A Composite Fire Hydrant Interface

A fire hydrant and interface technology, which is applied in the direction of pipes/pipe joints/fittings, couplings, pipe components, etc., can solve the problems of rescue of difficult trapped persons, low connection strength, slow processing speed of fire hydrants, etc., and achieve fast Fire extinguishing efficiency, efficient effect of fire extinguishing work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

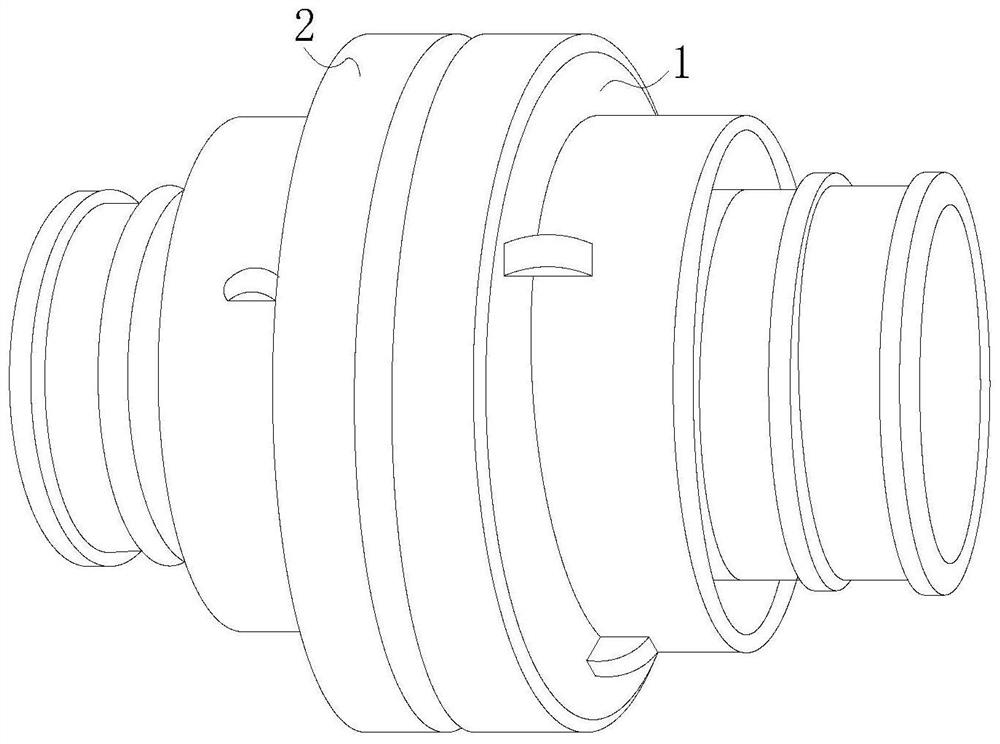

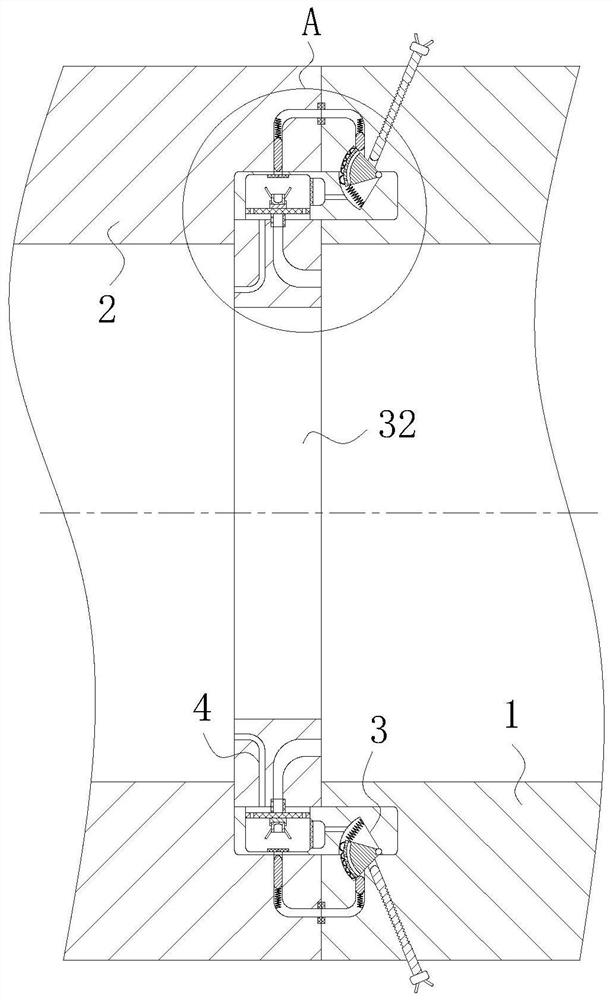

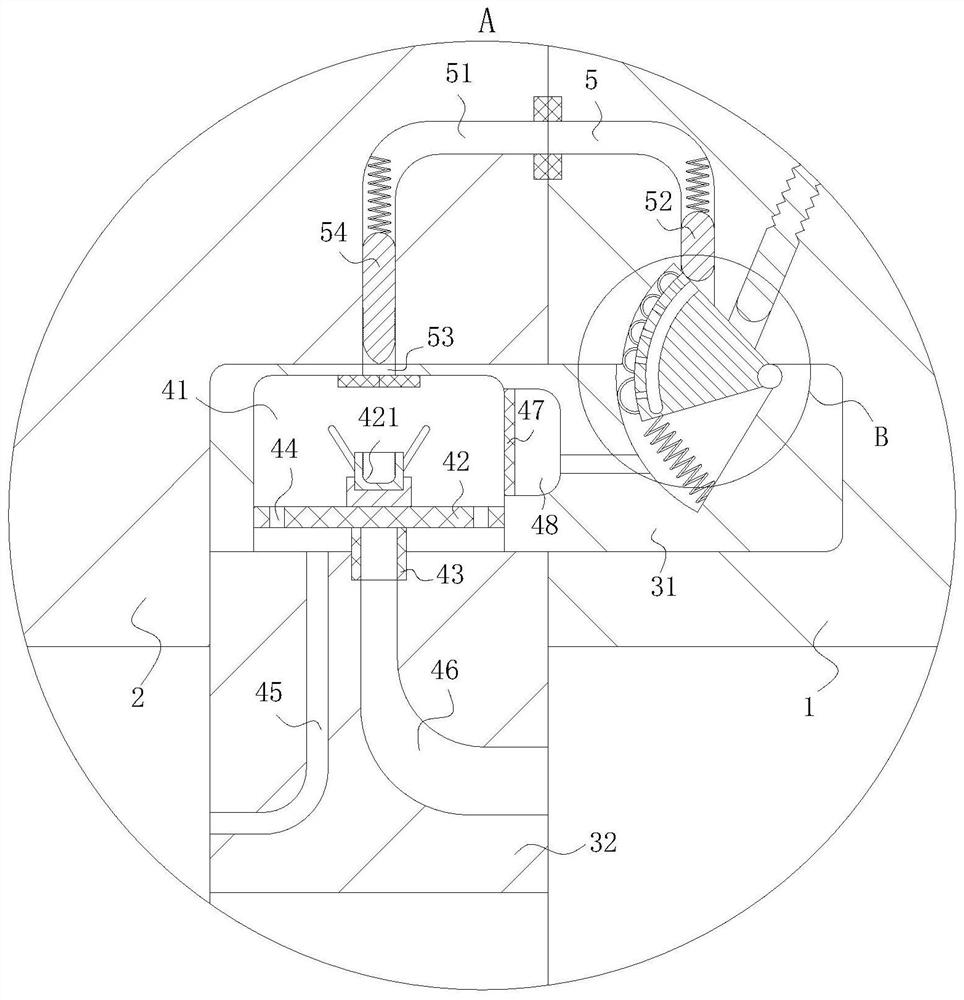

[0019] use Figure 1-Figure 4 A composite fire hydrant interface according to an embodiment of the present invention is described as follows.

[0020] Such as Figure 1-Figure 4As shown, a composite fire hydrant interface of the present invention includes a water outlet pipe 1, a water spray pipe 2, a plug-in fixing mechanism 3 and an acceleration mechanism 4; the water spray pipe 2 is fixedly connected to the left end of the water outlet pipe 1, The right end of the spray pipe 2 is provided with a plug-in fixing mechanism 3; the plug-in fixing mechanism 3 includes a plug-in ring 31, a fixed ring 32, a mounting groove 33, a rotating block 34 and a reset lever 35; the plug-in ring 31 is fixed Connected to the outer surface of the fixed ring 32, the integral connection formed by the insertion ring 31 and the fixed ring 32 is fixedly installed in the right end wall of the water spray pipe 2, and the right end of the insertion ring 31 can be inserted into the left end wall of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com