Fruit picking robot for orchard

A technology for picking robots and fruits, applied in picking machines, applications, manipulators, etc., can solve problems such as low efficiency, economic loss, and heavy labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

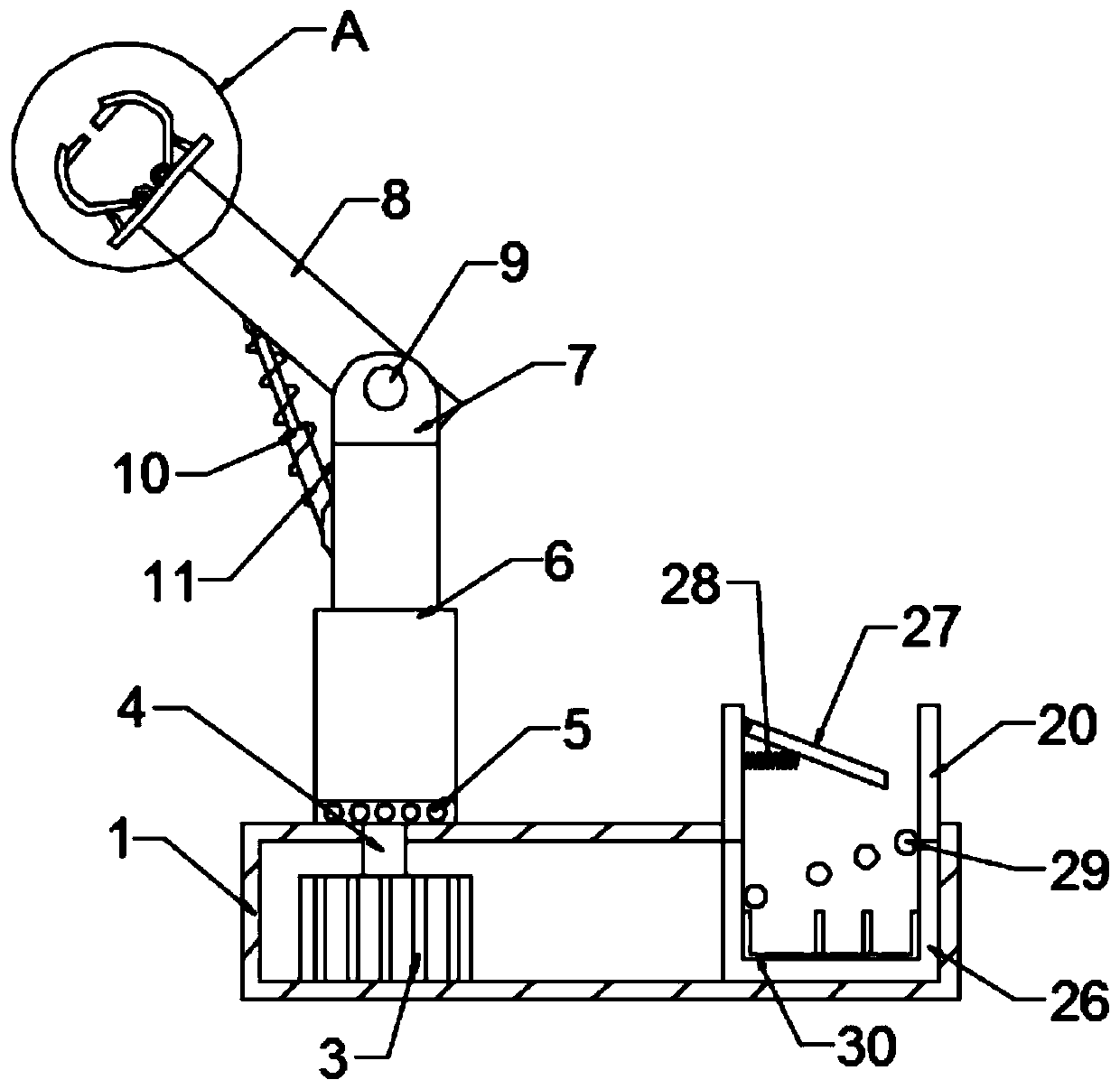

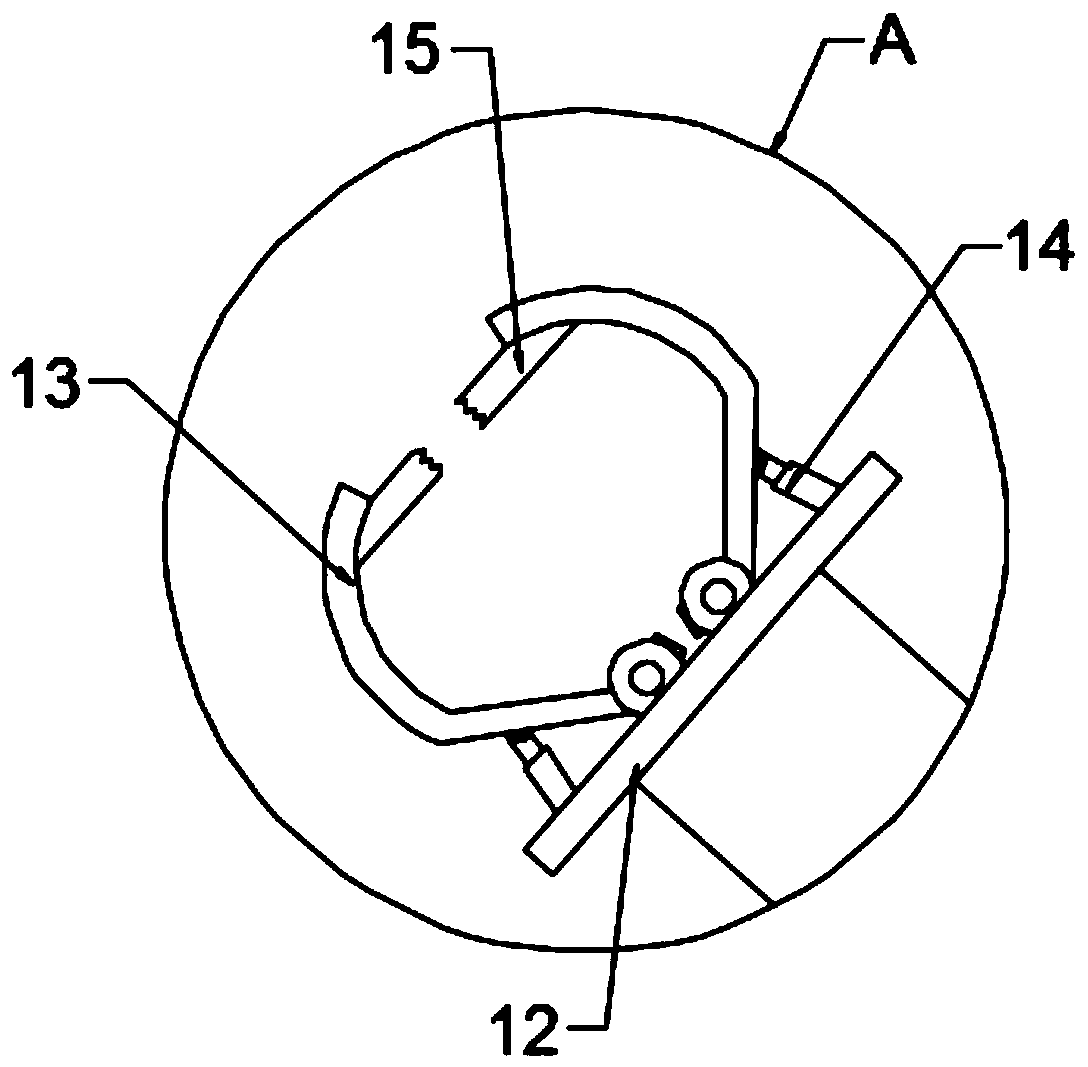

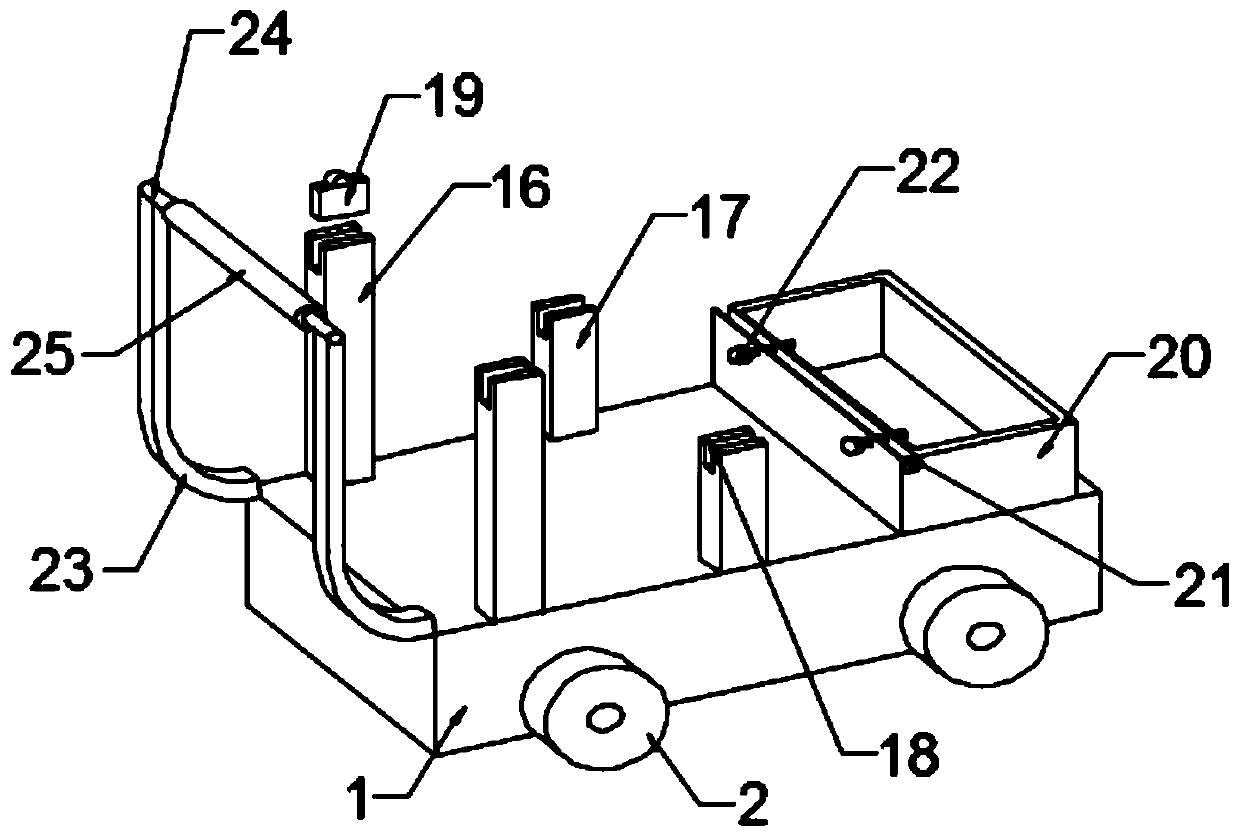

[0043] see Figure 1~2 In one embodiment provided by the present invention, a fruit picking robot for orchards includes a picking table 1 and a driving wheel 2 installed at the bottom of the picking table 1; the upper surface of the picking table 1 is provided with picking Mechanism and collection mechanism; The picking mechanism and the collection mechanism are connected by a buffer mechanism; The picking mechanism includes a drive assembly and a picking assembly; The collection mechanism includes a collection box 26, and the inside of the collection box 26 is provided with a screen Subcomponents.

[0044] The fruit picking robot used in the orchard can pick ripe fruits in the orchard, which not only improves the picking efficiency but also reduces the picking burden of the staff. In addition, the fruit can be screened according to the size, so that the screening and collection of the fruit can be realized.

[0045] In specific use, at first utilize the driving assembly to ...

Embodiment 2

[0057] see figure 1 and Figure 4 In yet another embodiment provided by the present invention, the screening assembly includes at least four screening rollers 29, and both ends of the screening rollers 29 are rotatably mounted in a rotating seat 31, and the rotating seat 31 is fixed on On the inner wall of the collection box 26; the screening rollers 29 are placed obliquely, and the gap between adjacent screening rollers 29 increases successively; the bottom of the collection box 26 is provided with at least three screening frames 30 , the screening frame 30 is located right below the slit.

[0058] The fruit enters the screening assembly through the buffer plate 27, slides down along the inclination angle of the screening roller 29, and is screened in turn according to the size of the fruit. The smallest size slides down from the gap first, and the medium size falls from the second gap. The largest size falls from the last gap. According to the actual situation, the number ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com