Rod line head aligning device

A head-to-head and wire-to-head technology, which is applied in the field of rod-to-wire head-to-head devices, can solve problems such as increasing the load of the oil cylinder, increasing the friction between the baffle plate and the chute, and increasing production costs, so as to achieve the effect of reducing failures and weakening the degree of influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

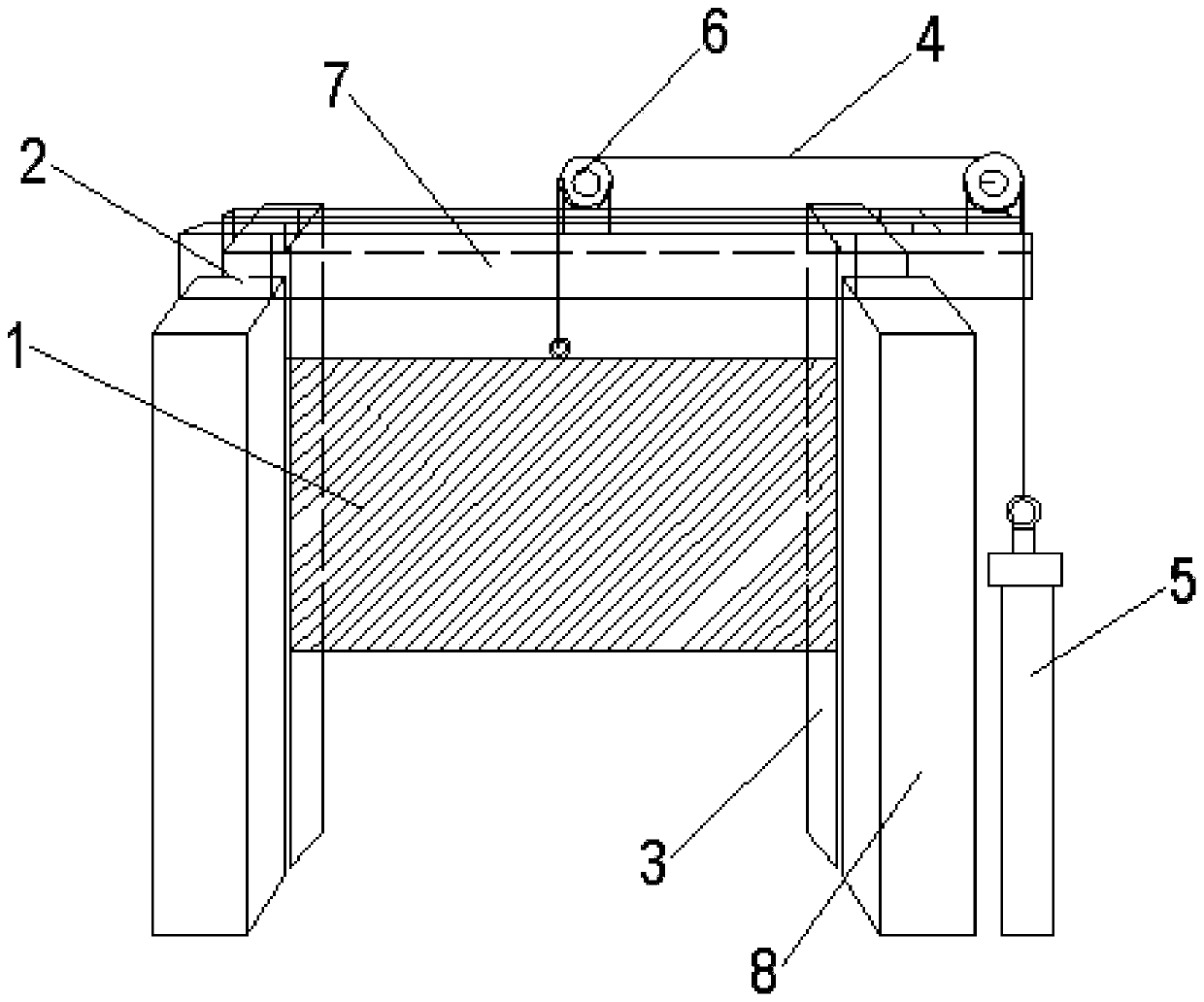

[0015] In order to facilitate understanding of the present invention, the present invention will be further described below in conjunction with the accompanying drawings.

[0016] Such as figure 1 As shown, the bar and wire aligning device of the present invention includes a mounting base 2 and a liftable aligning plate 1, a backstop 3 is provided behind the aligning plate 1, and the aligning plate 1 and the tailgate 3 are matched to each other. The rods and wires are aligned, and the back baffle 3 is also used as a load-bearing part when the rods and wires are impacted. The stopper 3 prevents it from retreating under force, and the rods and wires are braked by the plane of the trimming board 1 to achieve the purpose of trimming. After the trimming is completed, the trimming board 1 is raised, and the rods and wires are bundled and passed through to enter the follow-up work.

[0017] In the present invention, the lift of the head-to-head board 1 is realized through the joint ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com