A general performance comprehensive test system for the end effector of a special operation robot

A technology of end effectors and operating robots, which is applied to manipulators, manufacturing tools, etc., can solve problems such as low reliability, inability to link actions, and inability to ensure product quality and production efficiency, and achieve the effect of coherent and stable actions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings.

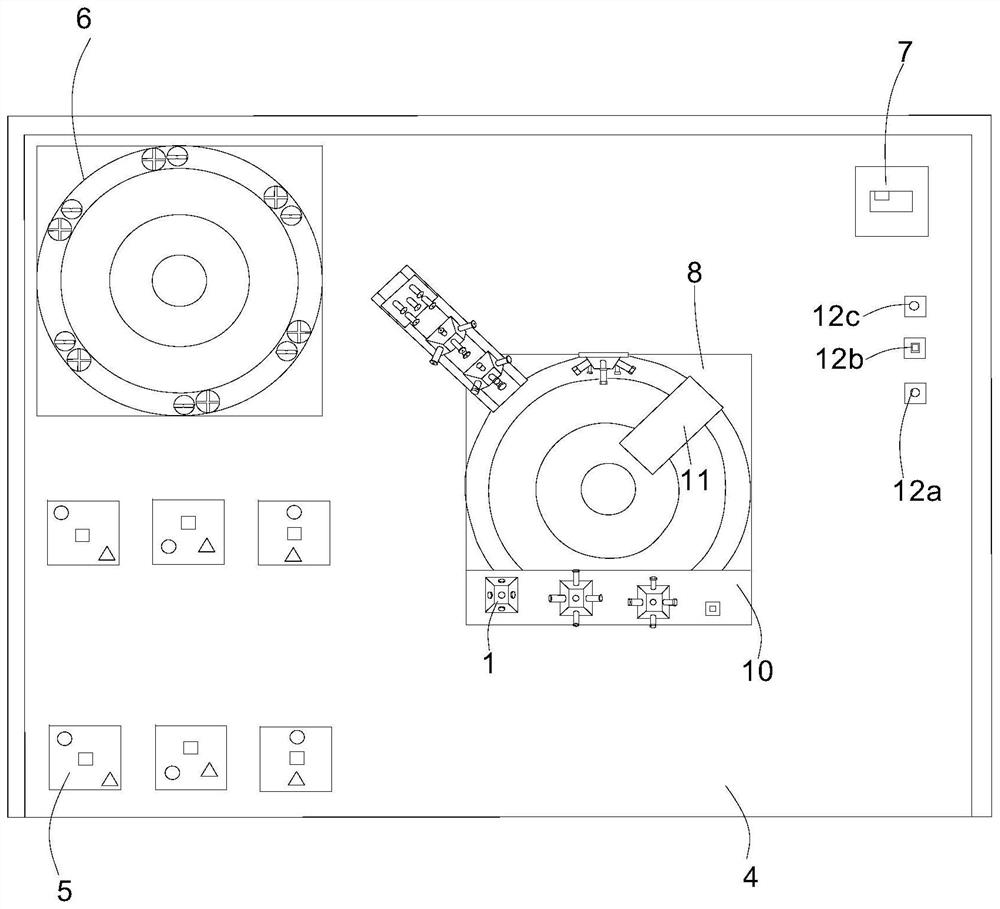

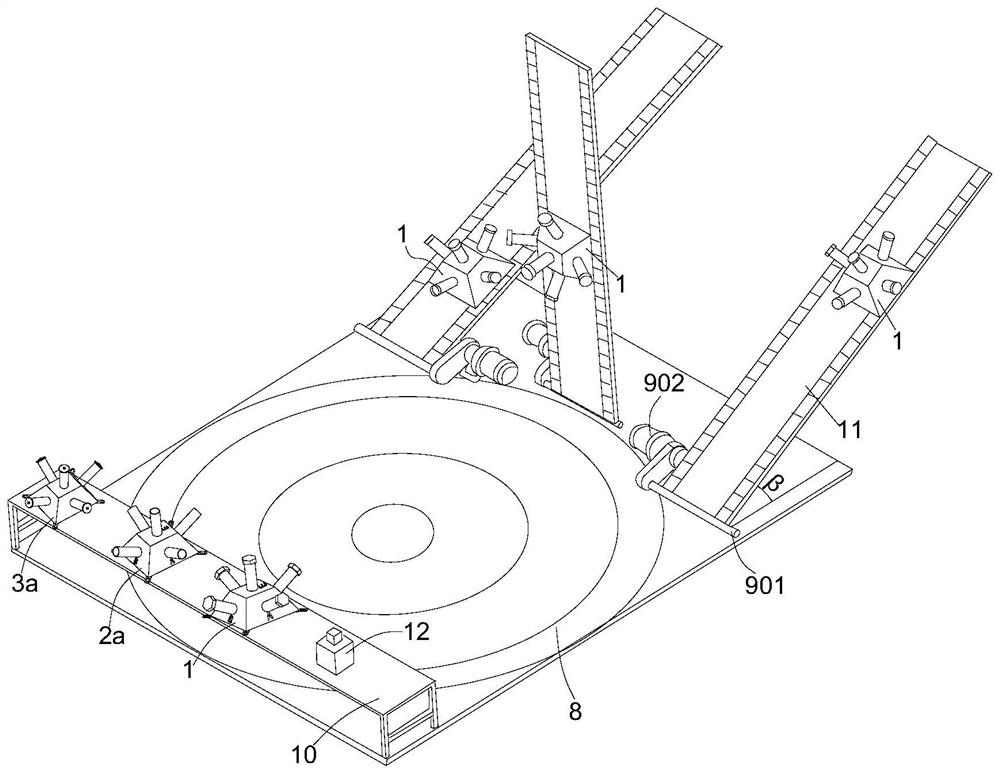

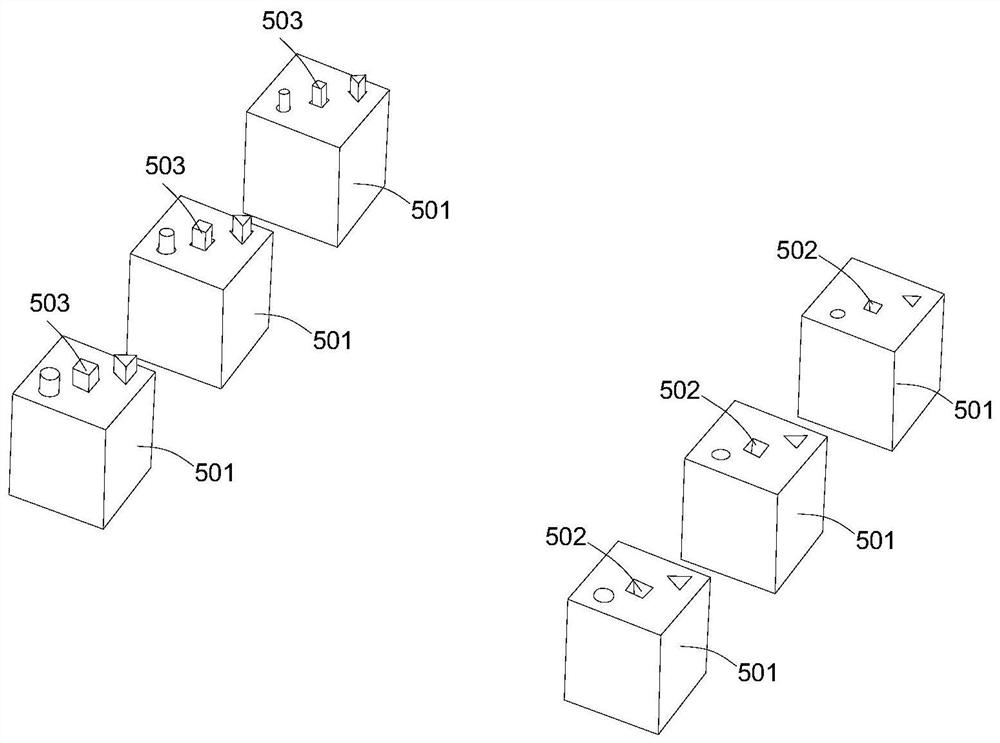

[0031] see Figure 1 to Figure 16 , the present invention provides a general performance comprehensive test system for a special operation robot end effector, comprising an end effector visual detection test unit, an end effector touch test unit 3, an end effector rotation and removal test unit 1, an end effector load The test unit 601, the end effector accuracy test unit 5, the end effector torque test unit 7, the end effector stability test unit 12, the loading platform 4 and the main control computer; each of the test units is connected to the main control computer, Each test unit and the main control computer are connected by a wireless communication module. The preferred requirements of the main control computer are: quad-core processor, RAM: 8G, storage: 2TB and above, graphics card: NVIDIA GeForce GTX1050 equivalent performance Graphics card, network: Gigabit E...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com