Line inspection robot based on planetary gear mechanism and obstacle crossing method

A line patrol robot and planetary gear technology, which is applied to overhead lines/cable equipment, etc., can solve the problems of low efficiency and unstable obstacle crossing of the line patrol robot, so as to improve work efficiency, improve obstacle crossing efficiency, and have a simple and practical structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

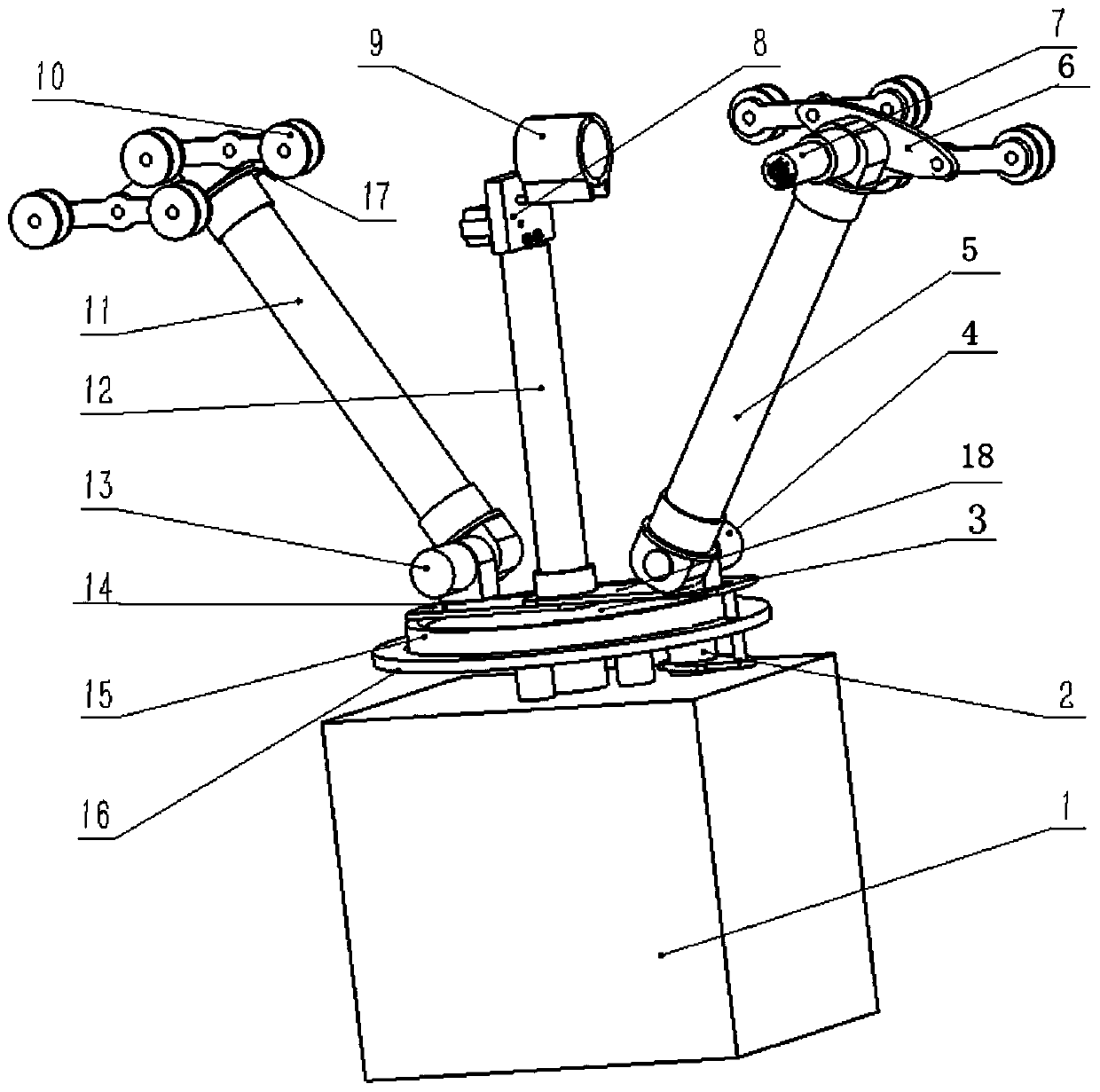

[0033] Such as figure 1 Shown: a line patrol robot based on a planetary gear mechanism, which includes a box body 1, a planetary gear mechanism is fixedly installed on the top of the box body 1; a traveling clamping device and a self-powering device are installed on the planetary gear mechanism.

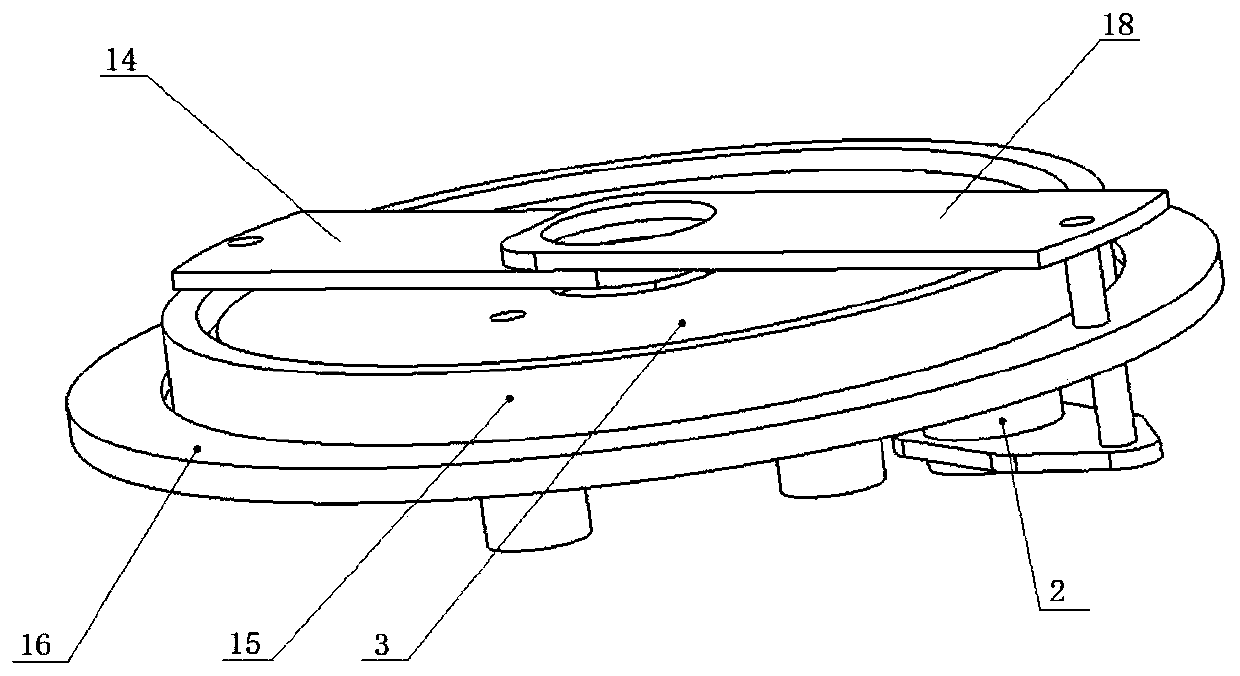

[0034] The central fixed disk 3 is fixedly installed on the top of the box body 1 by bolts; the center of the central fixed disk 3, the toothed inner ring 15 and the toothed outer ring 16 are provided with openings, and the aperture is equal to the outer diameter of the telescopic rod 12, and the matching relationship It is a loose fit to ensure no binding when turning.

[0035] As shown in Figure 2: the toothed inner ring 15 is located between the central fixed disk 3 and the toothed outer ring; the steering motor 2 is installed at the bottom of the central fixed disk 3; the rotating shaft of the steering motor 2 is a gear type, and the pitch of the gear Etc. are consistent with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com