Phase change filling sealing material with built-in graphite fibers

A sealing material and graphite fiber technology, applied in the field of materials, can solve the problems of poor sealing effect and no phase change, and achieve the effect of facilitating transmission and improving sealing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

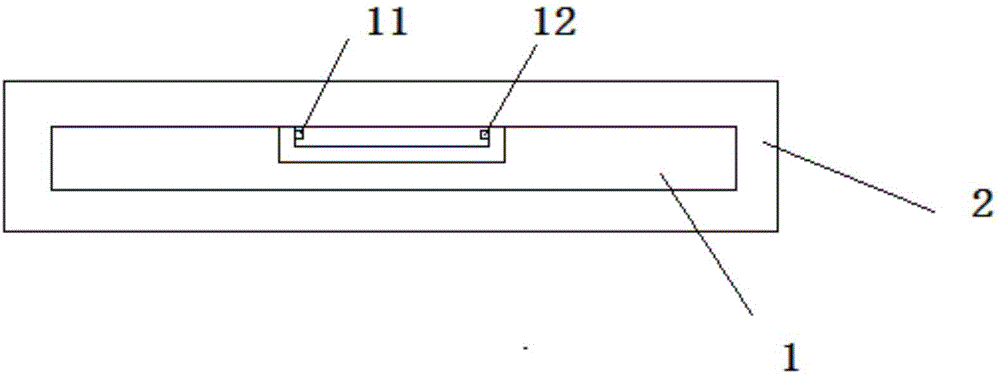

[0039] In order to make it easy to understand the technical means, creative features, objectives and effects achieved by the present invention, the present invention will be further explained below in conjunction with specific drawings.

[0040] See figure 1 , A phase-change filling and sealing material with built-in graphite fibers, the phase-change filling and sealing material includes the following components by mass percentage: 65% to 80% of thermal conductive particles, 5% to 20% of low melting point solid resin, and 10% to 20% of liquid resin %, coupling agent 0.02% to 2%; the thermally conductive particles include graphite fibers, and the weight of the graphite fibers accounts for 30% to 60% of the total weight of the thermally conductive particles. When the phase change filling and sealing material is lower than the melting point of the low melting point solid resin, it always maintains a solid state; when the phase change material is higher than the melting point of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com