Positioning device and construction method for reserved sleeve inserting ribs in the transfer layer of prefabricated buildings

A positioning device and transfer layer technology, applied in the direction of buildings, building components, building reinforcements, etc., can solve the problems of inability to install the upper prefabricated structure, inaccurate positioning of sleeve insertion ribs, and difficult fixation, etc., to achieve simple structure and solve positioning The effect of prohibiting and reusing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

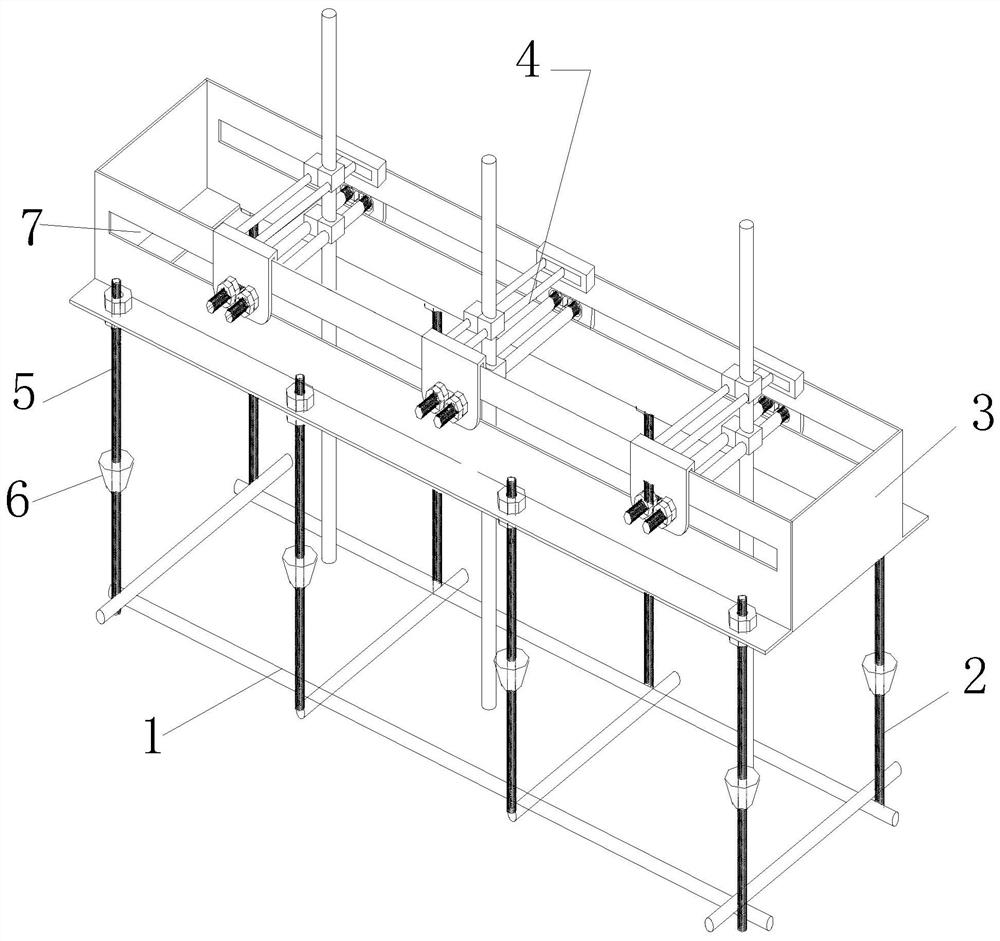

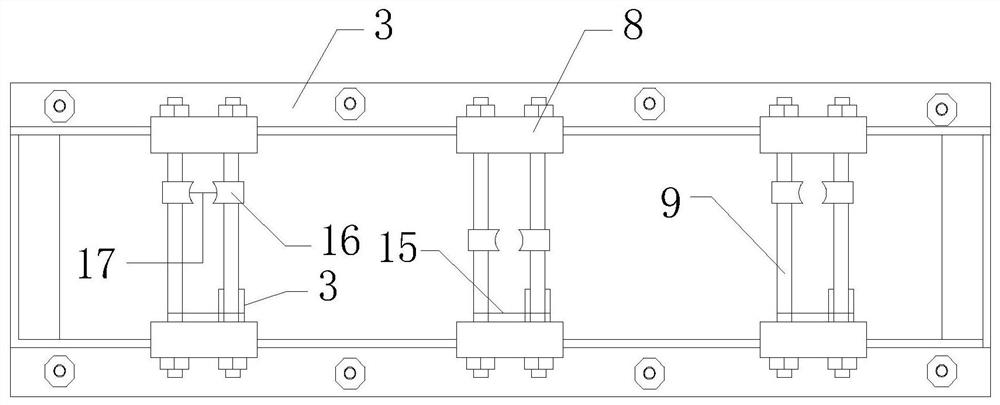

[0031] Such as Figure 1 to Figure 4 As shown in the figure, the casing inserting bar positioning device is reserved for the transfer layer of the prefabricated building, including a fixed frame 1 and a positioning mechanism. Eight floor thickness control parts 2 are welded and fixed on the fixed frame 1, and the top of the floor thickness control part 2 is provided with a connection Part 6, the top surface of the poured concrete is flush with the top surface of the connecting part 6. The connecting part 6 is a conical structure with a large upper part and a smaller lower part, which is convenient for dismantling and reusable to save cost when demoulding later, and the upper and lower ends are respectively provided with Threaded hole, the connecting piece 6 is screwed to the top of the floor thickness control piece 2.

[0032] The positioning mechanism is located on the top of the fixed frame 1. The positioning mechanism includes a construction platform 3 and a clamping unit 4...

Embodiment 2

[0036] Such as Figure 5 Shown, the construction method of this device comprises the following steps:

[0037] Step 1. Fix the fixed frame 1 and the main steel structure, and level it to the levelness required by the design, so as to provide a levelness reference basis for the construction platform 3;

[0038] Step 2. Thread the bottom of the adjustment part 5 to the top of the connection part 6, and pass the top of the adjustment part 5 through the construction platform 3. Adjust the construction platform 3 to a horizontal state by adjusting two nuts to ensure that the reserved sleeve The angle of insertion of the ribs;

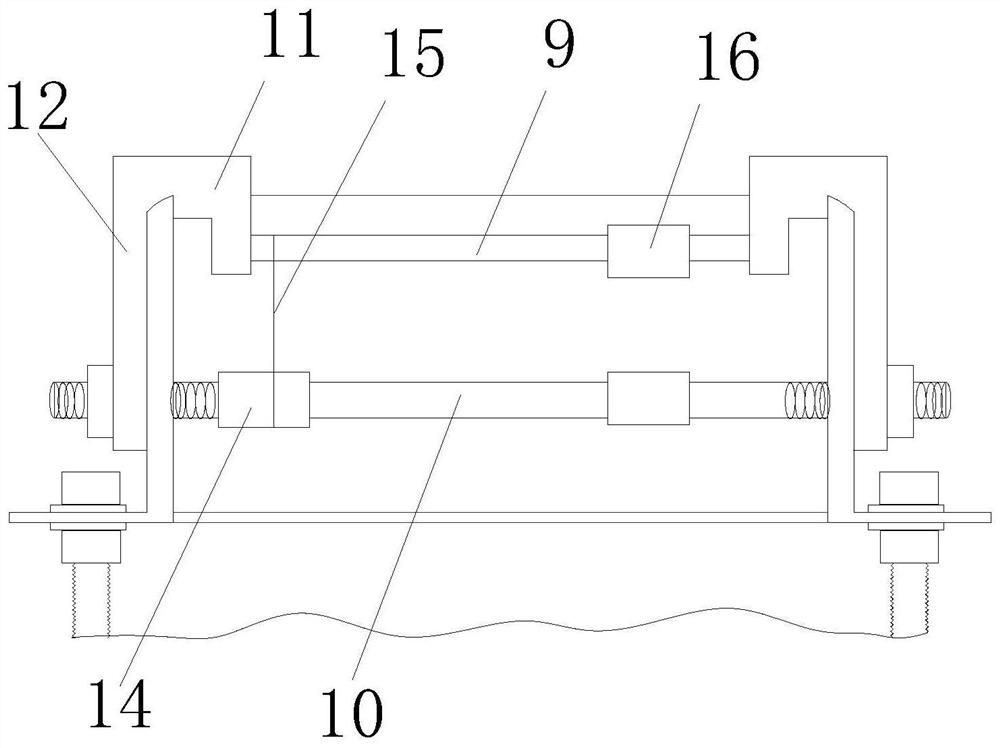

[0039] Step 3: Assemble the two positioning rods 9 provided with positioning blocks 16 into the waist hole 13 of the buckle 11 of the adjusting gasket 8, and ensure that one is fixed and the other can move horizontally, using the buckle 11 of the adjusting gasket 8 Fasten on the construction platform 3, and then pass through the two connecting parts 12 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com