Multifunctional code spraying machine for computer production and processing

A computer and multi-functional technology, applied in the direction of typewriter, printing, etc., can solve the problems of inconvenient computer guidance, inconvenient coding position adjustment, inconvenience, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

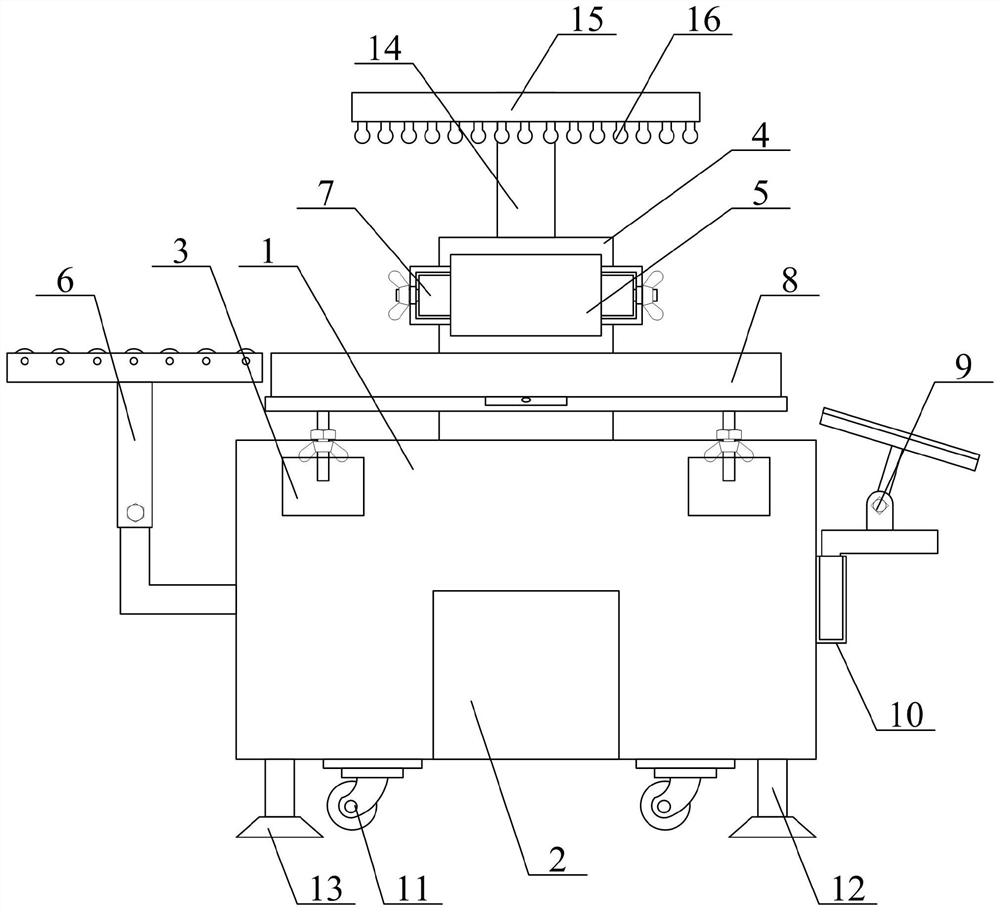

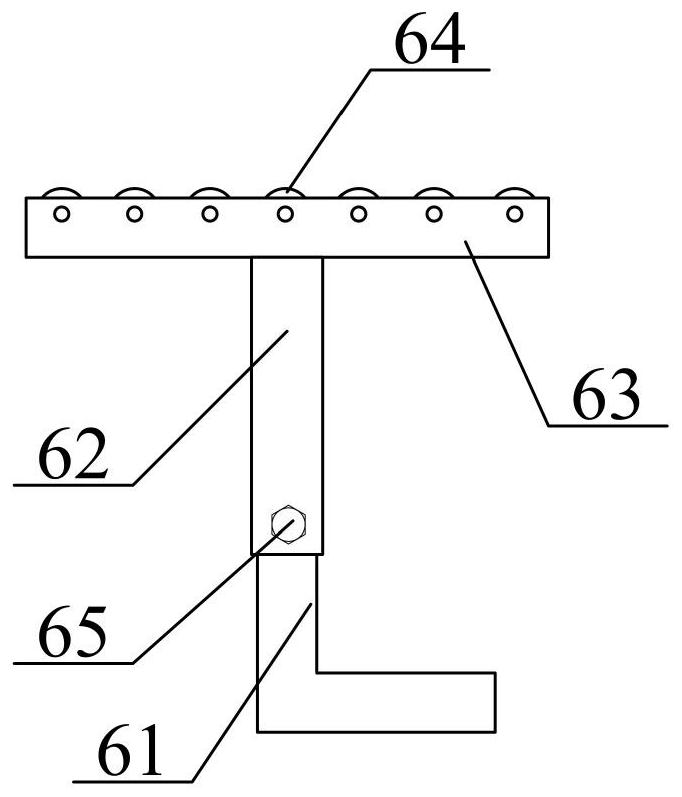

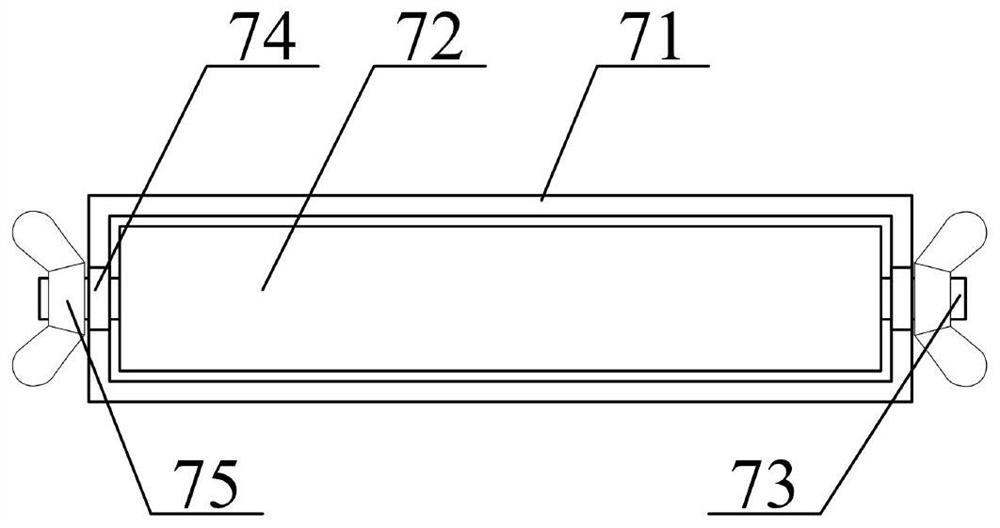

[0035] The present invention is described in detail below in conjunction with accompanying drawing, as appended figure 1 And attached figure 2As shown, a multi-functional computer production and processing inkjet printer includes a control cabinet 1, a ventilation hole 2, an operation hole 3, a coding box 4, a coding mechanism 5, a liftable push frame structure 6, and a retractable spraying frame. Code bracket structure 7, slidable and adjustable conveying seat structure 8, adjustable rotating guide plate structure 9, fixed seat 10, mobile brake wheel 11, threaded rod 12, adsorption seat 13, supporting lighting rod 14, lighting seat 15 and lighting lamp Beads 16, the ventilation holes 2 are provided at the lower part of the front surface of the control cabinet body 1; the operation holes 3 are respectively provided at the left and right sides of the upper part of the front surface of the control cabinet body 1; The bolt is connected to the middle position behind the upper en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com