt, a crushing shaft is driven to rotate through rotation of thecrushing wheel, the crop straw entering the material collecting box is crushed, and fruits and straw are separated. The fruits leak out through a leaking plate and are collected, the straw enters thecrushed material bundling box through the crushed material pipe to achieve bundling work, straw collecting and bundling work is conducted while the crop straw and the fruits are separated, straw scattering is avoided, straw centralized treatment is facilitated, and the phenomenon that traditional straw is not easy to treat and incinerate on site is avoided.

Owner:ANHUI DENGSHI MACHINERY MFG

Municipal engineering landscaping trimmer capable of being adjusted at multiple angles

InactiveCN114158345AFacilitates horizontal pruning workEasy pruning workMowersElectric machineryLandscaping

The invention provides a multi-angle adjustable municipal engineering landscaping trimmer which comprises a movable base, universal moving wheels, directional moving wheels, a pushing rod, a collecting box, a pluggable collecting and guiding box structure, a rotatable supporting and protecting plate structure, an adjustable fixed power frame structure, a compressible buffering and pushing reset plate structure, a sliding hole and an inverted L-shaped fixing plate. The front surface of the left side of the lower end of the movable base and the rear surface of the left side of the lower end of the movable base are respectively in bolted connection with the universal moving wheels. Through the arrangement of the U-shaped frame, the rotating hole, the rotating plate, the power motor mechanism, a rotating locking rod and a locking ring, the locking ring can be loosened in the using process, the rotating plate and the power motor mechanism are rotated, meanwhile, a pruning cutter is rotated to the front of the movable base, and the side face of a plant can be pruned conveniently in the pruning process.

Owner:安徽绿泉生态环境建设有限公司

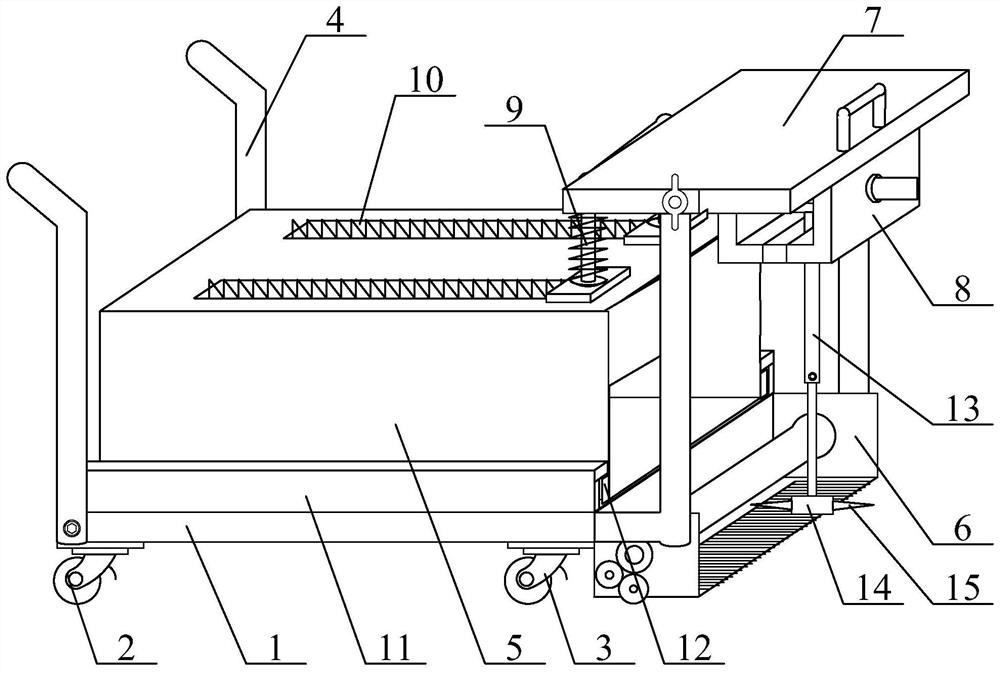

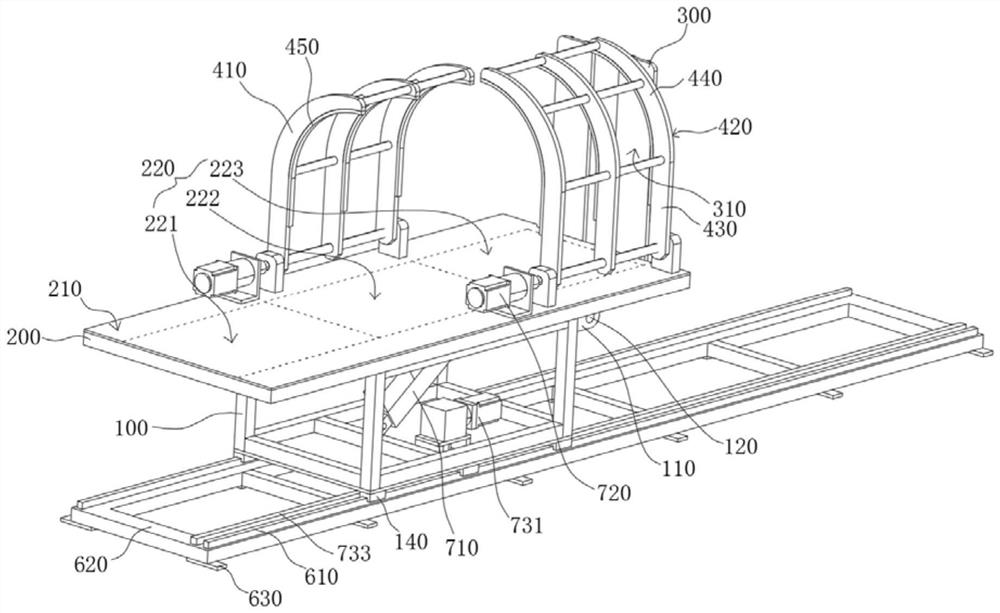

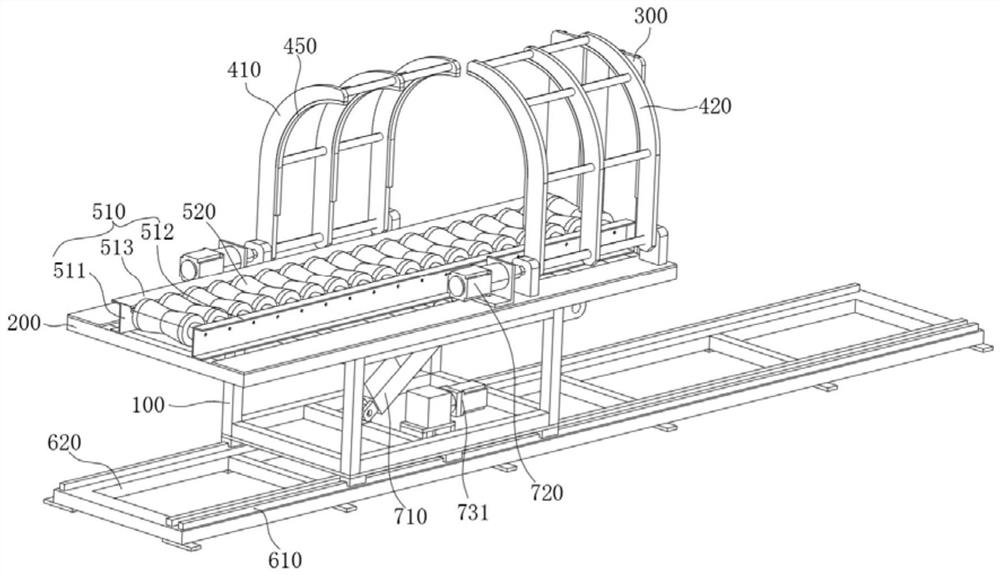

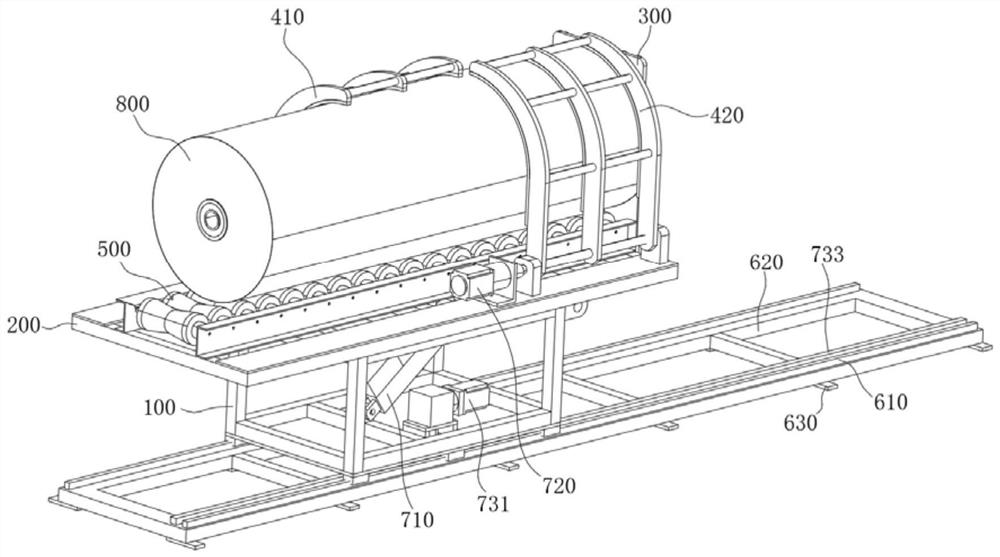

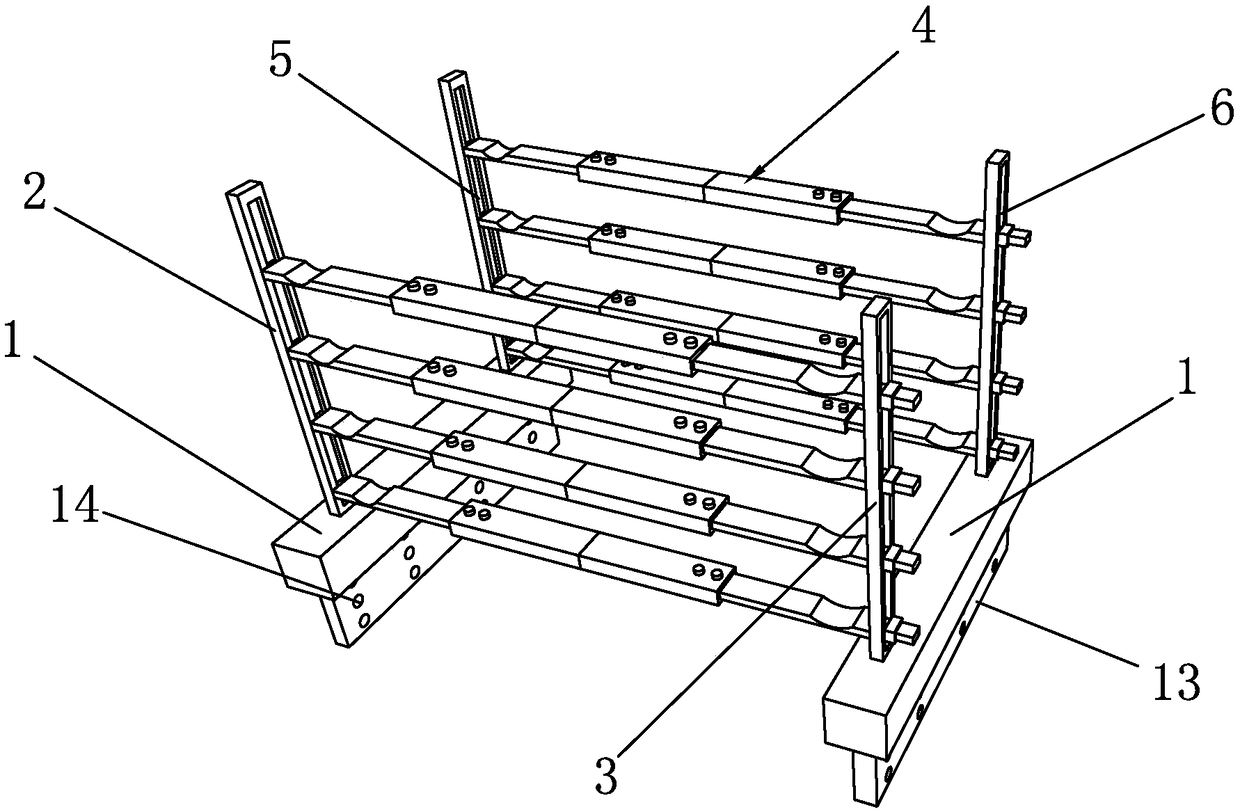

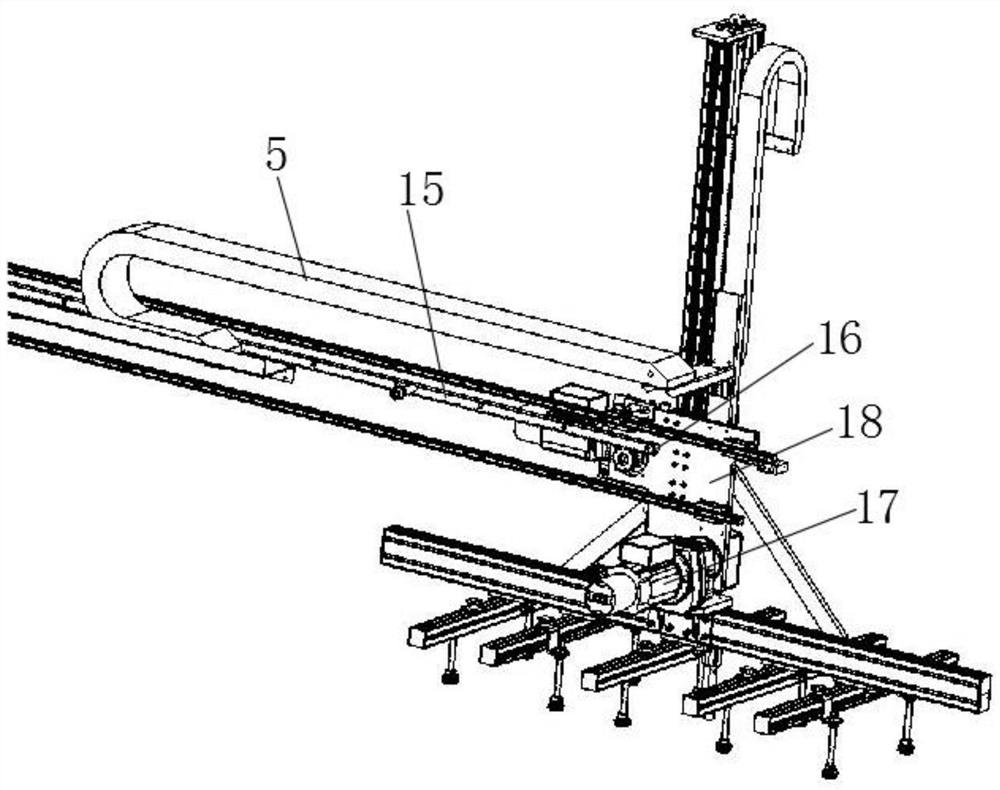

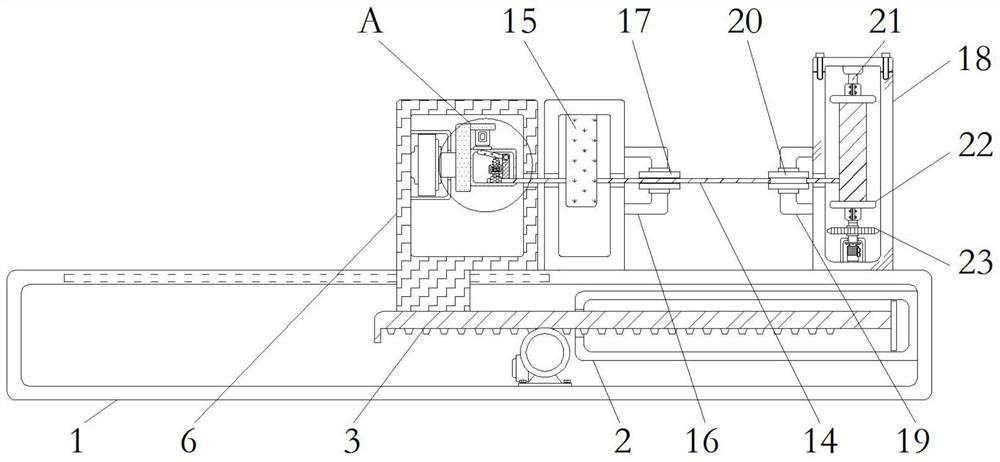

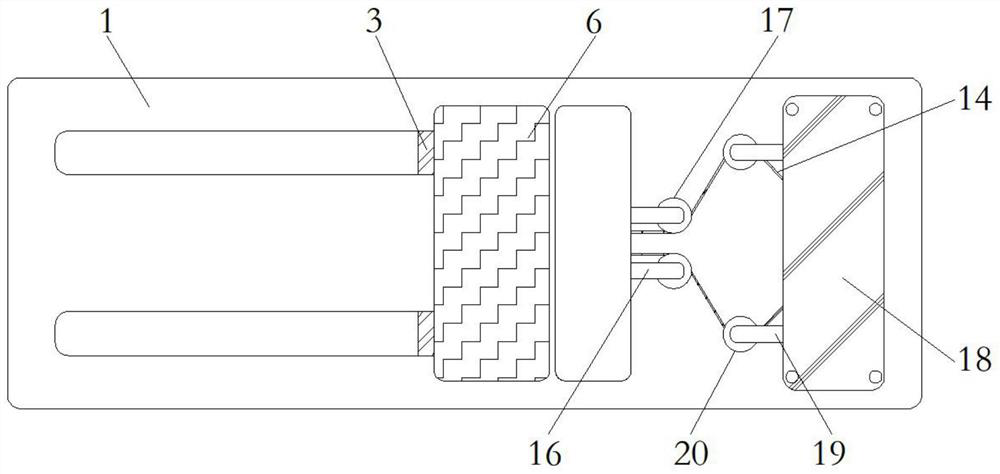

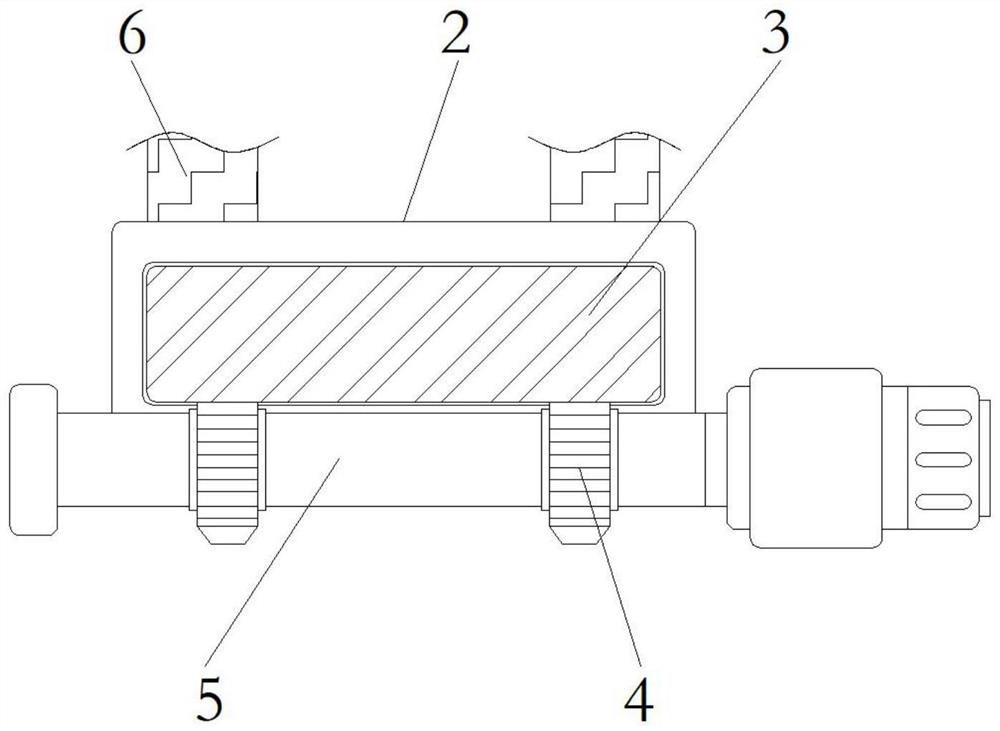

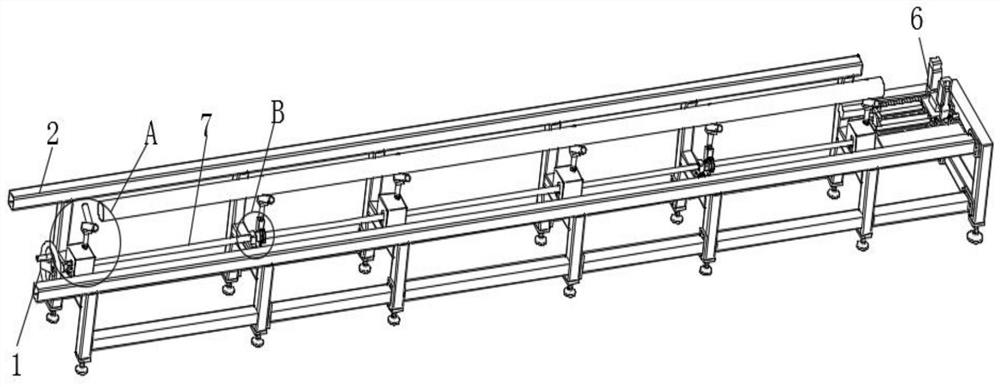

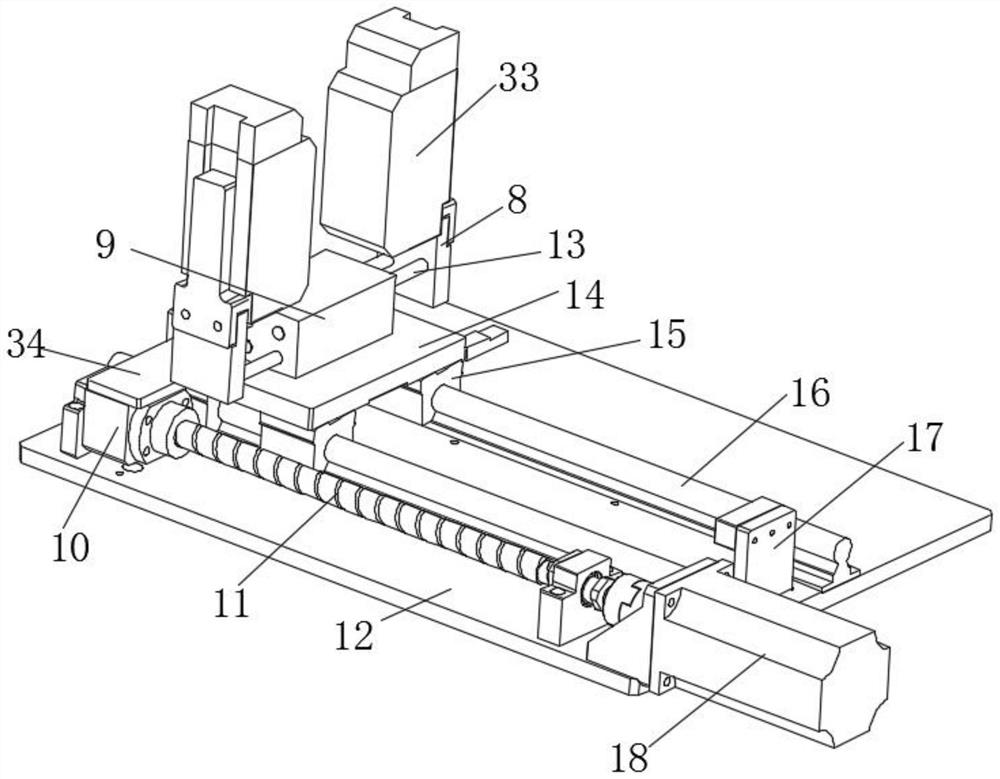

Turnover device and coiled material turnover method

ActiveCN112777284AGuaranteed stabilityEase of deliveryConveyorsControl devices for conveyorsRobot handEngineering

The invention provides a turnover device and a coiled material turnover method, and relates to the technical field of coiled material turnover. The turnover device comprises a rack and a turnover table hinged to the rack, the rack is provided with a first driving assembly, and the driving end of the first driving assembly is connected with the turnover table; and a containing area is arranged on the top face of the turnover table, a blocking base is fixedly connected to the tail end of the containing area, a rotating piece is hinged to the side portion of the containing area, a second driving assembly is installed on the turnover table, and the driving end of the second driving assembly is connected with the rotating piece. The coiled material turnover method adopts the turnover device to overturn a coiled material. According to the turnover device, the head end of the containing area is in an open state, the coiled material can be directly conveyed to the turnover table from a previous station through the head end of the containing area, an additional mechanical arm is not needed to convey the coiled material from the upper portion, the coiled material conveying convenience is high, and the requirement for a related conveying device of a coiled material machining line is low.

Owner:北京城创新智科技有限公司

Heavy-duty mine car cargo tank coating device

PendingCN111760738AEase of deliveryAvoid affecting work efficiencyPretreated surfacesDirt cleaningAir pumpDust control

The invention provides a heavy-duty mine car cargo tank coating device. The heavy-duty mine car cargo tank coating device comprises a coating base, inverted-T-shaped supporting rods, grooves, conveying rollers, first supporting plates, a guided supporting frame structure, a blowing dust collection frame structure, an observable drying frame structure, a collectable adsorption scraping frame structure, conveying motors, fixed plates, wing bolts, arc-shaped plates, a spraying box, a coating pipe, a coating box, a coating pump, an air pump, a connecting pipe, a suction fan assembly and a supporting roller. The inverted-T-shaped supporting rods are connected to the four corners of the lower end of the coating base through bolts. Through arrangement of a U-shaped supporting frame, adsorption blocks, a scraping seat, a scraping blade, the coating base, the grooves and the supporting roller, the heavy-duty mine car cargo tank coating device can scrape off coatings on the surfaces of the supporting roller through contact of the scraping blade and the supporting roller in the coating process of cargo tanks, and the situation that the coating quality of the cargo tanks is affected after different types of coatings are mixed is avoided.

Owner:山东华海新材料有限公司

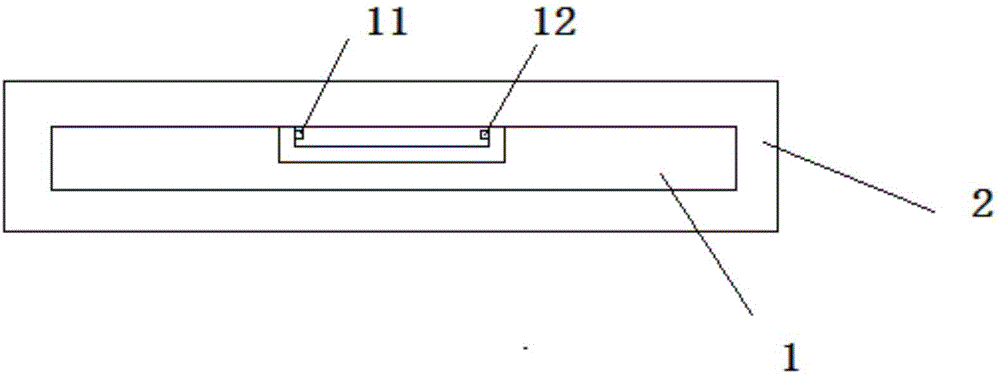

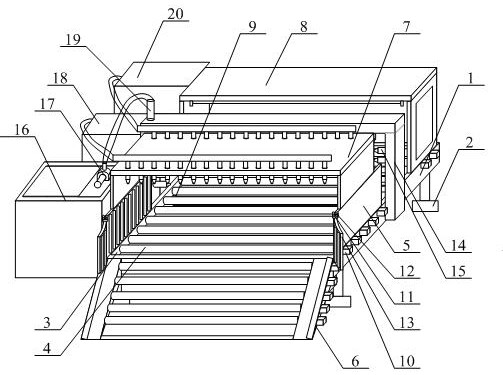

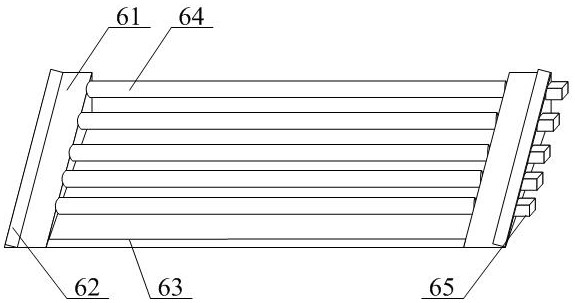

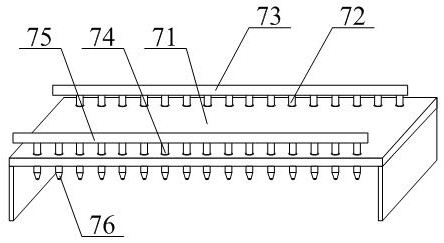

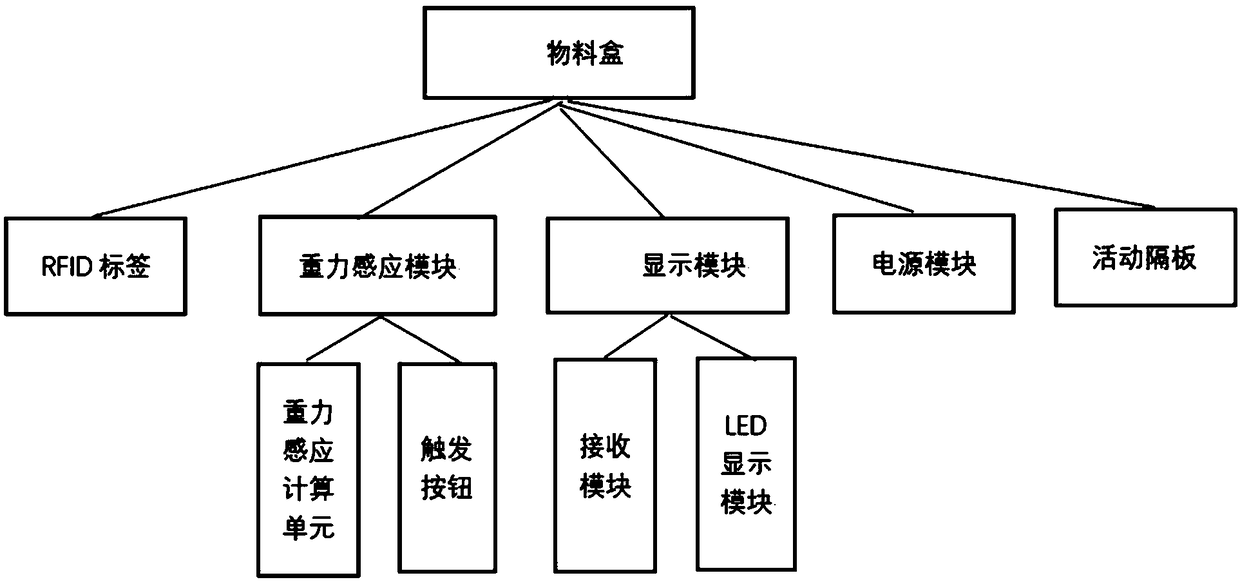

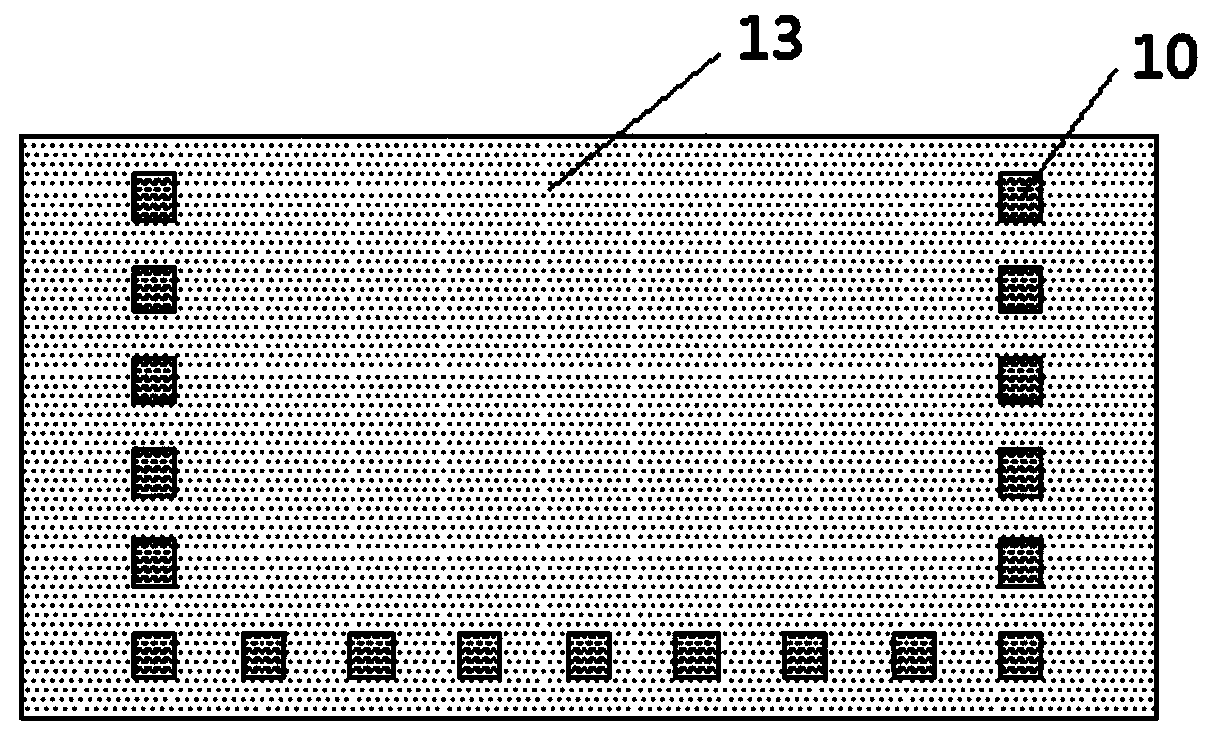

Intelligent material box

InactiveCN109229888AAutomate distributionAchieve accessContainer decorationsLevel indicationsRelevant informationHuman power

The invention relates to the field of intelligent production and manufacturing, and discloses an intelligent material box. The problems are solved that traditional material boxes only have a materialstorage function, a manual measurement and recording mode needs to be adopted for taking and placing materials, the labor is wasted, and errors are easily made. The intelligent material box comprisesa box body, an RFID tag, a gravity sensing module, a display module and a power module; the RFID tag is used for recording related information of the materials in the box body; the gravity sensing module is used for calculating the quantity of the materials in the box body according to the weight of a single material; the display module is used for displaying the quantity of the materials in the box body; the power module is used for supplying power to the display module. The intelligent material box is suitable for storing the materials or finished products.

Owner:SICHUAN ILINK TECH CO LTD

Multifunctional code spraying machine for computer production and processing

InactiveCN113043755AEasy to adjust workHeight adjustableTypewritersStructural engineeringBoard structure

The invention provides a multifunctional code spraying machine for computer production and processing. The machine comprises a control cabinet body, a ventilation hole, operation holes, a code spraying box, a code spraying mechanism, a liftable push frame structure, a telescopic code spraying support structure, a slidable adjustment conveying seat structure, an adjustable rotation guide plate structure, a fixed seat, movable brake wheels, threaded rods, adsorption seats, a supporting illumination rod, an illumination and illumination lamp beads, and the ventilation hole is formed in the lower part of the front surface of the control cabinet body; and the operation holes are formed in the left side and the right side of the upper portion of the front surface of the control cabinet body respectively. According to the machine, through arrangement of the code spraying box, the code spraying mechanism, the fixed seat, the telescopic seat, a sliding rod, a sliding hole and a first locking nut, the first locking nut can be loosened in the use process, then a telescopic seat is adjusted to drive the code spraying mechanism to move at the same time, the code spraying mechanism can be adjusted conveniently in the use process, and the code spraying position adjustment work in the working process is facilitated.

Owner:青岛自主可控工业技术研究院有限公司

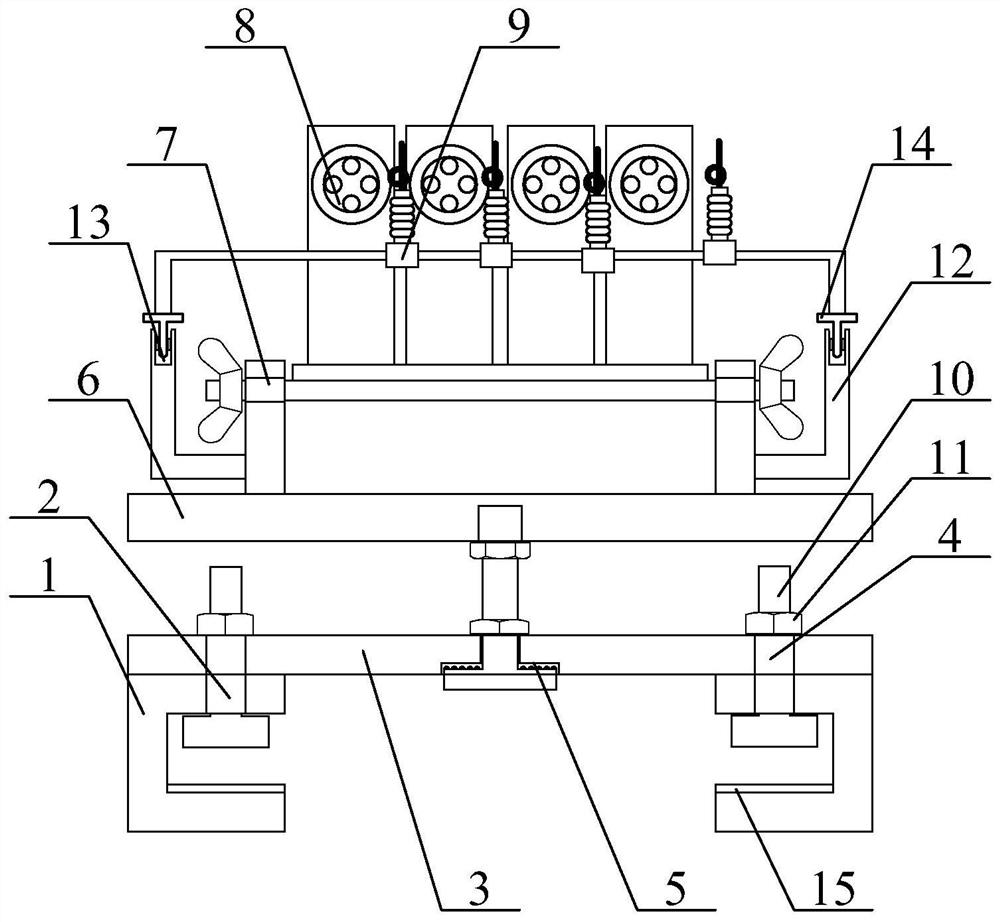

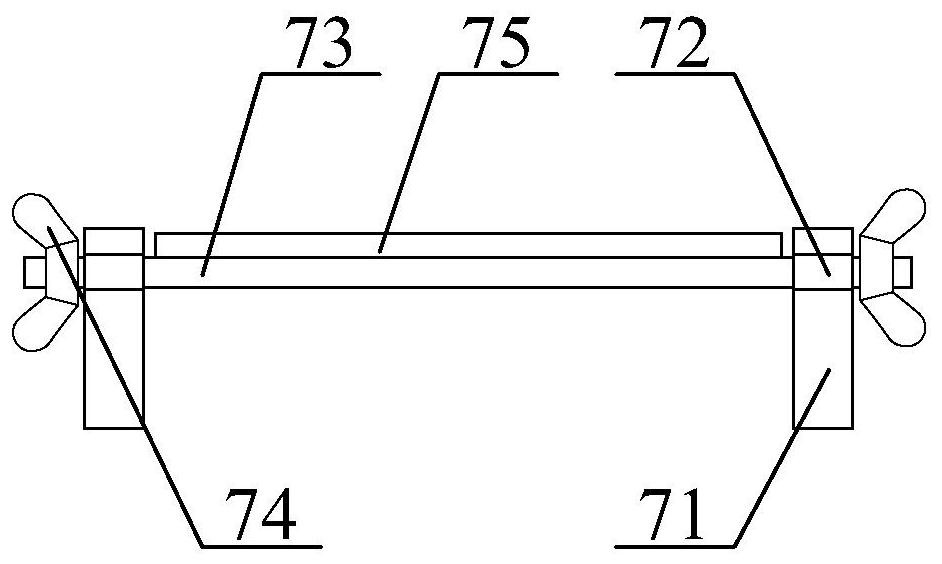

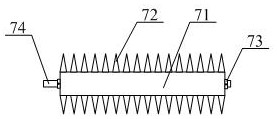

Tension regulating device for textile production

ActiveCN109335798AReasonable designExtended service lifeFilament handlingWebs handlingYarnEngineering

The invention discloses a tension regulating device for textile production. The tension regulating device comprises a regulating frame, a regulating roller set and a stentering assembly; the regulating frame comprises two fixing blocks, first supporting columns and second supporting columns; the regulating roller set comprises a first regulating roller set and a second regulating roller set whichare located at the left and right ends of a regulating rod set correspondingly; and the stentering assembly is located between the first regulating roller set and the second regulating roller set andcomprises a stentering roller and a mounting frame, regulating pressure springs sleeve the two ends of the stentering roller, and the lower ends of the regulating pressure springs are connected with the mounting frame. The tension regulating device is high in practicality and ingenious and reasonable in structural design, the structural size of the tension regulating device can be regulated according to the conveying requirements of different fabrics or yarns, thus the tension regulating device can be applied to conveying of the fabrics or the yarns with the different requirements, the using range of the tension regulating device is expanded, it is ensured that the fabrics or the yarns always keep a tightening state in the conveying process, and the conveying rate of the fabrics or the yarns are increased more conveniently.

Owner:SHENGZHOU WENDA TEXTILE CO LTD

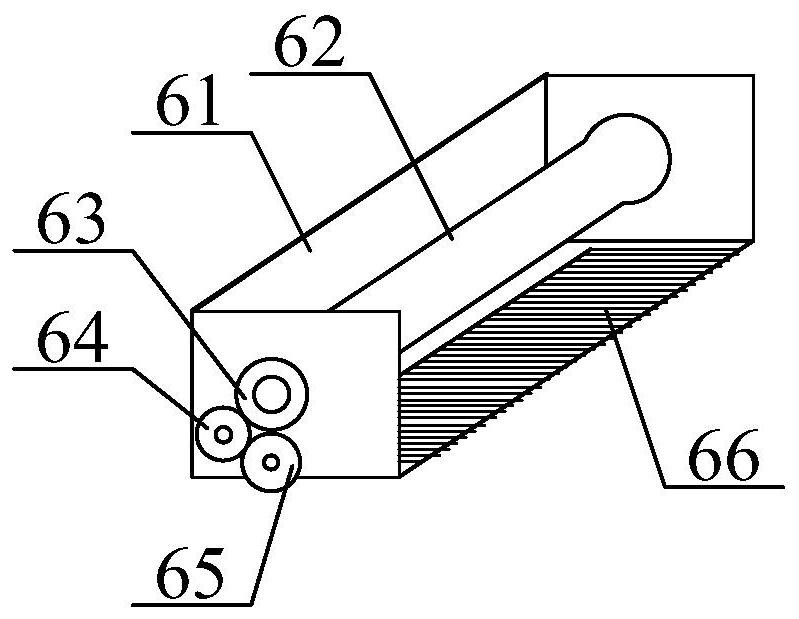

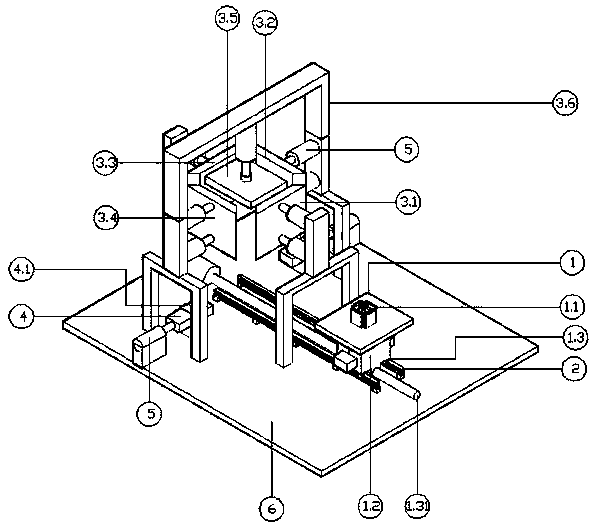

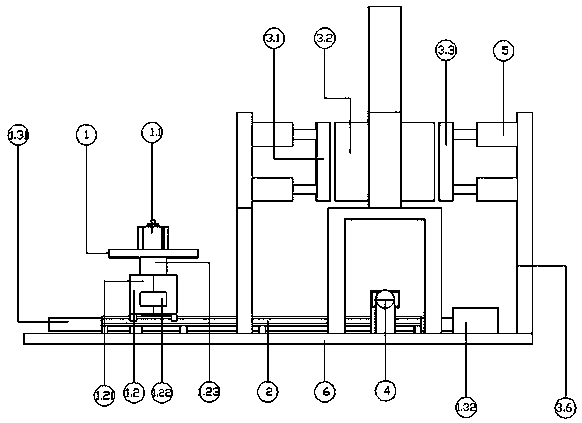

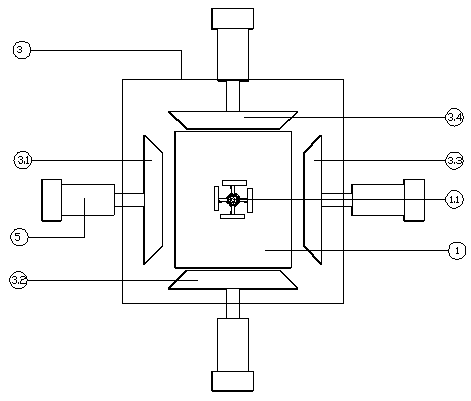

Lithium battery core sorting device and sorting method

ActiveCN108906668AEase of deliveryRealize deliverySortingEngineeringElectrical and Electronics engineering

The invention discloses a sorting method of a lithium battery core sorting device. The method is characterized in that the sorting device comprises a feeding mechanism, a detection mechanism, a material gathering and conversion mechanism and a sorting mechanism, wherein the feeding mechanism comprises the feeding fixing block and a feeding passage; the detection mechanism comprises a detection turntable; a plurality of battery core tubes are uniformly distributed on the detection turntable; each lithium battery core is erected on a conveying belt by the material gathering and conversion mechanism; the sorting mechanism comprises a main sorting passage, two first branch sorting passages and a first pulling plate. The sorting method comprises the following steps that the lithium battery coreis put into a blanking passage; a test disc intermittently rotates, so that the lithium battery core falls into a battery core groove formed in the test disc; an electric test assembly is subjected to electrical parameter test; the tested lithium battery is erected on the conveying belt; the lithium battery core enters the main sorting passage; the first pulling plate rotates; the lithium batterycore enters one first branch sorting passage. The sorting method of the lithium battery core sorting device provided by the invention has the advantages that the automatic sorting of the lithium battery cores is realized; the sorting efficiency is improved.

Owner:萧县鑫辉源电池有限公司

A fully automatic winding shaping device

The invention discloses a winding automatic shaping device. The device includes a pressure-bearing plate, slide rails, and a shaping device, wherein the pressure-bearing plate is a rectangular plate,A locate upright column is fixed on that top of the pressure plate, A slider is arranged below the pressure plate, A slide rail is arranged at the bottom of the slide block and matched with the slideblock, top blocks are respectively arranged on both sides of one end of the slide rail, A lifting device correspond to that top position is arranged between the slide block and the pressure bearing plate, A shaping device is arranged above one end of the slide rail provided with a top block, The shaping device comprises a shaping plate all around, a pressing plate on the top and an air cylinder driving each shaping plate and the pressing plate, wherein each shaping plate is a trapezoidal block and the inclined surfaces of each two trapezoidal blocks are in contact with each other, the pressingplate is a rectangular pressing plate and the threaded cooperation is arranged between the pressing plate and the piston rod of the cylinder; The outer circumference and the upper and lower end facesof the winding can be shaped at one time, so that the step of flipping the winding is omitted. Winding deformation due to excessive extrusion of the shaping plate is prevented.

Owner:常德国力变压器有限公司

High-yield high-stress resistance breeding method for Chinese torreya

InactiveCN108738465AEasy to filterImprove stress resistanceSeed immunisationAgricultural scienceDisinfectant

The invention belongs to the technical field of seed breeding and in particular discloses a high-yield high-stress resistance breeding method for Chinese torreya. The method comprises the following steps: (1) carrying out primary cleaning, namely cleaning picked seeds in clean water, removing stain, and fishing up; (2) draining off the water naturally, namely spreading the seeds after primary cleaning in the step (1) on a mesh screen, and draining off the water naturally; (3) screening the seeds, namely screening seeds which are full and strong in grain by using a seed screening device, and grading the seeds; (4) carrying out sterilization, namely soaking the seeds screened in the step (3) into a disinfectant for 30-60 minutes; (5) drying, namely drying the seeds sterilized in the step (4)at a preheated place for 6-8 hours in the air; (6) collecting, namely naturally cooling the dried seeds naturally, and collecting and putting into bags. The seeds selected according to the scheme areall full in grain and healthy and vigorous, and the yield and the stress resistance of the seeds can be improved through sterilization and drying.

Owner:GUIZHOU WUCHUAN WANNIANFENG AGRI DEV CO LTD

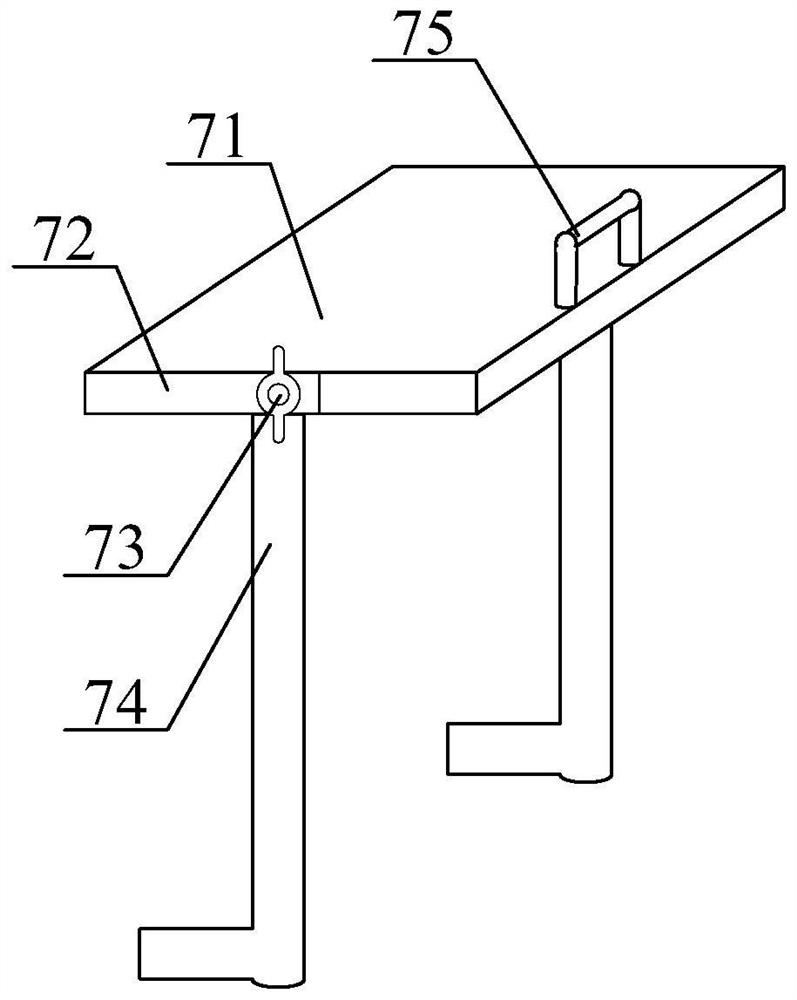

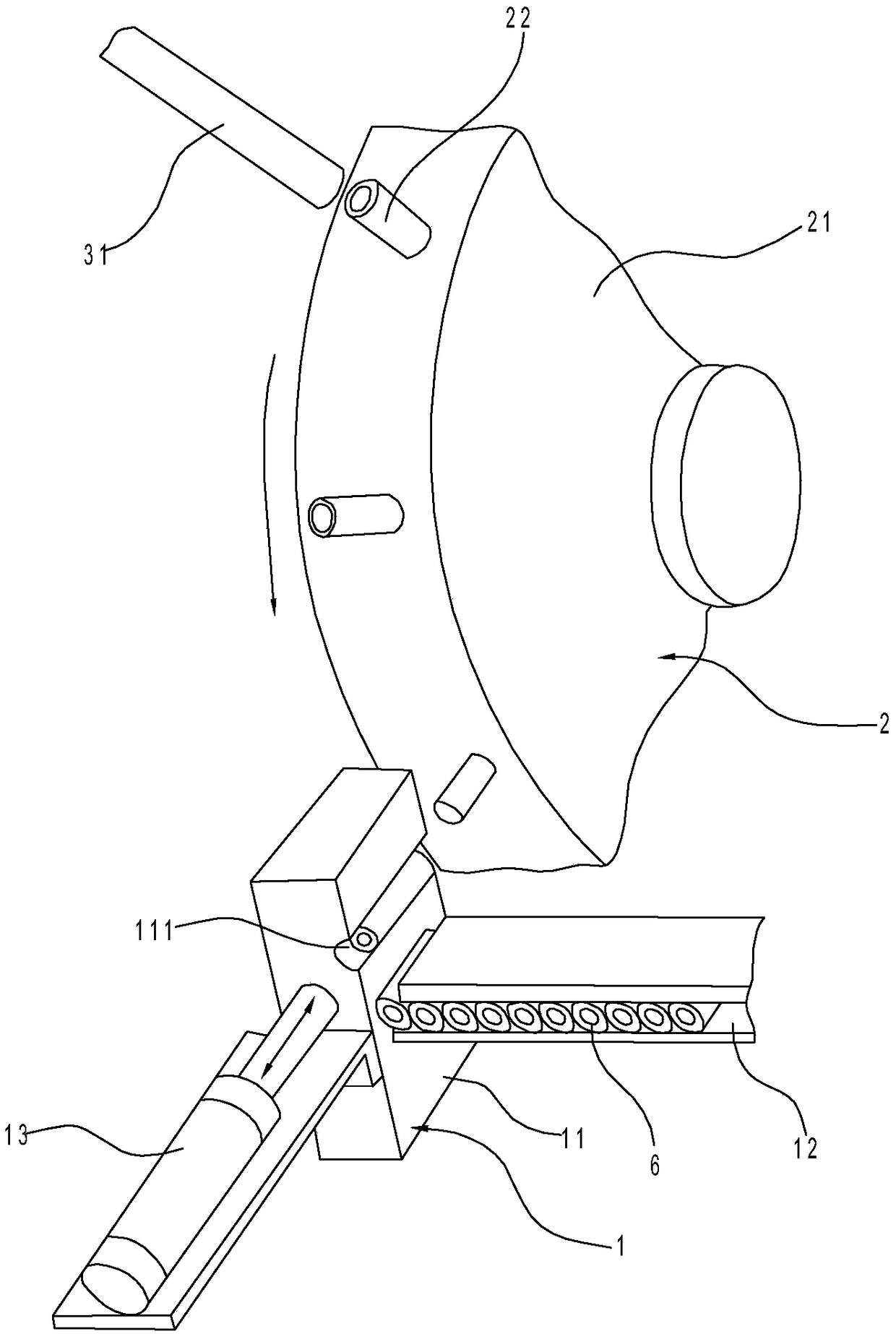

Cutting die lifting vehicle

The invention discloses a cutting die lifting vehicle. The lifting vehicle comprises a lifting mechanism, a cutting die moving mechanism, a cutting die guide mechanism, a bottom plate frame, a bottomplate motor, a rail wheel, an upper cross beam, a chain, a transmission shaft and a chain wheel; the lifting mechanism is arranged at the top of the bottom plate frame, and is fixedly arranged on oneside of the upper cross beam, and the lifting mechanism is composed of a lifting motor, the chain, the transmission shaft and the chain wheel; the cutting die moving mechanism is composed of a cuttingdie plate, a drag hook moving motor, a drag hook air cylinder, a cutting die pulling support, a drag hook, a synchronous belt and a synchronous belt wheel; and the cutting die guide mechanism is composed of a micro motor, a steering air cylinder and a cutting die conveying wheel. According to the cutting die lifting vehicle, a cutting die is lifted through the lifting mechanism, the structure iscompact, and the operation is convenient; the cutting die moving mechanism is stable in operation, the moving process is smooth, and the cutting die is convenient to move; the cutting die guide mechanism steers the cutting die, and conveying in different directions is facilitated; and the chain transmission and the belt transmission are adopted on the whole, the operation is stable, and the energyloss is small.

Owner:YANCHENG HUASEN MACHINERY

Dimming system and method based on pedestrian volume and position information

PendingCN112533141AEffective useEasy to useEnergy saving control techniquesLocation information based serviceEarth surfaceRemote sensing

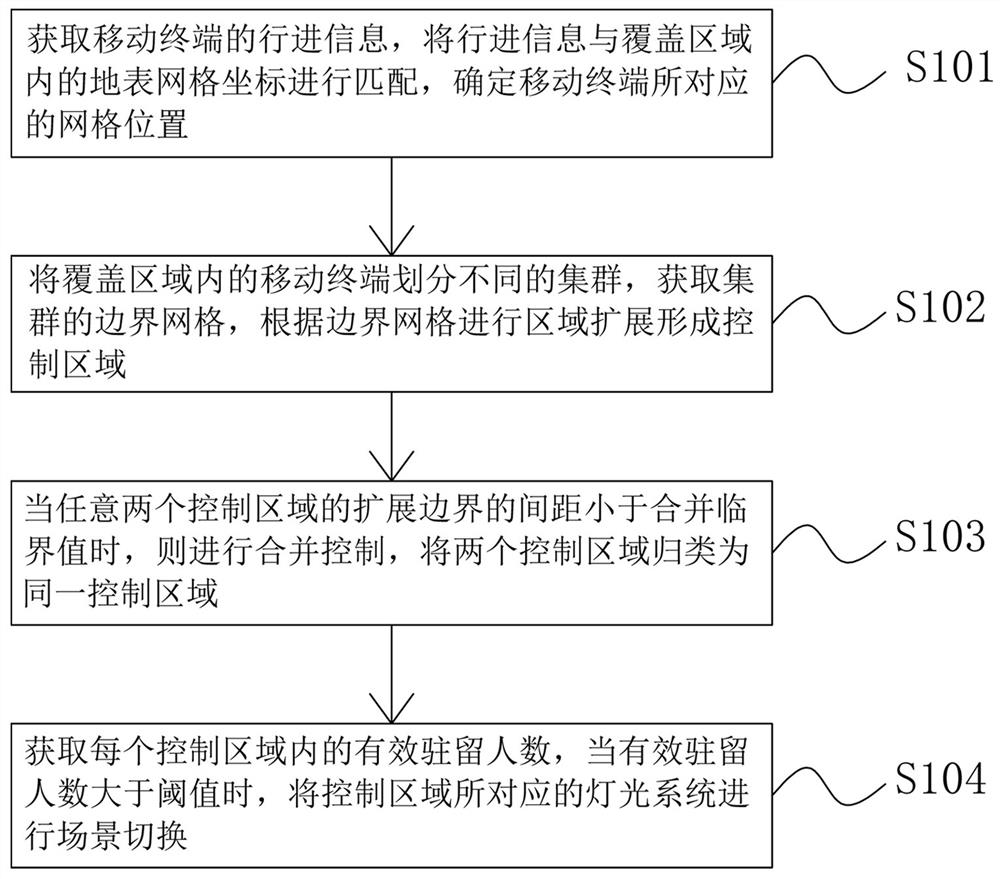

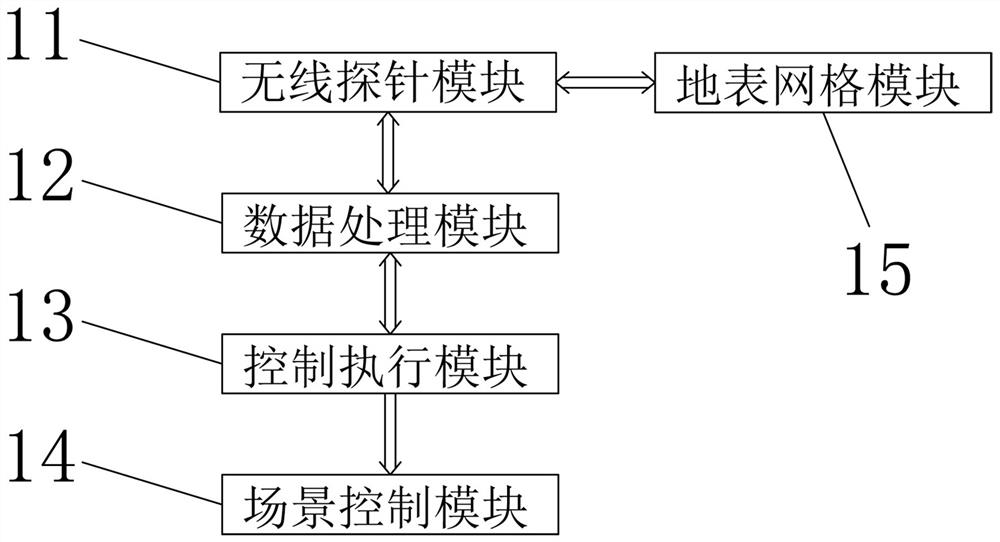

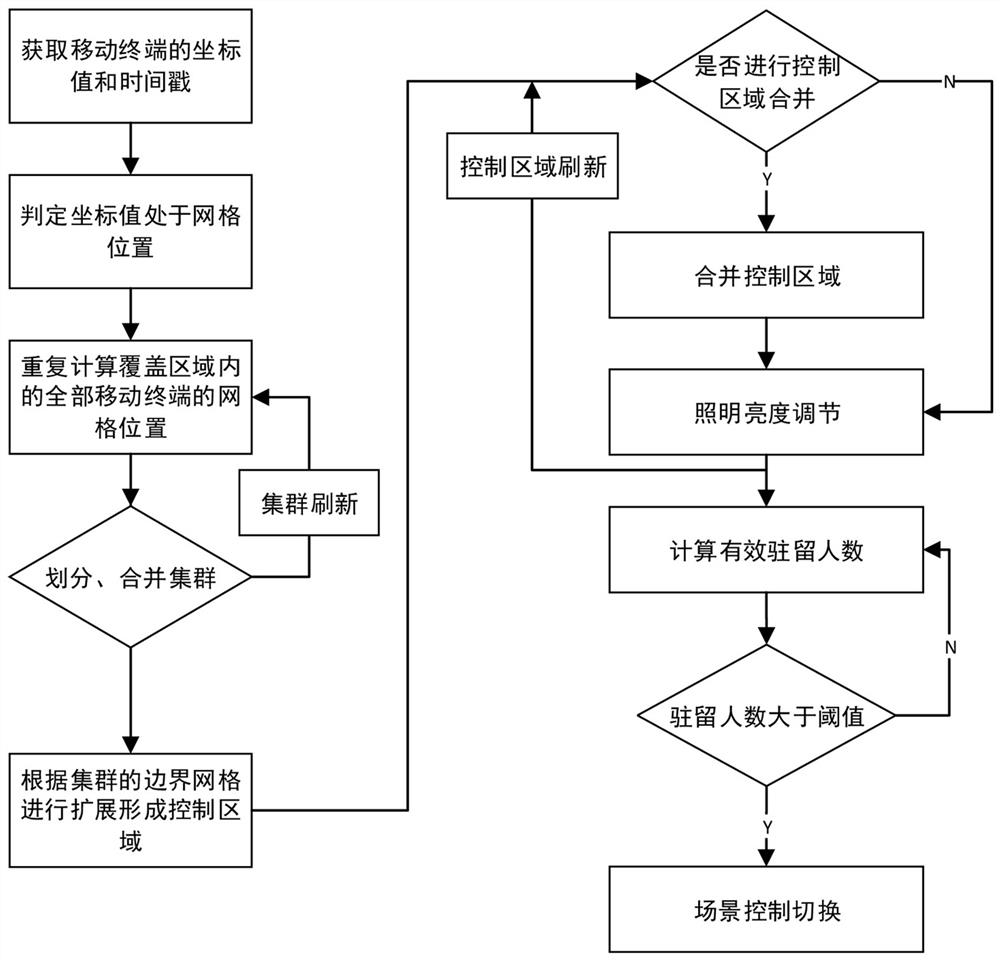

The invention discloses a dimming system and method based on pedestrian volume and position information, and the method comprises the steps: obtaining the advancing information of a mobile terminal, enabling the advancing information to be matched with the coordinates of an earth surface grid in a coverage region, and determining the position of the grid corresponding to the mobile terminal; dividing the mobile terminals in the coverage area into different clusters, obtaining boundary grids of the clusters, and performing area expansion according to the boundary grids to form a control area; when the distance between the extended boundaries of any two control areas is smaller than a merging critical value, merging control is carried out, and the two control areas are classified into the same control area; obtaining the effective resident number of people in each control area, and when the effective resident number of people is greater than a threshold, performing scene switching on thelighting system corresponding to the control area. According to the invention, the position data of the mobile terminal in the coverage area is detected through the wireless probe, real-time dimmingand scene control are carried out according to the position distribution of people, and corresponding light scene switching is triggered through the effective resident number of people.

Owner:ZHEJIANG JINGRI LIGHTING TECH

Inspection device special for animal husbandry and veterinary

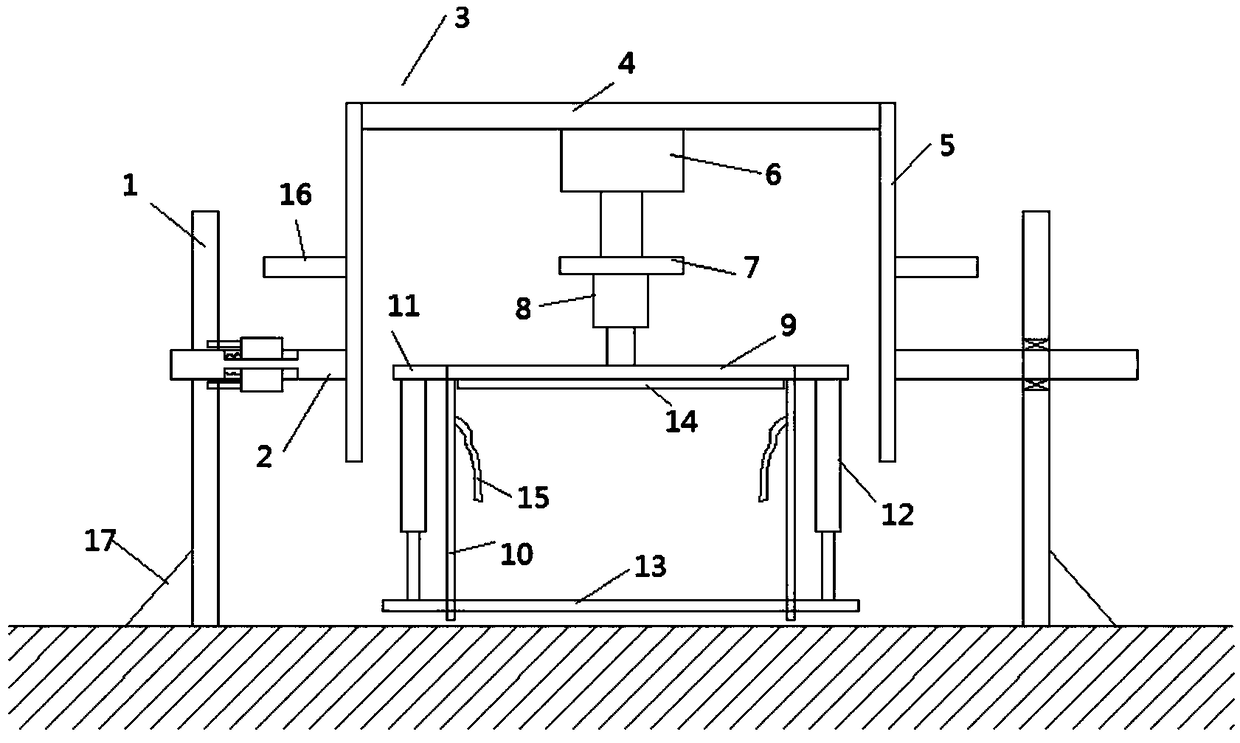

The invention relates to an inspection device special for animal husbandry and veterinary. The inspection device special for animal husbandry and veterinary comprises two supporting plates, the supporting plates are fixedly connected on the ground, and a top frame is rotationally connected between the two supporting plates through a rotating shaft and is composed of a connecting plate and verticalplates fixedly connected on the two sides of the connecting plate; a motor is fixedly connected on the lower side of the connecting plate, a first installing plate is fixedly connected to an output shaft on the lower side of the motor, a first air cylinder is fixedly connected on the lower side of the first installing plate, a first placing plate is fixedly connected to the end of a first pistonrod on the lower side of the first air cylinder, and the left side, the right side and the front side of the lower surface of the first placing plate are each provided with a vertical rod at equal intervals; second installing plates are fixedly connected to the left end and the right end of the first placing plate, second air cylinders are fixedly connected on the lower sides of the second installing plates, a second placing plate is fixedly connected to the ends of second piston rods on the lower sides of the second air cylinders, multiple through grooves are formed in the second placing plate, and are matched with the vertical rods, and the second placing plate is slidingly connected in the length direction of the vertical rods. The inspection device special for animal husbandry and veterinary is simple in structure, convenient to operate and suitable for application and popularization.

Owner:王凤璐

Multifunctional label paper collecting device

InactiveCN106629167ALess prone to positional deviationEasy to see the conveying situationWebs handlingPulp and paper industryConveyor belt

The invention discloses a multifunctional label paper collecting device, which comprises a device body, a collecting coil and an electromotor. The collecting coil is arranged on the right upper end of the device body, the electromotor drives the collecting coil to rotate, the middle of the upper end surface of the device body is provided with a conveyor belt mounting cavity, a conveyor belt is arranged in the conveyor belt mounting cavity, a front positioning baffle plate is arranged at the front end of the conveyor belt mounting cavity, a rear positioning baffle plate is arranged at the rear end of the conveyor belt mounting cavity, and the front positioning baffle plate and the rear positioning baffle plate are symmetrically arranged; the back positioning baffle plate is provided with a lamp holder, the lamp holder is provided with an LED lighting lamp and a button switch used to control ON / OFF of the LED lighting lamp, a support frame is arranged on two guide rails, a cylinder is arranged at the front end surface of the support frame, the cylinder is connected to the support frame by a piston rod, and the cylinder drives the support frame to move front and back along the two guide rails through the piston rod. According to the technical solution above, the structural design is reasonable, the structure is simple, multiple functions are realized, label paper is not easily deviated in a conveying process, and use is convenient.

Owner:嘉兴市耀华精密金属股份有限公司

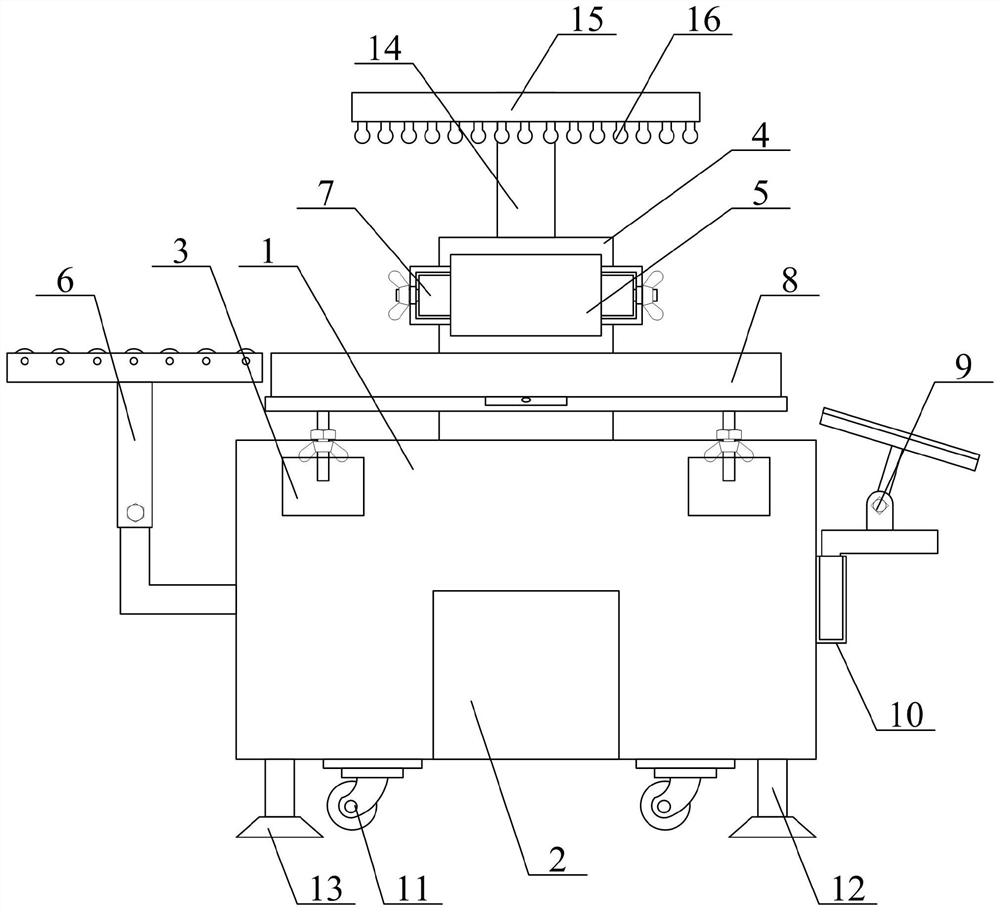

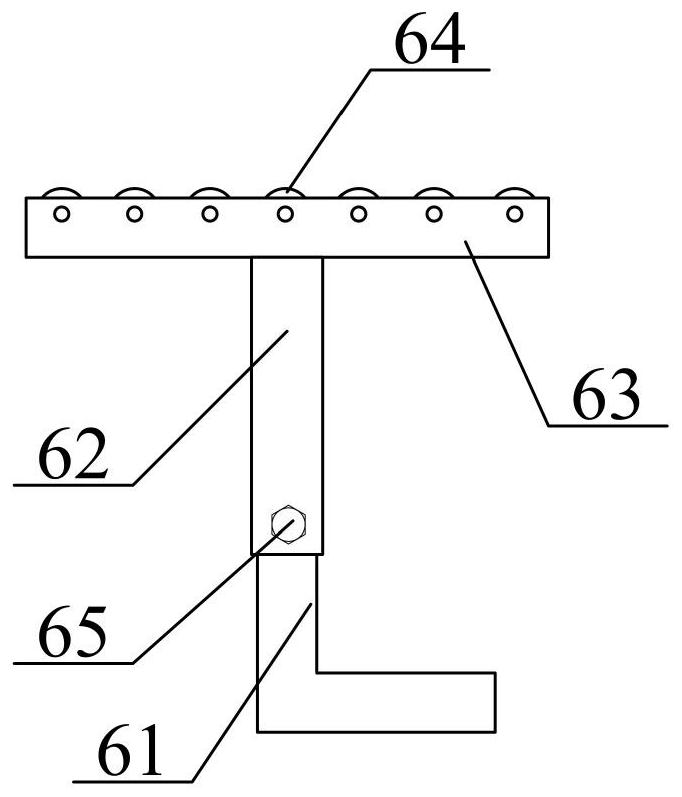

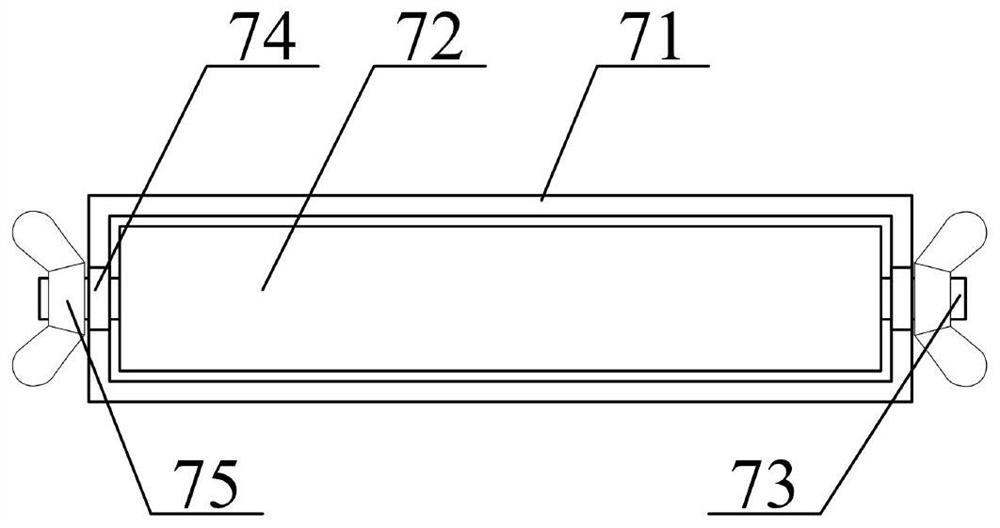

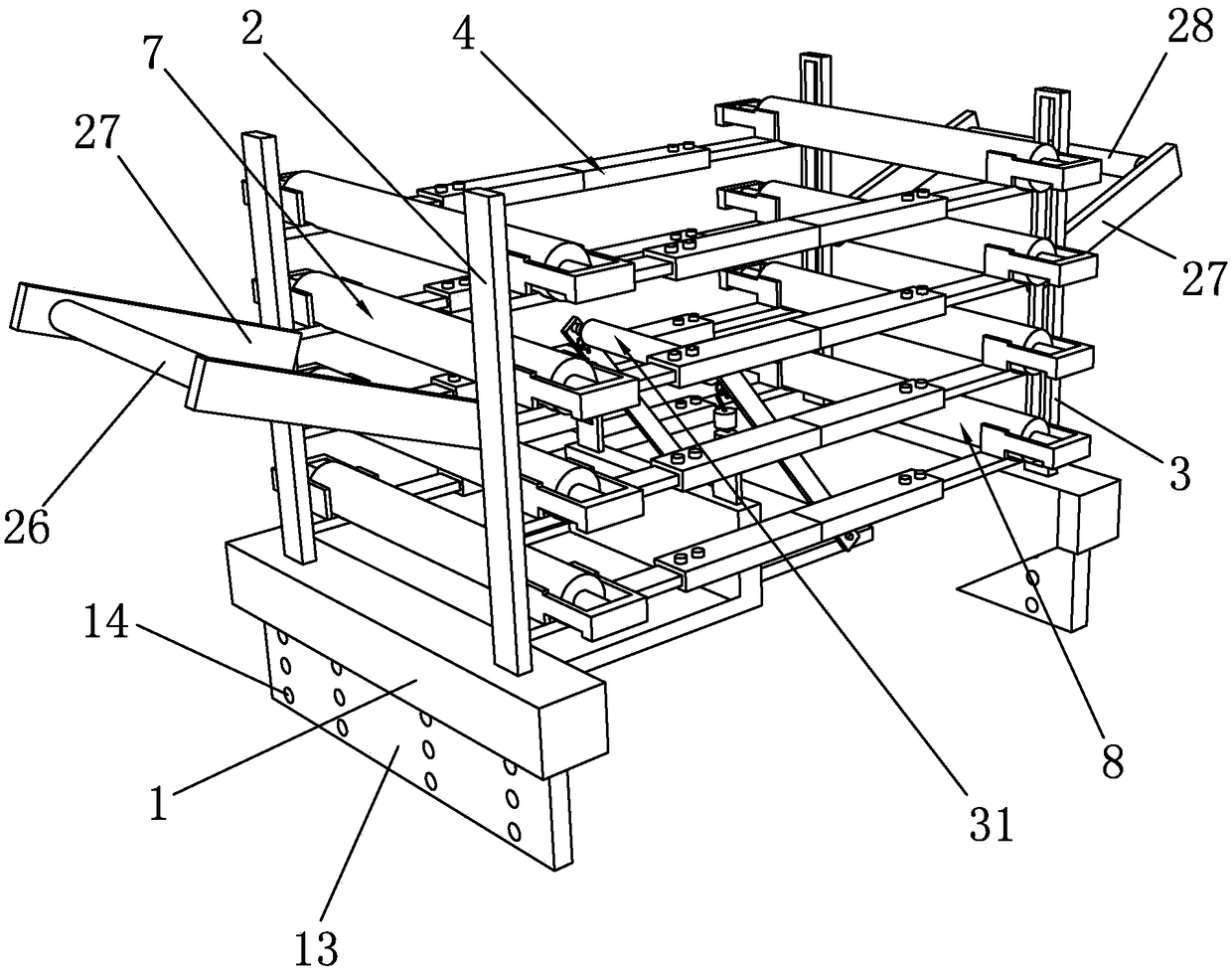

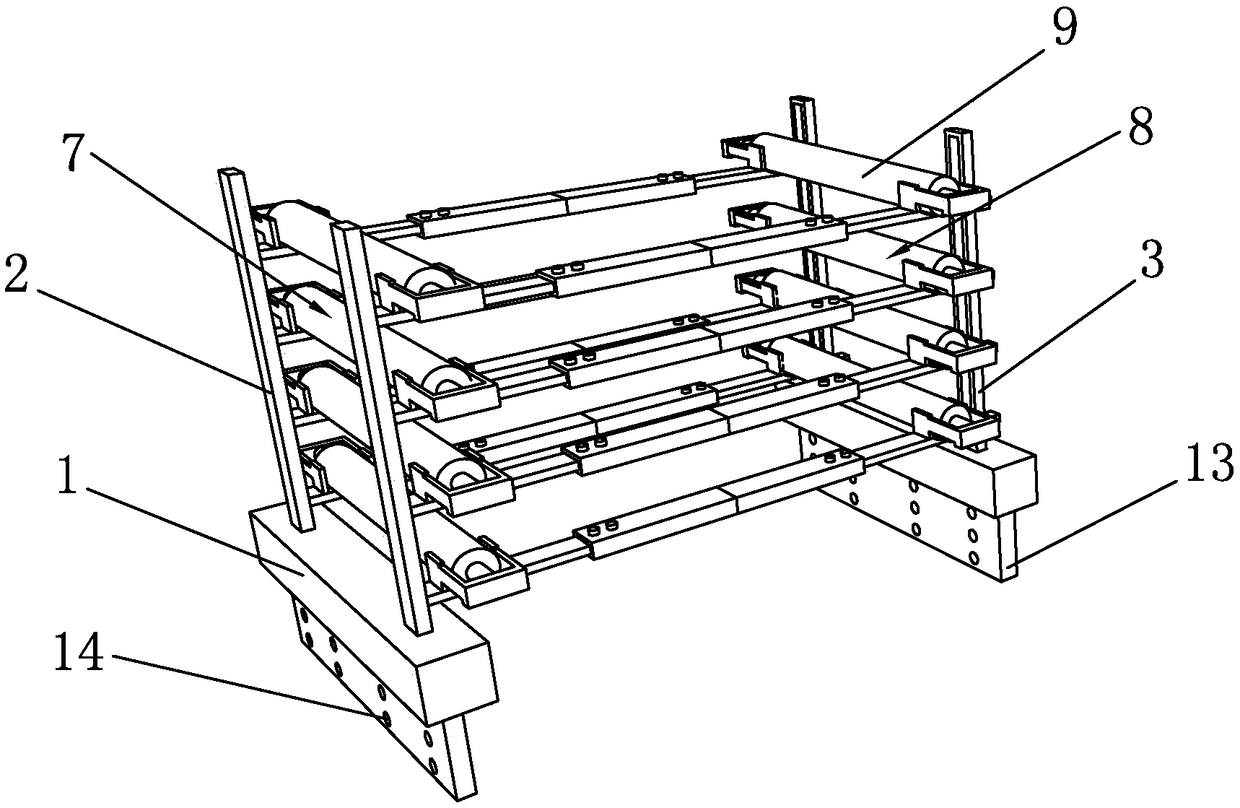

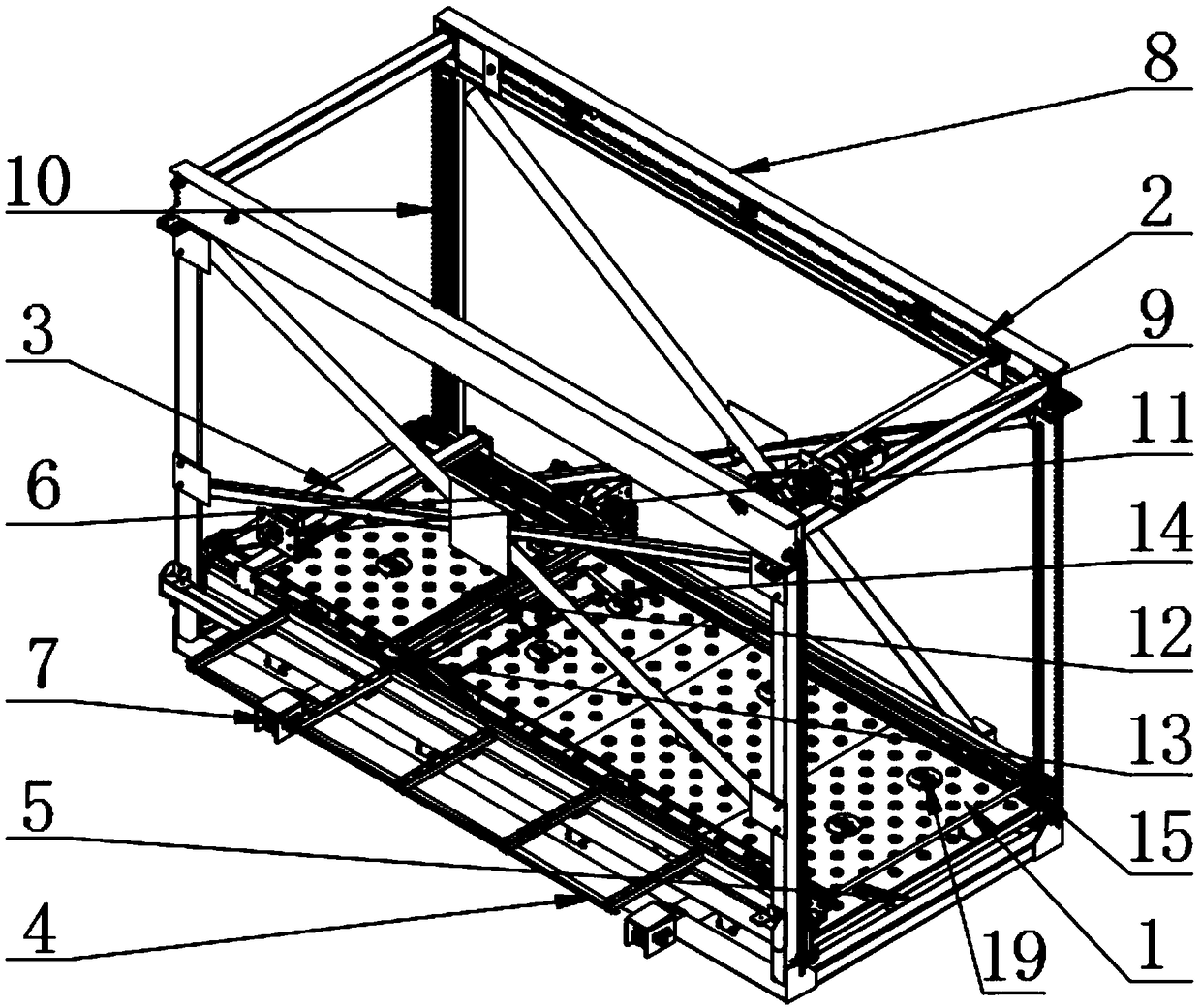

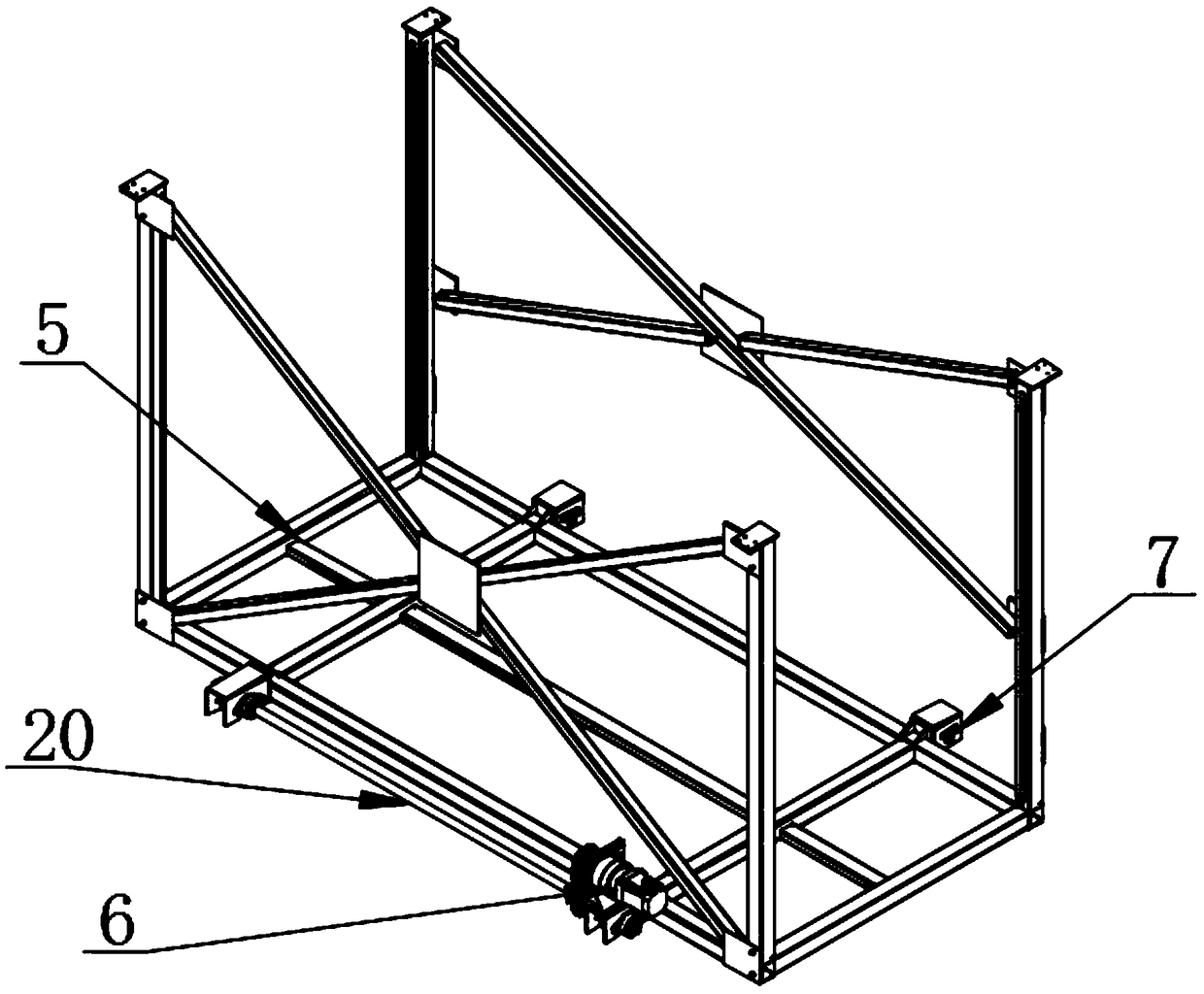

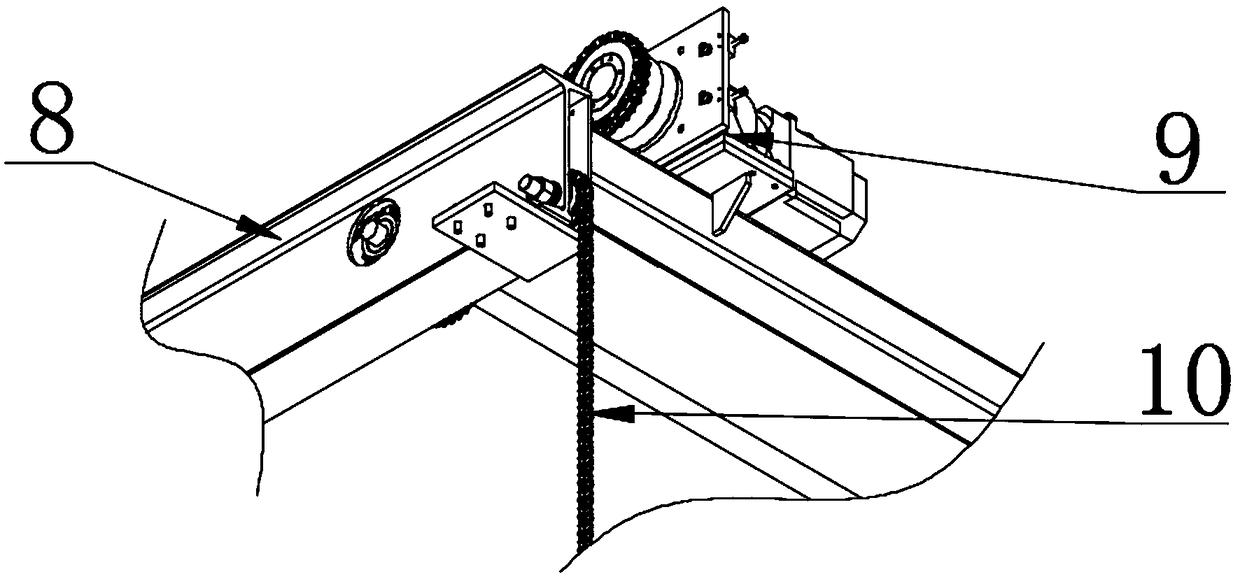

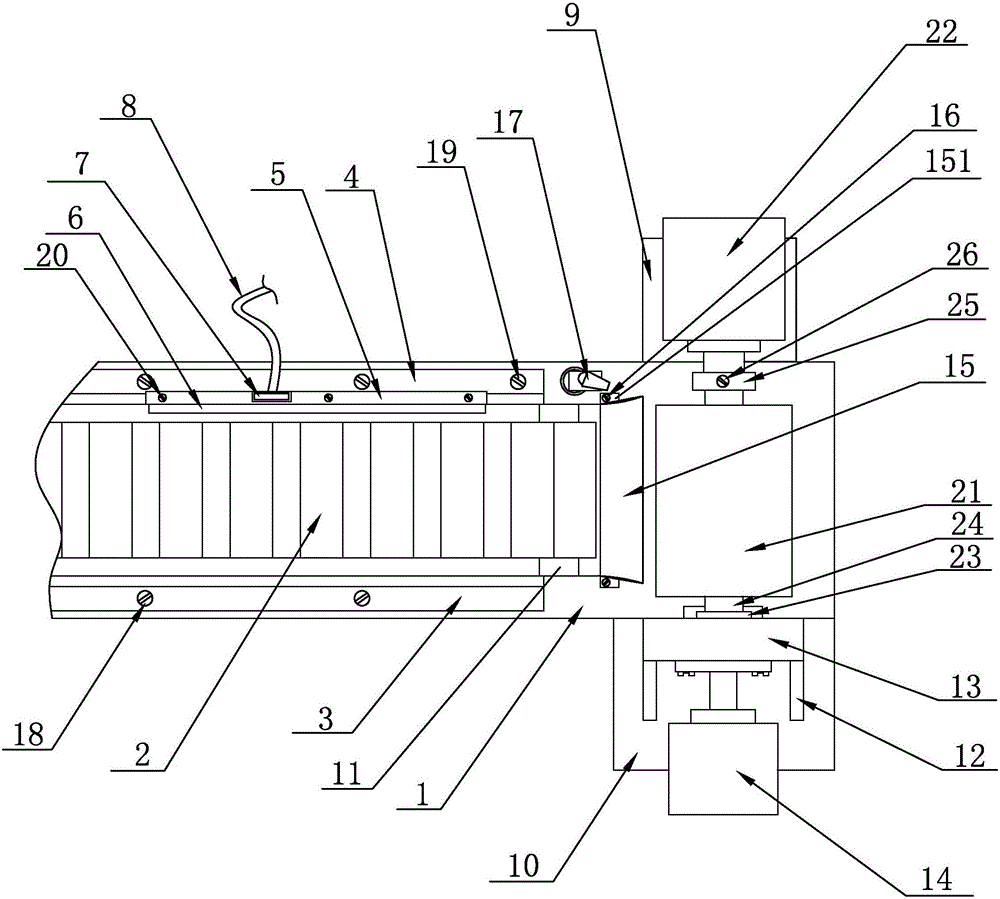

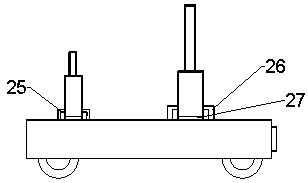

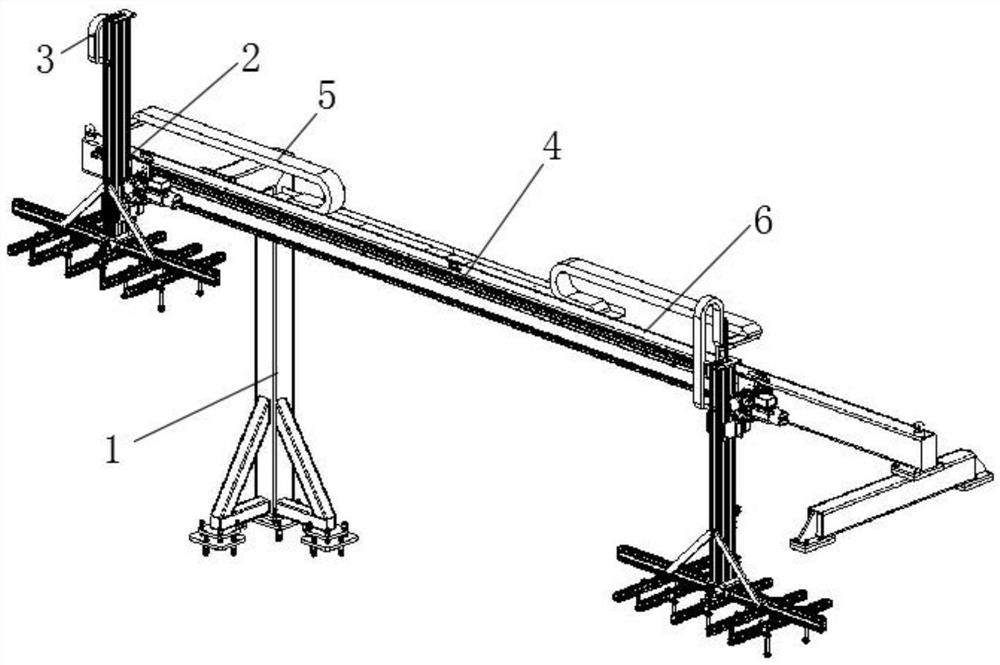

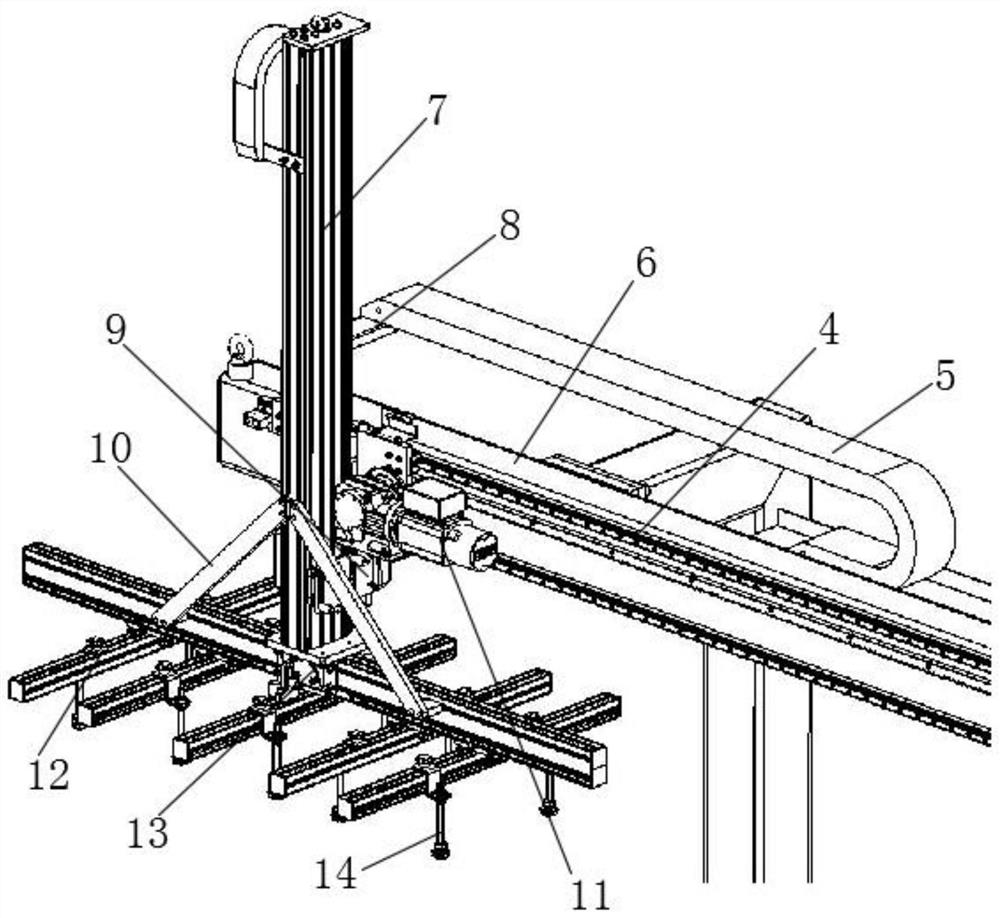

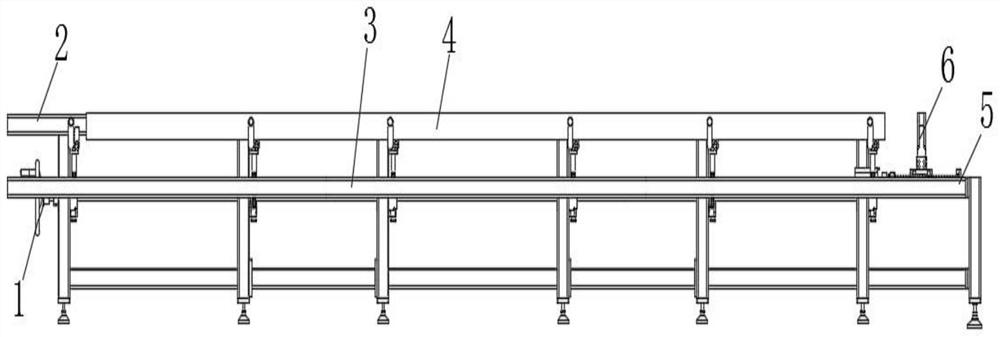

Synchronous lifting and moving type feeding equipment of engineering machinery

InactiveCN110562698AEase of deliveryEasy to observe the transportation situationPackagingSupporting framesEngineeringReducer

The invention relates to synchronous lifting and moving type feeding equipment of engineering machinery. The synchronous lifting and moving type feeding equipment of the engineering machinery comprises a body frame, a lifting system, a feeding device and a kinetic energy system device, a low lift and a high lift are arranged on the two sides of the surface of the body frame, the top of the low lift is connected with the lower surface of the feeding device, the top of the high lift is connected with the upper surface of the feeding device, wherein the feeding device comprises feeding machine equipment, a feeding shell protection layer, a discharging detector and a bearing, the feeding machine equipment is arranged in the middle of the feeding device, the top end of a rolling shaft of the feeding machine equipment is provided with a flanged threaded flange, the upper surface of the feeding machine equipment is provided with a feeding port, the bottom of the feeding machine equipment is provided with a discharging port, the inner surface of the bottom of the feeding machine equipment is internally embedded with the discharging detector, the feeding machine equipment is connected witha speed reducer through the bearing, the speed reducer is connected with a motor through the rolling shaft, and rollers are arranged at the bottom of the body frame. According to the synchronous lifting and moving type feeding equipment, a lifting system is flexibly applied, and the use of the detector is effectively prepared for subsequent material conveying.

Owner:徐州贝峰机械制造有限公司

Duplex mechanical hand for refrigerator inner container punching and cutting system

PendingCN112777308ALimit lift heightInhibit sheddingMetal working apparatusConveyor partsRobot handIcebox

The invention discloses a duplex mechanical hand for a refrigerator inner container punching and cutting system. The mechanical hand comprises a supporting column and a transverse moving frame. The supporting column is fixedly arranged at one end of the bottom of the transverse moving frame. The output end of a transverse moving motor drives a transverse moving main gear to rotate, the transverse moving main gear is connected with a transverse moving rack in an engaged manner, thus a transverse moving plate moves on a transverse moving slide rail, then moving of conveying mechanical hands is achieved, when one plate is conveyed to the middle position of the transverse moving frame, the plate is put down, the conveying mechanical hand is controlled to return to the initial position, then the other conveying mechanical hand is controlled to transport the plate, and the two conveying mechanical hands cooperate with each other. The problems that one conveying mechanical hand is used for transporting traditionally, as a result, the transfer period is long, and the conveying efficiency is low are solved, and the conveying effect is achieved conveniently.

Owner:江苏天辰智能装备有限公司 +1

A high-speed stranding machine for preventing wire breakage

ActiveCN113450971BEasy to handleEasy to adjustCable/conductor manufactureCopper wireElectric machine

The invention discloses an anti-breakage high-speed twisting machine, which comprises a base, a motherboard is fixedly connected above the inner right end of the base, and a daughter board is connected through the inside of the mother board, and the lower left side of the daughter board is connected There is a first runner, and the inside of the first runner is connected with a first rotating rod; the movable box is fixedly connected to the upper end position of the left side of the sub-board, and the upper left side of the inner part of the movable box passes through the output shaft of the right end of the motor An installation block is connected, and a first electric telescopic rod is fixedly connected to the upper and lower end of the right side of the installation block, a first movable plate is fixedly connected to the lower end of the first electric telescopic rod, and the lower end of the first movable plate is closely connected There is a second movable plate; a fixed block is movably connected to the right end position of the second movable plate through a cross bar. The anti-breakage high-speed stranding machine is not only convenient for the anti-breakage treatment of the twisted copper wire, but also convenient for adjusting the position of the twisted copper wire, and convenient for disassembling and assembling the copper coil.

Owner:DONGGUAN NEW ENSHIANG MACHINERY ENTERPRISE

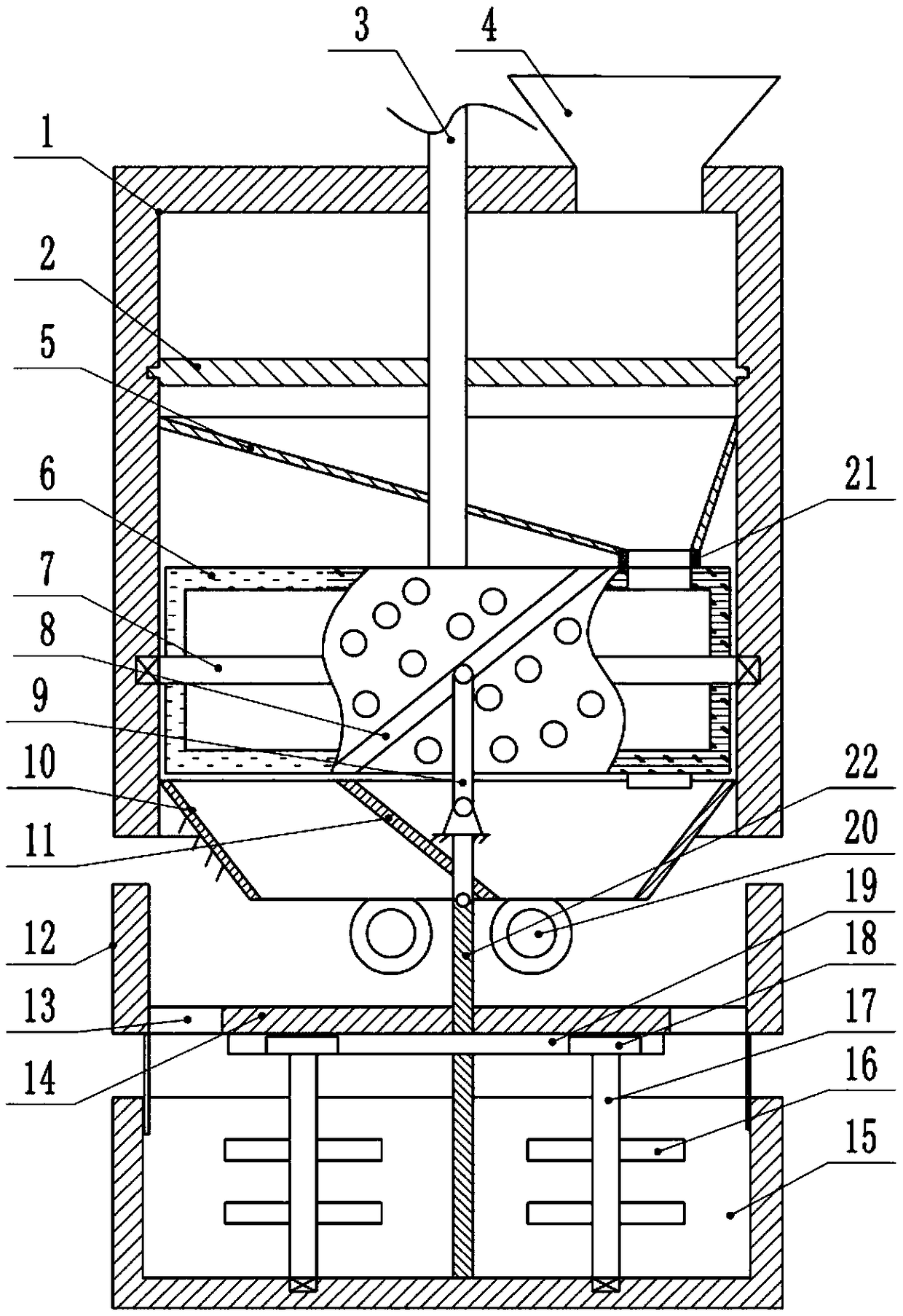

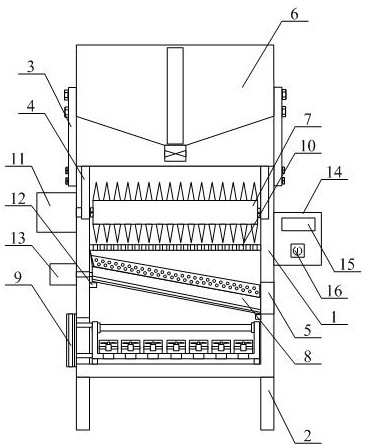

Concentrated feed processing and screening device

The invention provides a concentrated feed processing and screening device, including a base, a directional wheel, a universal wheel, a support rod, an outer barrel, an inner barrel structure that can be graded and screened, a fixed adsorption cleaning seat structure, an adjustable and dredging upper hopper structure, and can be plugged, separated, and fixed. Seat structure, barrel cover, feeding hole, cleaning hole, support block, vacuum cleaner assembly, dust removal connecting pipe, connecting hose and discharge hole, the directional wheels are respectively bolted to the left side of the lower end of the base; The wheels are respectively bolted to the lower right side of the base. The arrangement of the upper hopper, the first socket slot, the L-shaped socket plate, the sliding frame, the wing nut and the T-shaped dredging pipe in the present invention is beneficial to the rotation of the wing nut to move during use, and then to grasp the T-shaped The upper end of the dredging pipe moves up and down, and then the lower end of the T-shaped dredging pipe is used to dredge the inside of the feeding connecting pipe to prevent blockage during work.

Owner:利津天普阳光饲料有限公司

Intelligent petroleum coke production equipment

ActiveCN110976021AImprove drying effectAdd observation functionDrying gas arrangementsGrain treatmentsElectric machineryProcess engineering

The invention provides intelligent petroleum coke production equipment. The intelligent petroleum coke production equipment comprises a production tank, supporting rods, connecting plates, sliding plug-in grooves, a discharging hole, an adjustable observation feeding box structure, a detachably maintainable crushing roller structure, a ventilated conveying rack structure, a maintainable heating drying box structure, a hollowed-out plate, a crushing motor, a supporting block, a vibration motor, a control box, a PLC and a power switch, wherein the upper ends of the supporting rods are respectively welded at four corners of the lower end of the production tank. Due to the arrangement of the PLC, the power switch, the crushing motor, the vibration motor, a feeding pipe and an electromagnetic valve, electric equipment can be controlled to work through the PLC in the working process, and intelligent production work can be conveniently realized; and due to the arrangement of a crushing roller, crushing blades, a fixing pipe, a first connecting rod, the production tank and the sliding plug-in grooves, the crushing roller and the crushing blades can be conveniently disassembled in the working process, and the crushing blades can be conveniently maintained and replaced.

Owner:DONGYING LIANHE PETROCHEMICAL CO LTD

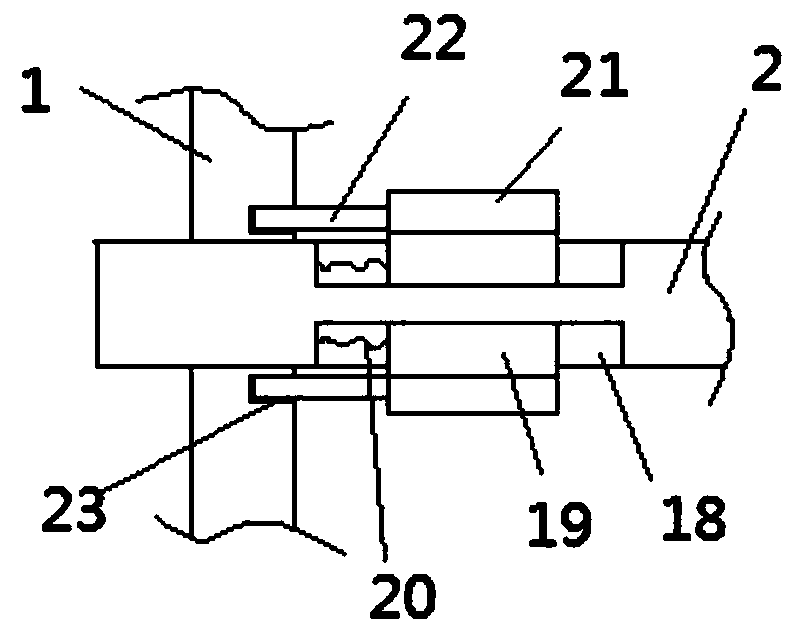

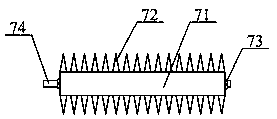

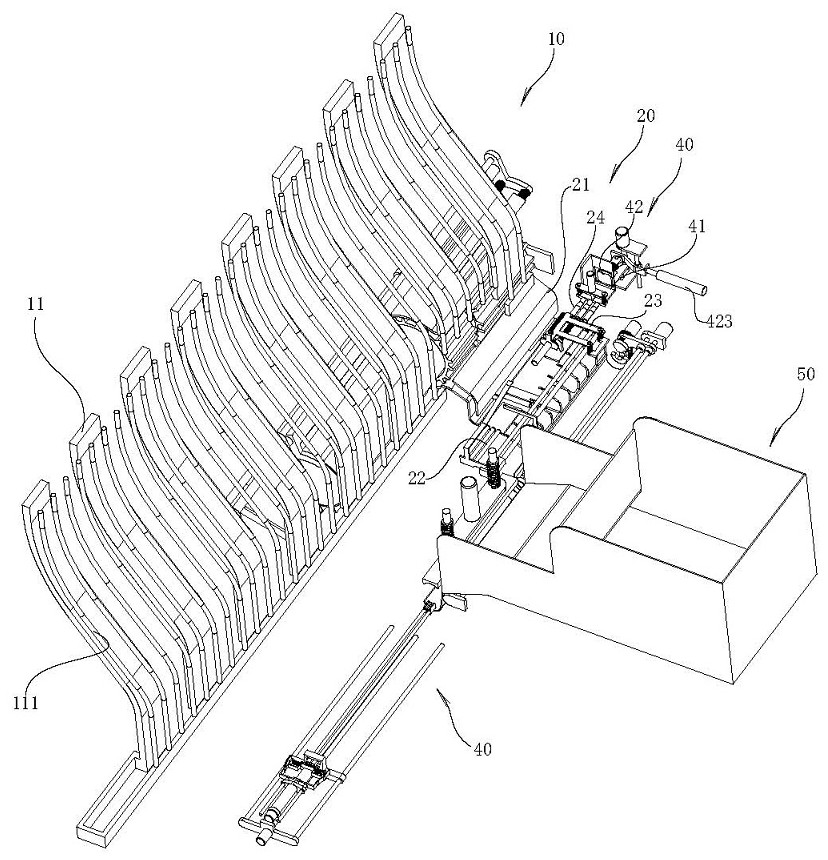

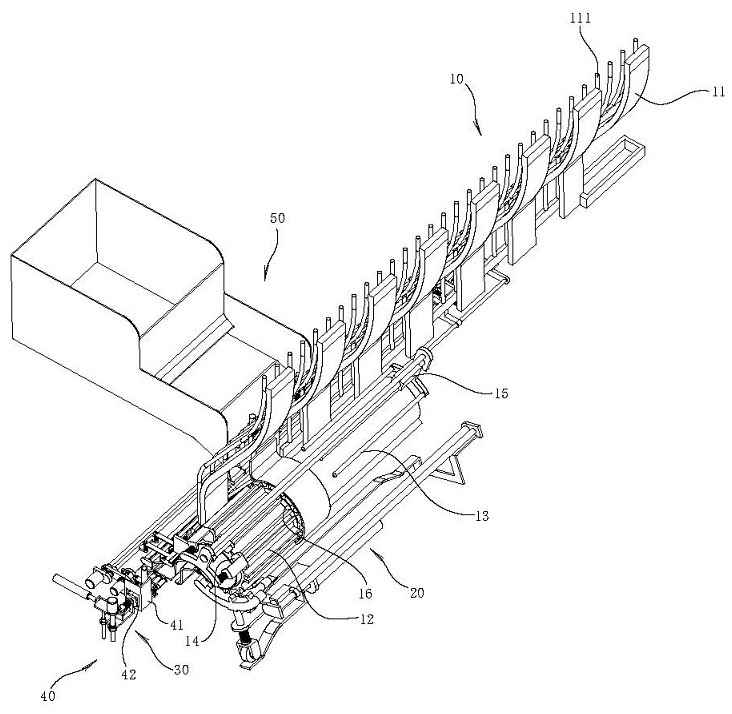

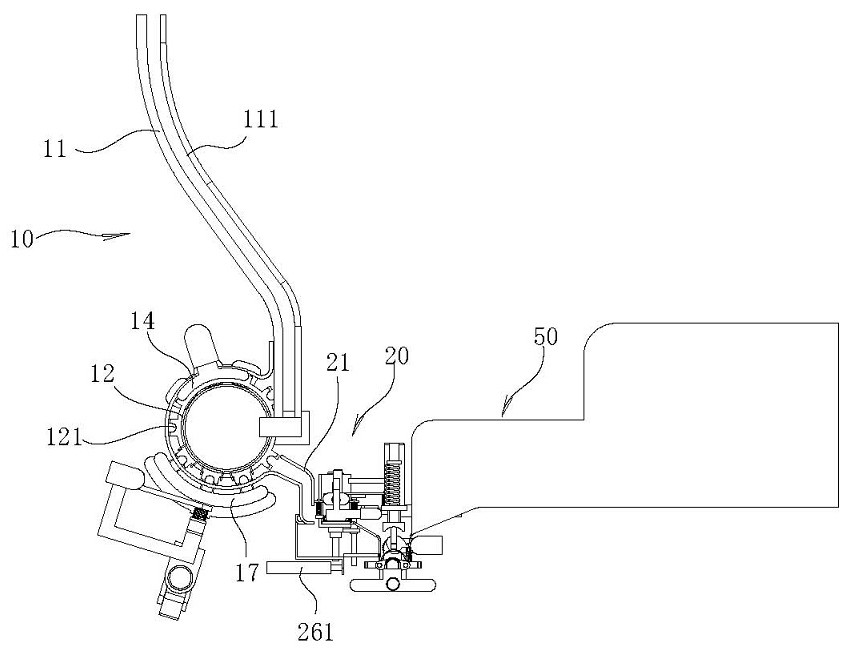

Wire harness leading-out device

ActiveCN111884012AAvoid entanglementEase of deliveryContact member assembly/disassemblyStructural engineeringMechanical engineering

Owner:YJH ELECTRICAL EQUIP

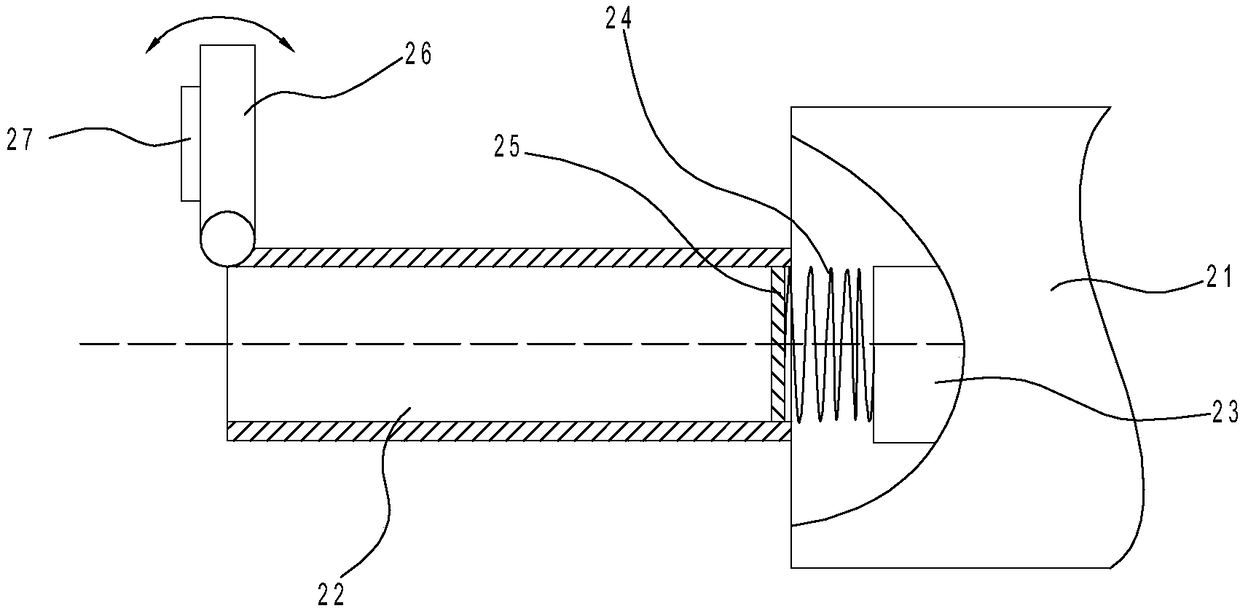

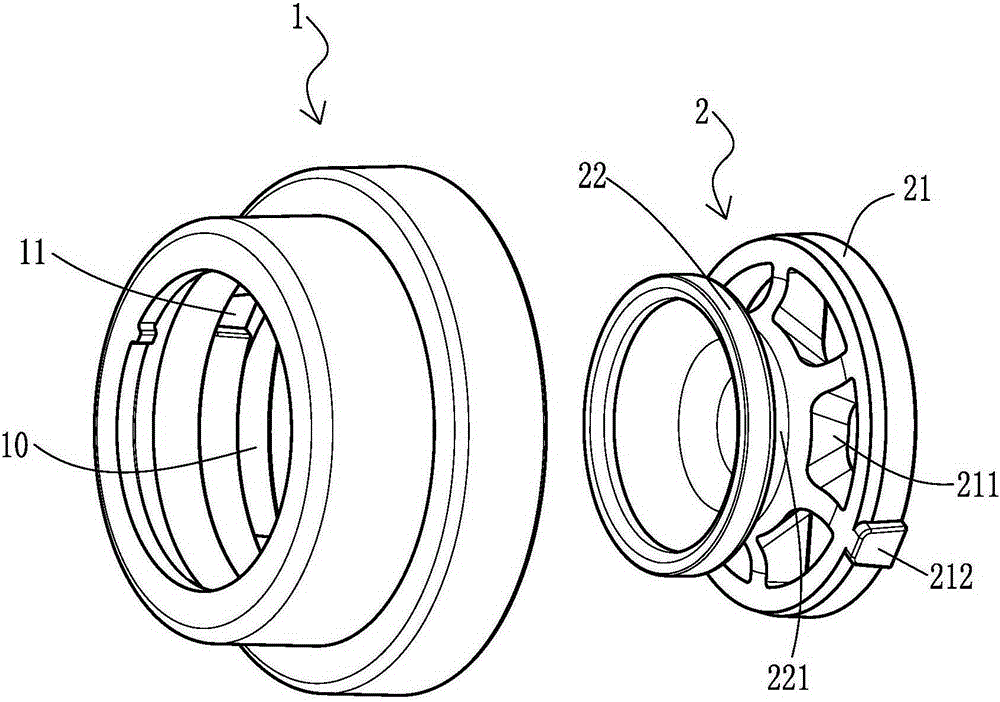

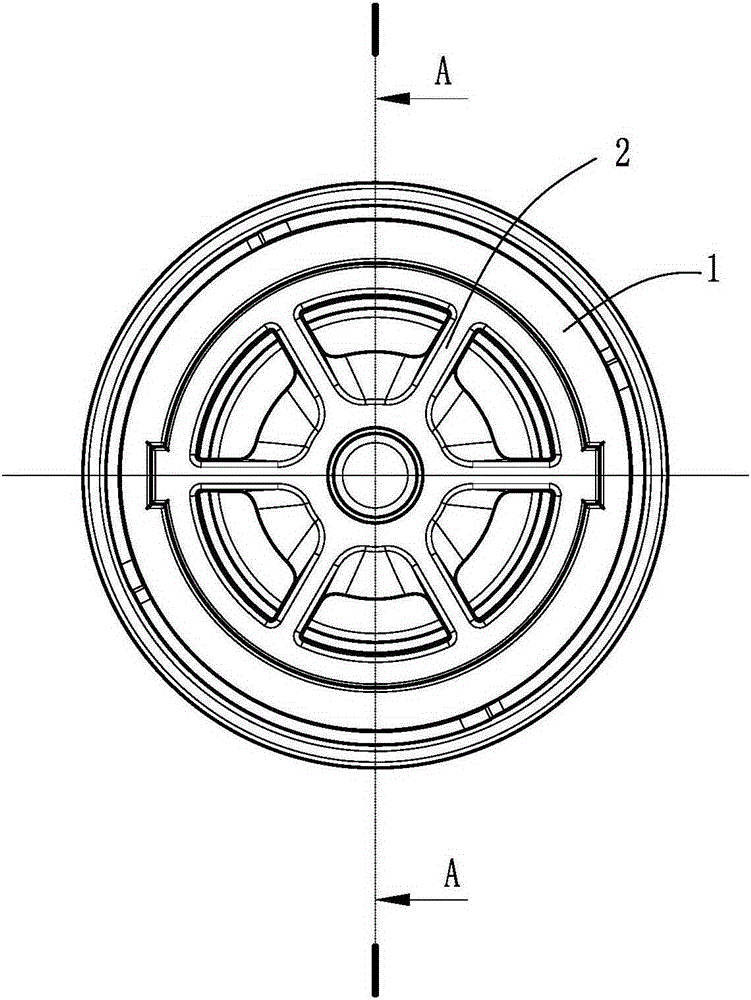

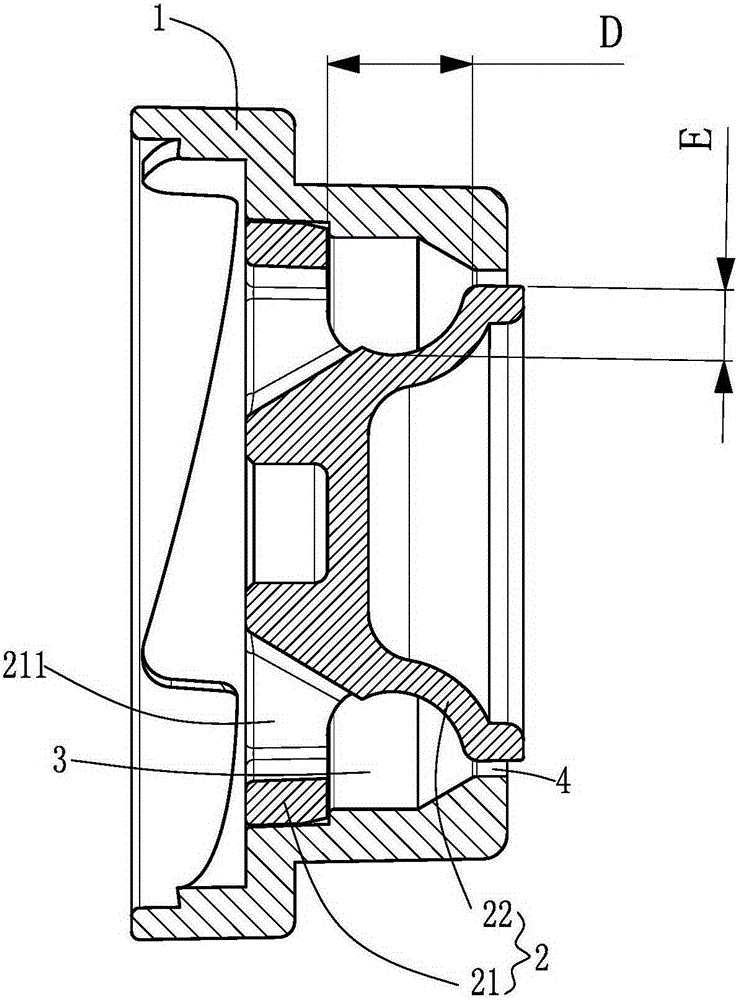

Wrapper die head and food processor comprising wrapper die head

InactiveCN105248509AAvoid breakingAvoid crackingDough extruding machinesMechanical engineeringEngineering

The invention relates to a wrapper die head and a food processor comprising the wrapper die head. The wrapper die head comprises an outer shell arranged on the food processer, wherein a cavity is formed in the shell; an inner core is arranged in the cavity and comprises a mounting part and an extending part; a plurality of dough passages are arranged on the mounting part; an arc groove is formed in the extending part; the arc groove and the inner wall of the shell form a dough extruding cavity which is communicated with the dough passages; an extruding outlet which is communicated with the dough extruding cavity is formed between the extending part and the shell. The extruding space of the wrapper die head is large, so that when a dough passes through the extruding space, an enough extruding force is obtained, the dough is uniformly stressed in the extruding space and is compacted together, and after wrappers are extruded from the extruding outlet, impressions are not caused, and the wrappers are not easy to break; when the wrappers are cooked in water, the wrappers are not easy to break and are better in mouthfeel. The wrappers prepared by the food processor comprising the wrapper die head are higher in quality.

Owner:刘魁

Thread jumping prevention device for textile processing

ActiveCN112279003AEasy buffering workAvoid disconnectionFilament handlingWoven fabricTextile processing

The invention provides a thread jumping prevention device for textile processing. The thread jumping prevention device comprises fixing seats, connecting holes, a first connecting plate, fixing holes,an inserting groove, a rotatable locking supporting plate structure, an adjustable supporting fixing plate structure, a protective tensioning guide pipe structure, a drawable buffering guide hook structure, an inverted T-shaped threaded rod, a square-head nut, an L-shaped supporting plate, a fixing groove, a T-shaped rotating seat and an anti-skid pad, wherein the connecting holes are formed in the middles of the interiors of the upper ends of the fixing seats respectively; and the fixing seats are arranged on the left side and the right side of the lower end of the first connecting plate respectively. According to the thread jumping prevention device, through arrangement of sliding blocks, connecting columns, metal hoses, inserting seats and ceramic thread guide hooks, when textile threads are stuck in the using process, the textile threads pull the ceramic thread guide hooks to drive the metal hoses to rotate, the textile thread buffering work can be conveniently carried out in theusing process, and the threads are prevented from being broken in the working process.

Owner:邵阳市昌兴实业有限公司

An Intelligent Petroleum Coke Production Equipment

ActiveCN110976021BFacilitate the realization of intelligent production workEasy maintenanceDrying gas arrangementsGrain treatmentsThermodynamicsElectric machine

Owner:唐山市曹妃甸燊融新材料科技有限公司

A brown sugar ginger tea quick packer

The invention relates to a quick packaging machine for black sugar ginger tea. The quick packaging machine comprises a shell, a feeding device, a cutting device, a control device and a packaging device. The feeding device is located at the upper end of the shell, and the cutting device and the control device are arranged in the shell. The packaging device is located on the outer surface of the lower end of the shell. According to the quick packaging machine, the traditional manual packaging mode or other packaging modes through auxiliary tools are replaced with an overall black sugar ginger tea packaging system, in this way, the structure is simple, and operation is convenient; meanwhile, the working cost is reduced, the working efficiency is improved, and the selling profit is increased; the cutting device is arranged in the packaging machine, so that the working procedure of manual cutting is omitted, thus the labor intensity of staff is relieved, the production cost is reduced, and the working efficiency is improved; and meanwhile, the large pieces of black sugar ginger tea can be quickly and equally cut.

Owner:ANHUI JIHONG ENVIRONMENTAL PROTECTION TECH CO LTD

Feeding device for straw production and using method thereof

InactiveCN112623683ARealize height position adjustment workEasy accessConveyorsConveyor partsHydraulic cylinderAgricultural engineering

The invention discloses a feeding device for straw production. The feeding device for straw production comprises a feeding frame and an adjusting frame, wherein the adjusting frame is arranged on one side of the feeding frame, one end of the top of the feeding frame is fixedly connected with a stop lever, a plurality of fixed boxes are arranged in the middle of the top face of the feeding frame, and a rotating shaft is arranged above the feeding frame; and piston rods in hydraulic cylinders are controlled to move through the two hydraulic cylinders, the two piston rods drive two moving plates to move respectively, a straw body is clamped and fixed through clamping blocks on the two moving plates, and then a screw is driven to rotate through the output end of a motor. The screw penetrates through a nut base and is connected with the nut base through threads, and a bottom plate is driven to move through a connecting plate, so that the bottom plate moves along two sliding rails to drive the straw body to enter a processing machine, the feeding work is completed, manual feeding is not needed, the manual labor amount is reduced, the safety is improved, the length of the straw body entering the feeding device can be controlled, extra measurement of workers is not needed, time is saved, and the working efficiency is improved.

Owner:阜南县顺昌塑业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com