Cleaning device for automobile part production

A technology for auto parts and cleaning devices, which is applied to the cleaning method using tools, the cleaning method using liquid, and the arrangement of drying gas, which can solve the problems of unsatisfactory cleaning effect, secondary pollution of workpieces, and inability to dry immediately

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

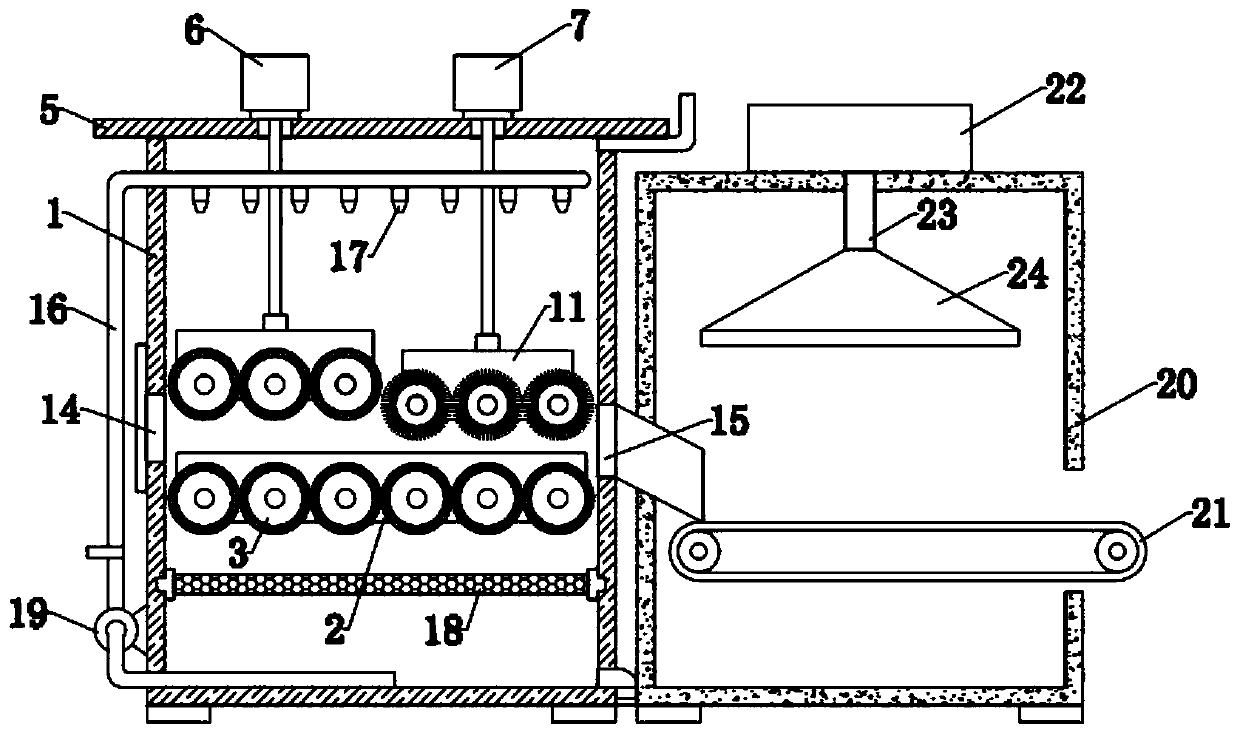

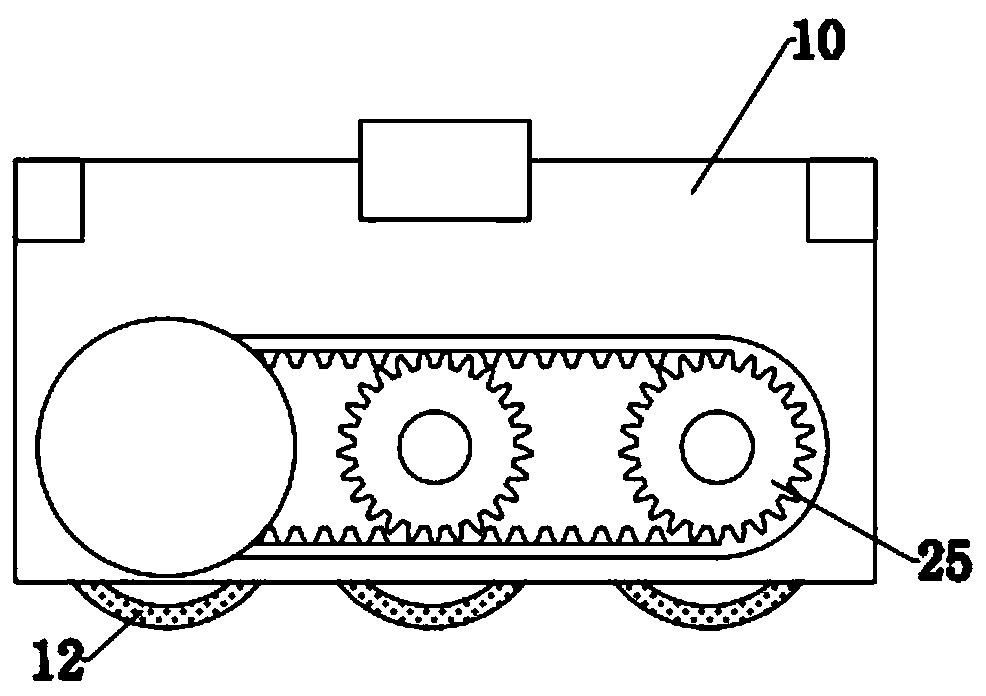

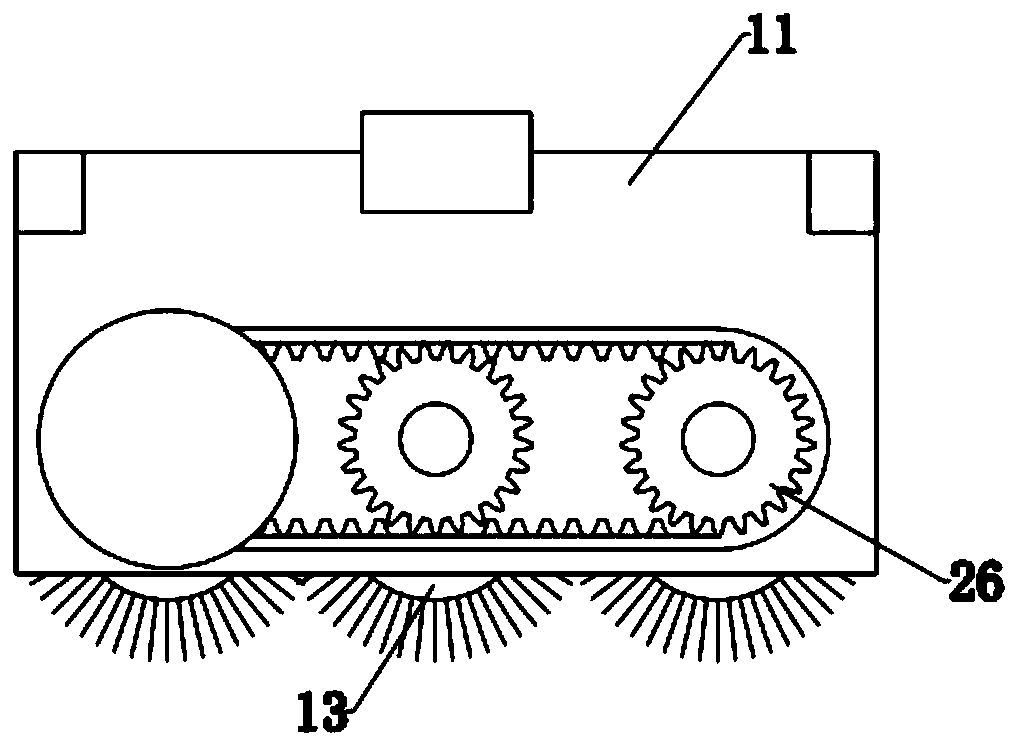

[0033] refer to Figure 1-7 It can be seen that a cleaning device for the production of auto parts in the present invention includes a cleaning box 1, the inner and rear walls of the cleaning box 1 are integrally provided with a fixing plate 2, and the gap between the fixing plate 2 and the front inner wall of the cleaning box 1 is Rotate the lower cleaning brush 3 equidistantly through the bearing, the rear end of the lower cleaning brush 3 extends to the rear outer wall of the cleaning box 1, and a drive mechanism I4 is installed on the top of the cleaning box 1. A top plate 5 is installed on the top of the cleaning box 1. Servomotor I6 and servomotor II7 are respectively installed on the left and right sides of the upper end of the top plate 5, and the output ends of the servomotor I6 and servomotor II7 are respectively installed with ball s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com