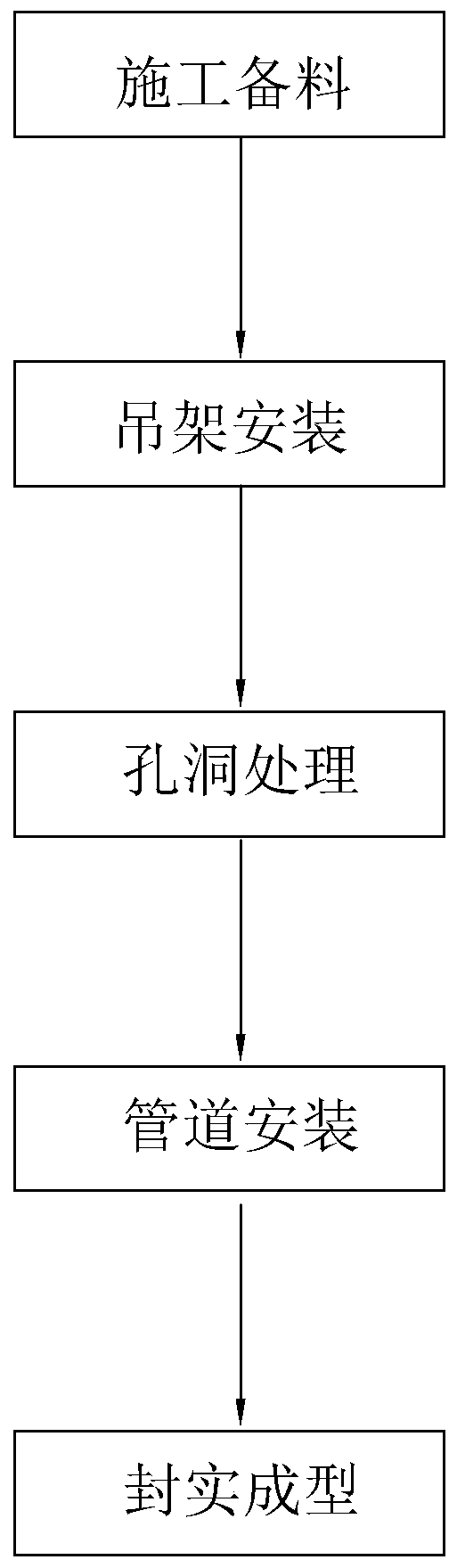

Pipeline laying construction process

A construction technology and pipeline laying technology, applied in pipeline laying and maintenance, mechanical equipment, pipes/pipe joints/fittings, etc., can solve the problems of poor overall application effect, damage, pipeline stress concentration, etc., and achieve good application effect, Improved stability, good application effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1: a kind of construction technology of pipeline laying, it specifically comprises the following steps:

[0035] Step 1: Preparation of construction materials, preparation of construction machinery and common materials, inspection and acceptance of pipelines, preparation of construction plans, and technical disclosure and safety disclosure to construction personnel;

[0036] Step 2, hanger installation, using expansion bolts to fix the movable hanger and anti-shake hanger on the wall, and the movable hanger is set on both sides of the expansion joint, settlement joint or seismic joint, and the anti-shake hanger is set on the movable the outer sides of the hangers away from each other;

[0037] Step 3, hole treatment, grinding and cleaning the inner wall of the hole where the pipeline needs to be pierced, and then painting the elastic rubber protective layer on the inner wall of the hole, and waiting for it to cure;

[0038] Step 4, pipeline installation, set...

Embodiment 2

[0041] Embodiment 2: A construction process for laying pipelines. The difference from Embodiment 1 is that in step 2, a flexible telescopic tube connecting the pipeline is provided between the movable hanger and the anti-shake hanger, and the flexible telescopic tube Both ends of the pipe are fixed on the pipe by flanges.

Embodiment 3

[0042] Embodiment 3: A construction process for laying pipelines. The difference from Embodiment 1 is that, in Step 4, the pipelines are located at both ends of the holes and provided with square compensators.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com