Heavy-duty mine car cargo tank coating device

A coating and mine car technology, which is applied in the field of heavy machine mine car container coating device, can solve the problems of inconvenient container drying, inconvenient container guiding work, and different coatings affecting the coating quality, etc., to achieve Effect of moving up

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

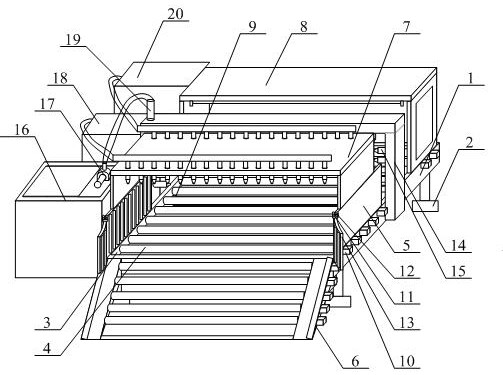

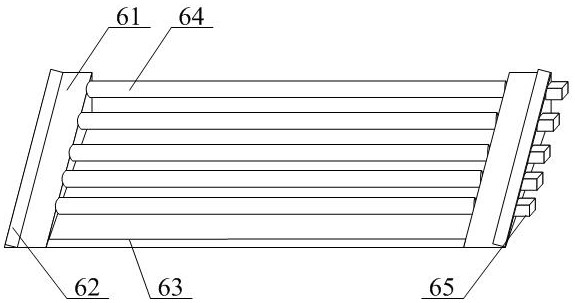

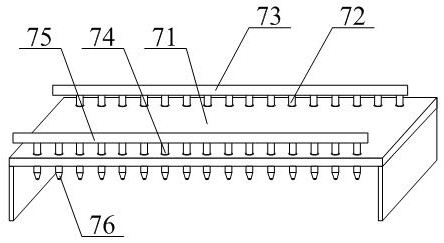

[0036] The present invention is described in detail below in conjunction with accompanying drawing, as appended figure 1 And attached figure 2 As shown, the coating device for heavy machinery mine car cargo box includes a coating seat 1, an inverted T-shaped support rod 2, a groove 3, a conveying roller 4, a first support plate 5, a guideable support frame structure 6, and a blower Dust removal frame structure 7, observable drying frame structure 8, collecting adsorption and scraping frame structure 9, conveying motor 10, fixing plate 11, wing bolt 12, arc plate 13, spraying box 14, coating tube 15, paint Box 16, painting pump 17, air pump 18, connecting pipe 19, suction fan assembly 20 and support roller 21, the inverted T-shaped support rod 2 is bolted to the four corners of the lower end of the painting seat 1; the groove 3 is set at the inner middle position of the coating seat 1; the conveying rollers 4 are sequentially arranged at the upper inner middle position of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com