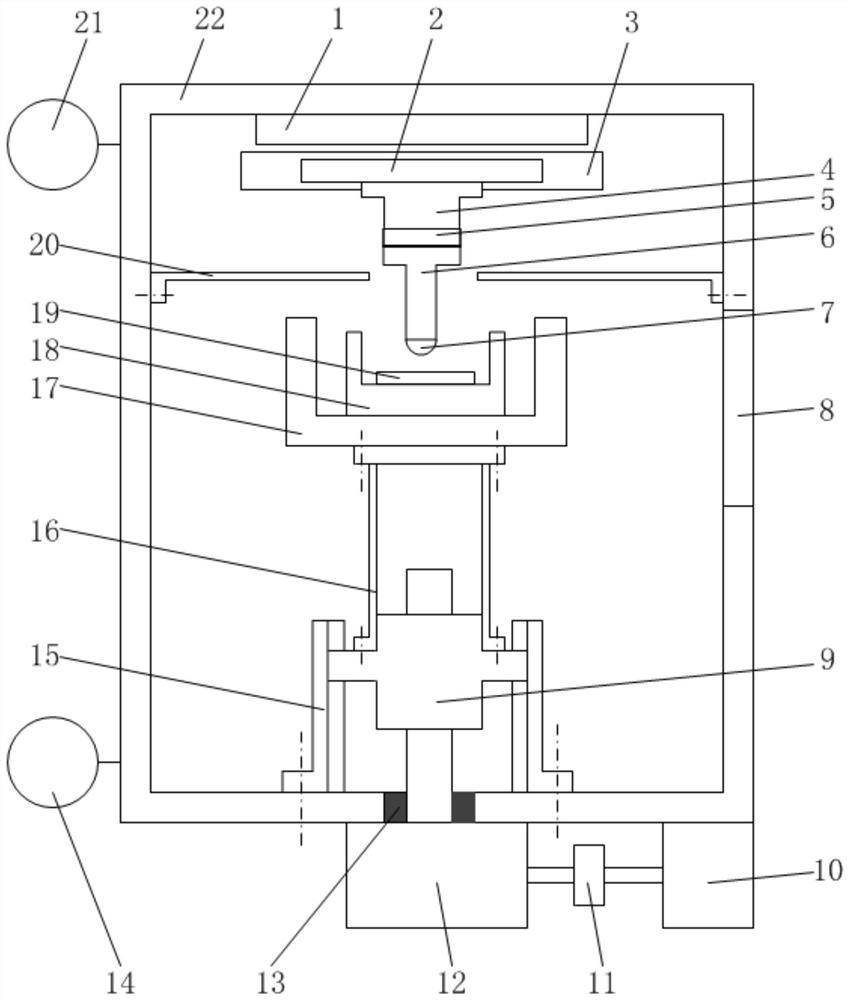

Vacuum high-temperature reciprocating type frictional wear testing system

A friction and wear, reciprocating technology, applied in measuring devices, instruments, mechanical devices, etc., can solve the problems of hindering the research of lubricants and aviation materials, still need to be improved, expensive and other problems, and achieves low production cost, simple structure, Stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

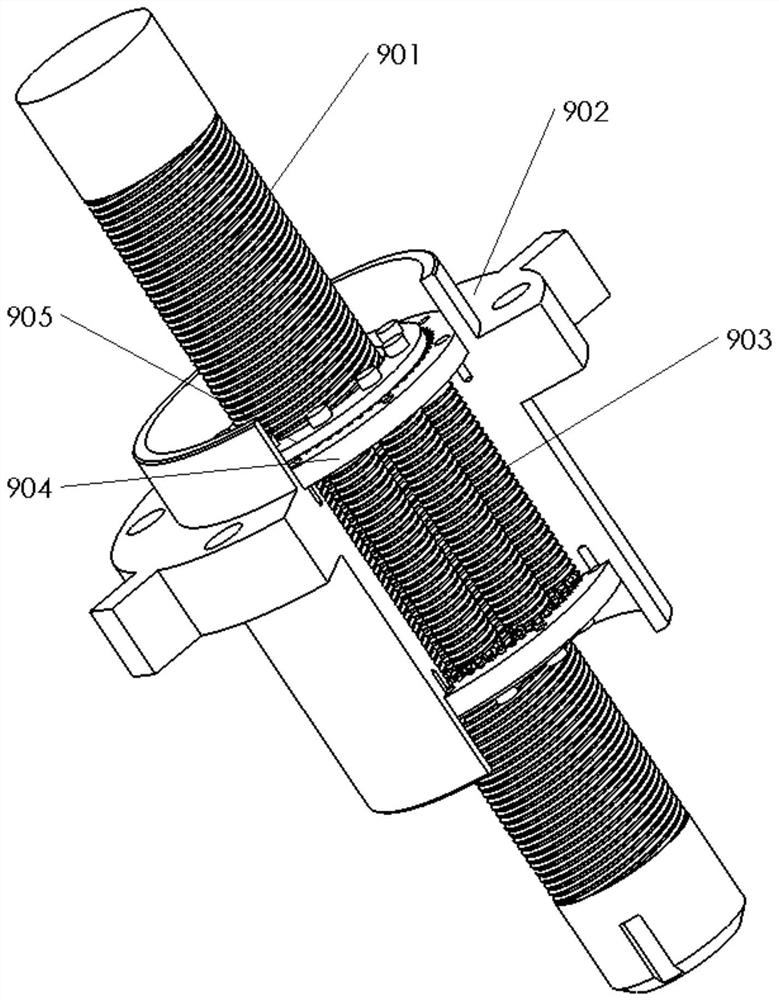

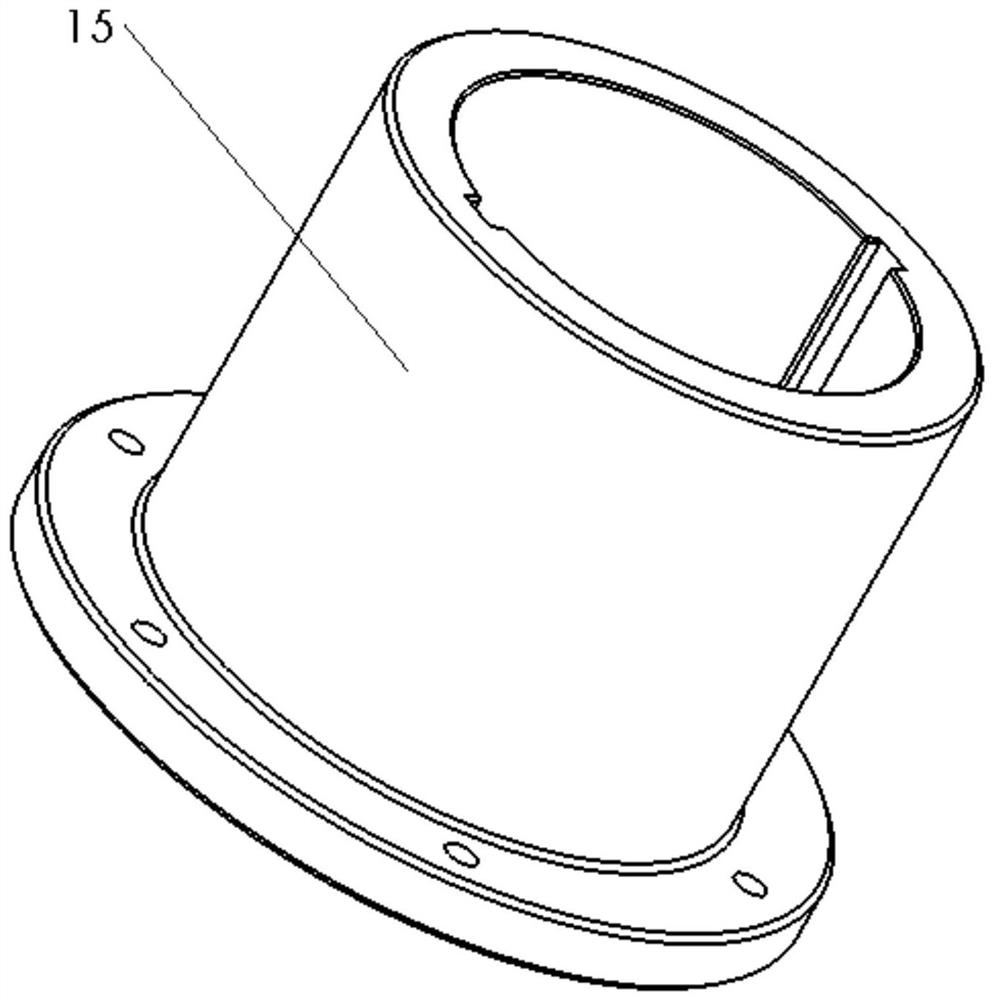

[0025] When the vacuum high-temperature reciprocating friction and wear testing system of the present invention is working, the linear motor mover 2 drives the connecting seat 4, the two-dimensional force sensor 5, the test ball mounting seat 6, and the test ball 7 to perform reciprocating linear motion, and the reciprocating frequency is passed by the linear motor Adjustment; the servo motor 10 provides the rotating power source for the screw 901 through the shaft coupling 11 and the reducer 12. When the guide base 15 is used to limit the rotational freedom of the ear nut 902, the screw 901 and the roller 903, the roller The cooperation between 903 and ear nut 902 converts the rotary motion of the screw rod 901 into the linear feed motion of the ear nut 902, thereby realizing the 902 linear feed movement.

[0026] The vacuum system 14 provides the vacuum environment required for the test; the induction heating furnace 17 provides the temperature from 25°C to 800°C; the data a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com