A multi-stage compound telescopic hydraulic cylinder for heavy load

A telescopic hydraulic cylinder, heavy load technology, applied in the direction of fluid pressure actuation device, mechanical equipment, etc., can solve the problems of slow extension speed, affecting lifting work efficiency, vibration impact, etc. Difficulty in processing and manufacturing, the effect of eliminating synchronization errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the purpose, content, and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

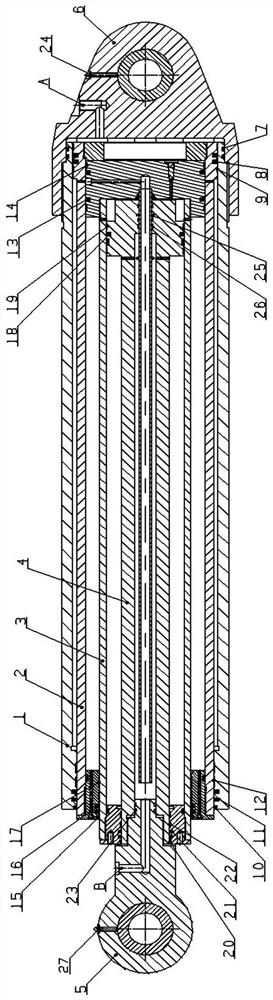

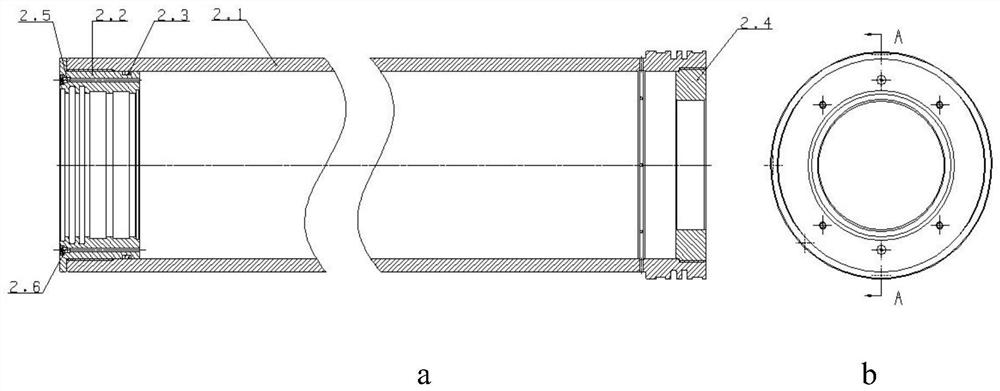

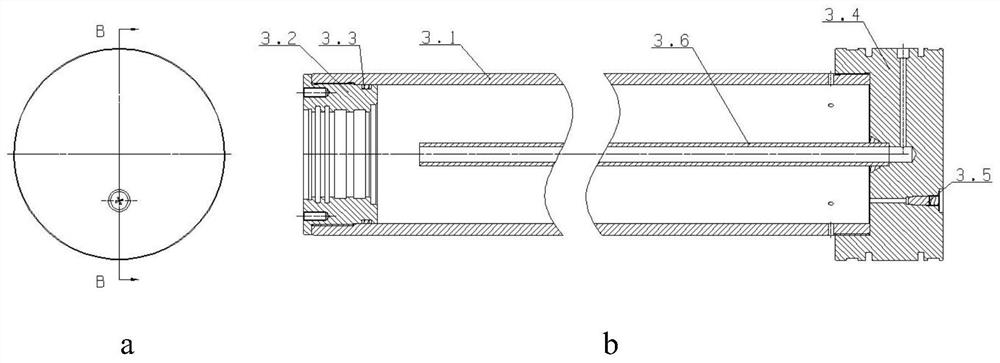

[0025] like figure 1 As shown, the present invention provides a multi-stage compound telescopic hydraulic cylinder suitable for heavy loads, including a cylinder barrel 1, a first-stage cylinder 2, a second-stage cylinder 3, a third-stage cylinder 4, a cylinder head 5, a cylinder bottom 6 and different specifications O-rings, gray rings, guide rings, dust-proof rings and oil cups, of which:

[0026] like figure 1 As shown, the cylinder 1, the first-stage cylinder 2, the second-stage cylinder 3 and the third-stage cylinder 4 are sequentially nested from outside to inside. The first dust-proof ring 10, the second gray ring 11, and the second guide ring 12 are installed in sequence, and are sealed and supported with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com