Delivery device for loom

A technology of looms and swinging devices, applied in looms, weaving, textiles, and papermaking, etc., can solve problems such as large spaces, and achieve the effects of avoiding interference, easy operation, and reduced number of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

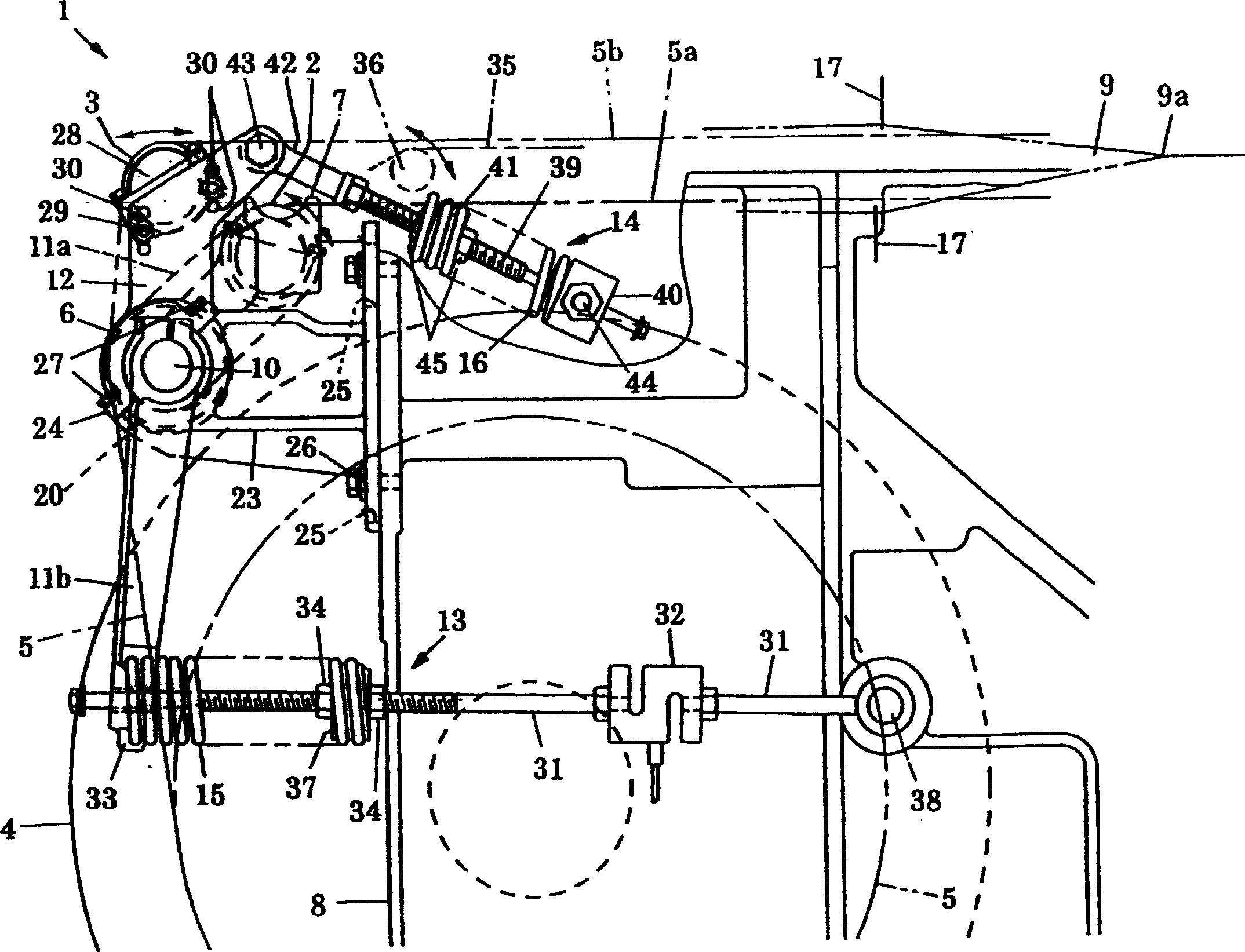

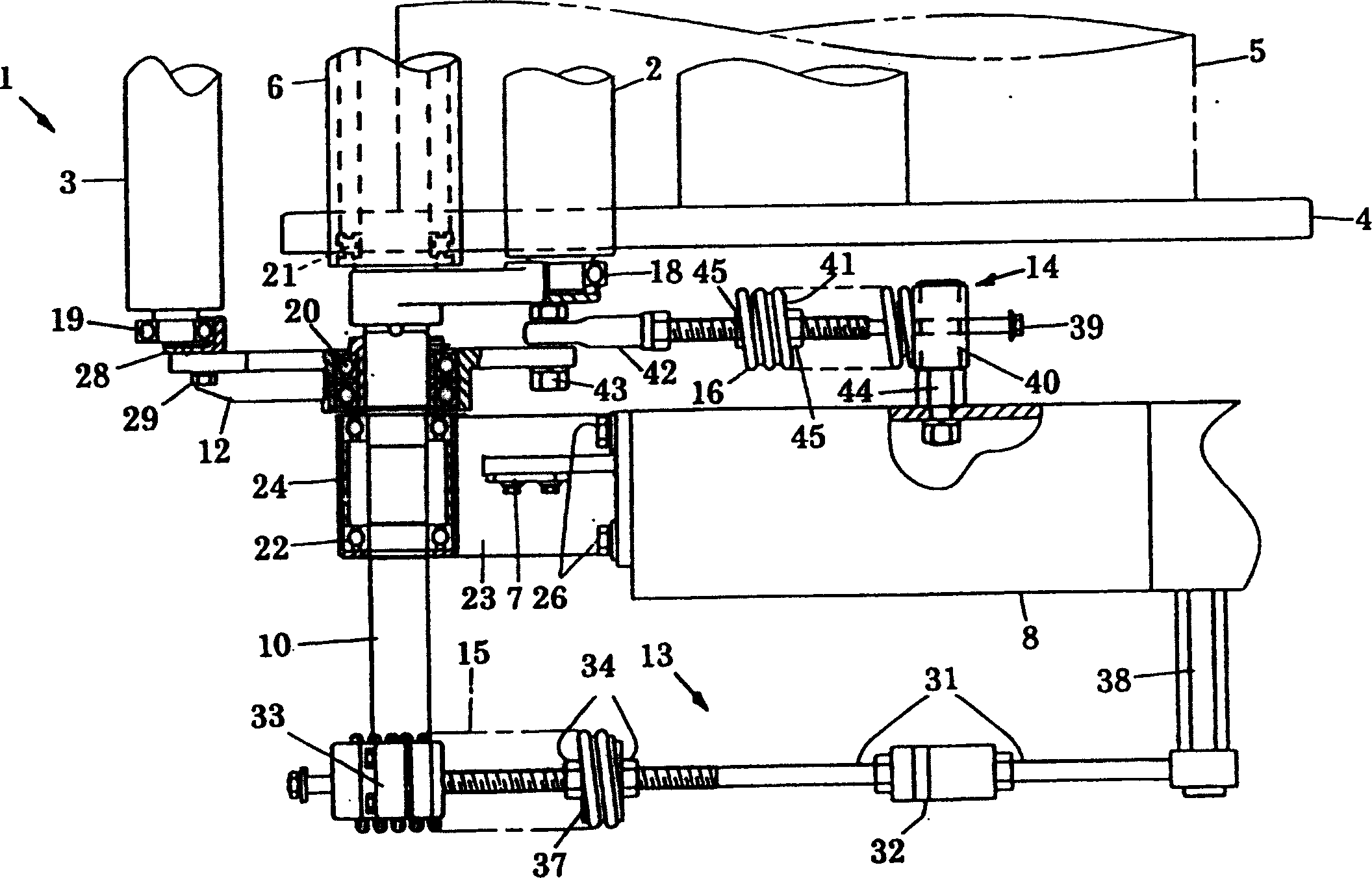

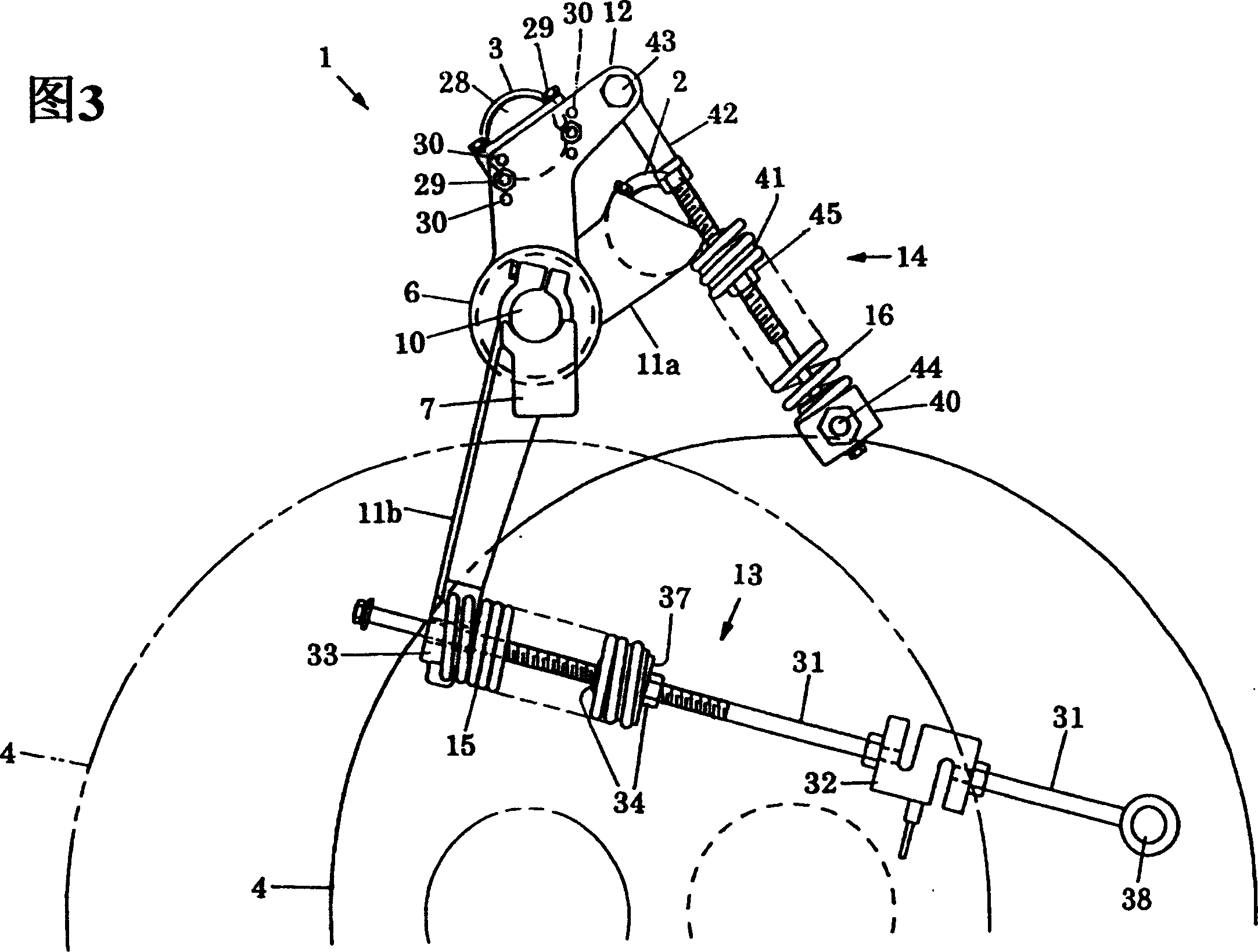

[0039] figure 1 , figure 2 And Fig. 3 shows the delivery device 1 of the loom of the present invention. in addition, figure 2 Only one side of the left and right pair of brackets 8 is shown, and the other side is omitted. The delivery device 1 of the loom comprises a plurality of, for example, two easing rollers 2, 3 and one guide roller 6. The left and right ends of the plurality of easing rollers 2, 3 are rotatably supported by bearings 18, 19 on the front ends of a pair of left and right easing levers 11a, 12, and the roots of the easing levers 11a are fixed in a stopped state. On the shaft 10 of the guide roller 6 , the root of the loosening lever 12 is rotatably supported on the shaft 10 of the guide roller 6 through a bearing 20 . In addition, another warp easing lever 11b described later is fixed to the shaft 10 of the guide roller 6, and the warp easing lever 11a passes through the shaft 10 of the guide roller 6 to form one lever together with the warp easing lev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com