Synchronous lifting and moving type feeding equipment of engineering machinery

A technology of synchronous lifting and construction machinery, which is applied in the field of construction machinery, can solve the problem that construction personnel cannot know the material transportation situation in time, and achieve the effect of reducing material spillage and facilitating observation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings.

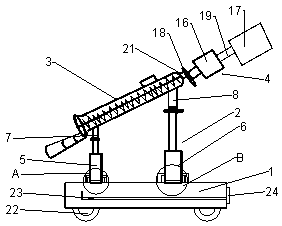

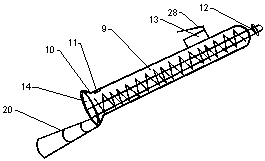

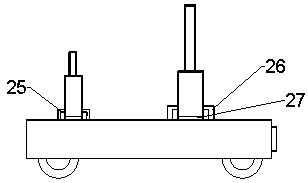

[0013] Such as Figure 1 to Figure 3 As shown, the present invention is a kind of synchronous liftable mobile feeding equipment for construction machinery, including a main body frame 1, a lifting system 2, a feeding device 3 and a kinetic energy system device 4, the upper part of the body frame 1 is connected to the lifting system 2, The upper part of the lifting system 2 is connected to the feeding device 3. The lifting system 2 is composed of a low lift 5 and a high lift 6. A low lift 5 is arranged on one side of the body frame 1 surface, and a high lift 6 is arranged on the other side of the body frame 1 surface. The feeding device 3 One end surface is welded with a fixed rod 7, the other end of the feeding device 3 is welded with a connecting rod 8, the top bolt of the low elevator 5 is connected with the fixed rod 7, the top bolt of the high elevator 6 is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com