Friction and wear test tooling

A technology of friction and wear test and tooling, which is applied in the direction of testing wear resistance, etc., can solve the problems of high price, large investment of small enterprises, and lack of operability, and achieve the effect of cost reduction and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

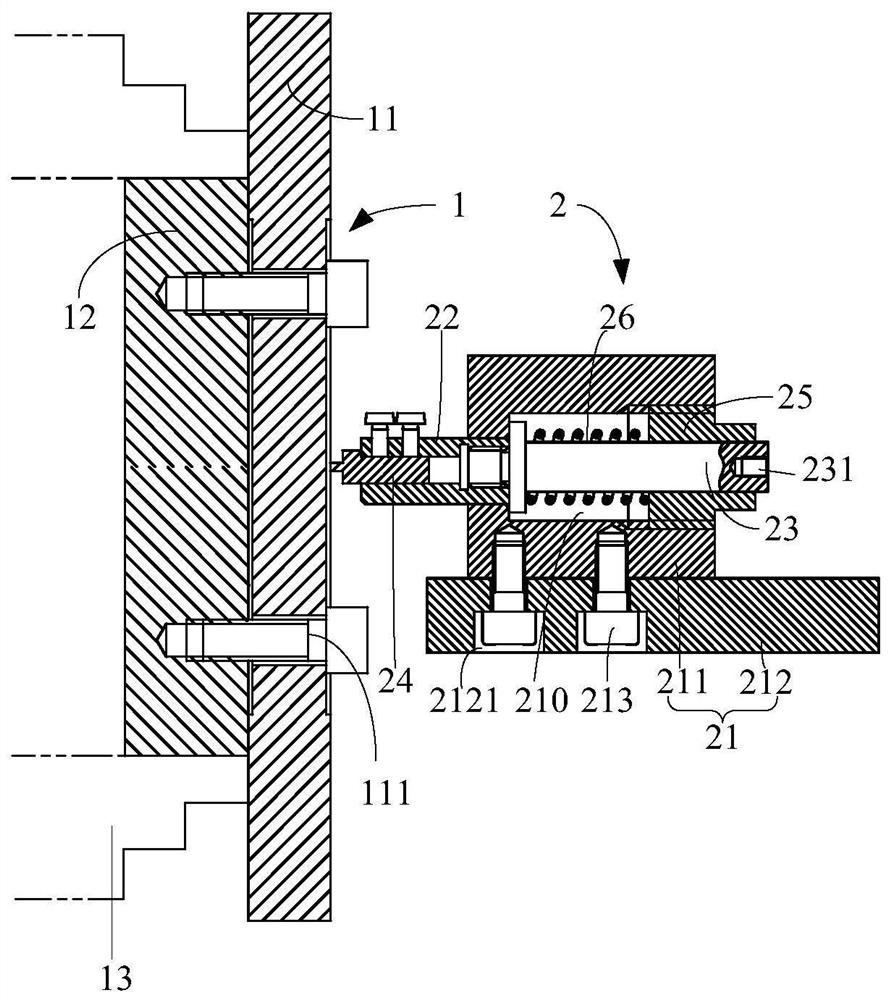

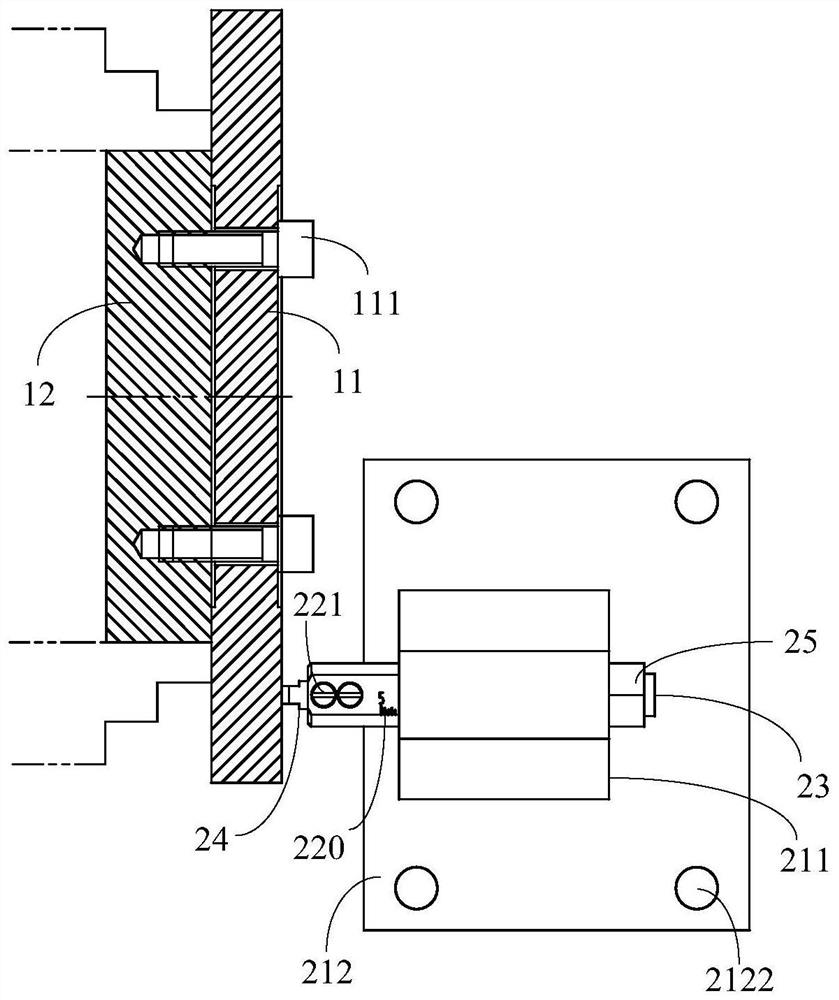

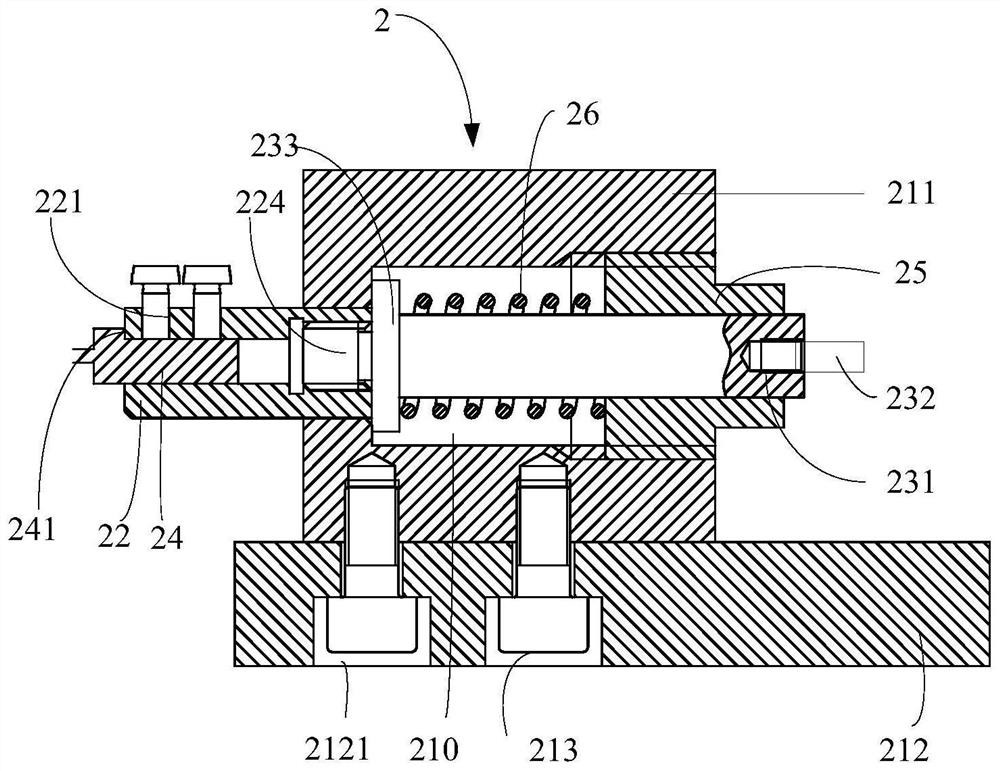

[0027] Embodiments of the present invention provide a friction and wear test tool, such as figure 1 As shown, the friction and wear test fixture includes a rotating unit 1 and a load unit 2 , and the rotating unit 1 includes a friction disc 11 . The load unit 2 includes a support base 21, a pin sleeve 22, a connecting rod 23, a friction pin 24, a fastener 25 and a spring 26, the support base 21 is provided with a mounting hole 210, and the connecting rod 23 is inserted in the mounting hole 210, tightly The firmware 25 is slidably sleeved on one end of the connecting rod 23, and the fastener 25 is fixedly installed in the mounting hole 210, the spring 26 is sleeved on the connecting rod 23, and one end of the spring 26 is fixedly connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com