Defoaming type stirring device

A stirring device and defoaming technology, which is applied in the direction of mixer accessories, transportation and packaging, foam dispersion/prevention, etc., can solve the problems of low stirring efficiency, slowing down production efficiency, difficulty in continuous and smooth preparation work, etc., and achieve high stirring effect, shorten stirring time, improve collection effect and collection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

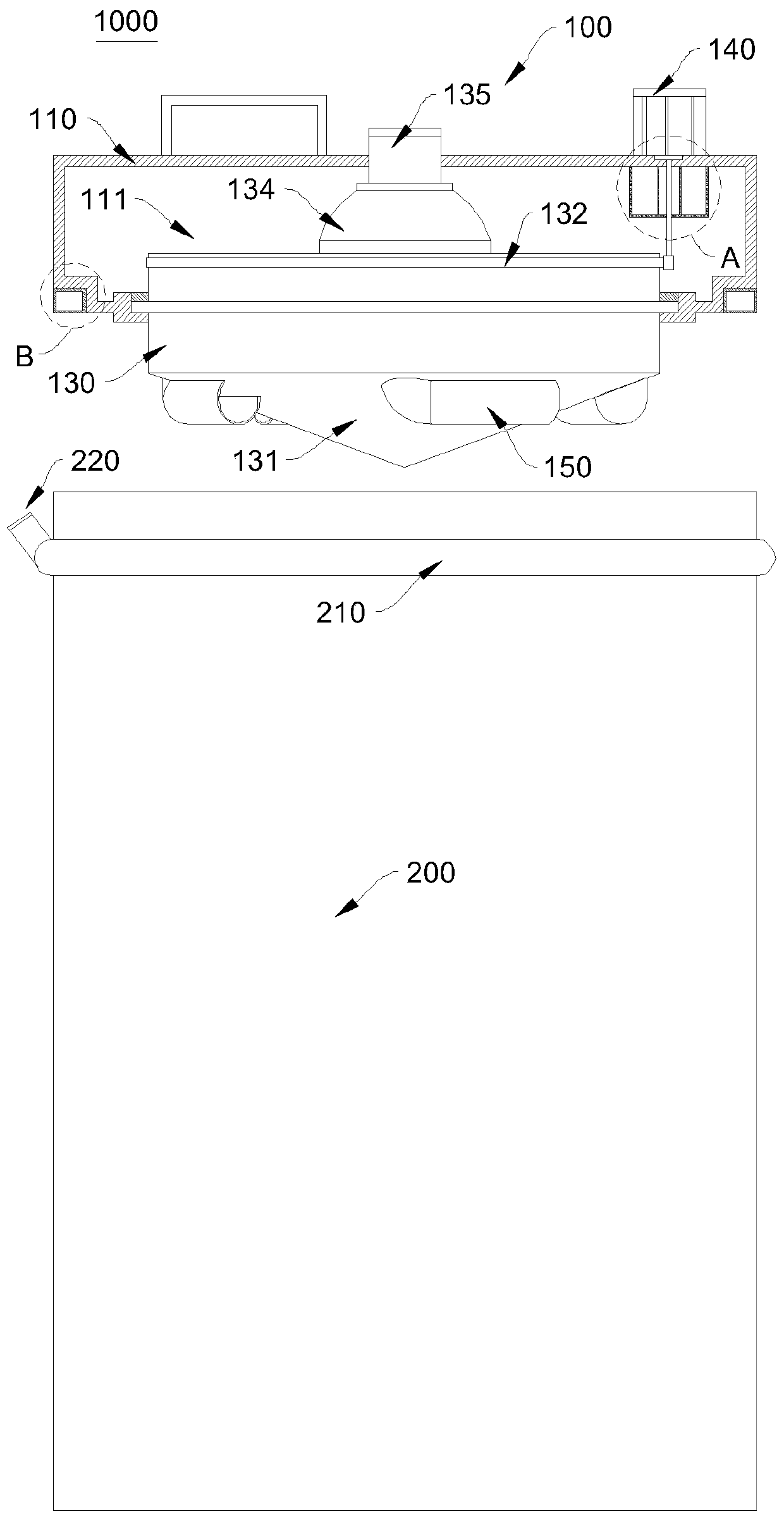

[0037] Please refer to Figure 1~3 , the present embodiment provides a defoaming type stirring device 1000, the defoaming type stirring device 1000 includes: a cover body 100, a barrel body 200, a foam pump (not shown in the figure) and a defoamer (not shown in the figure) .

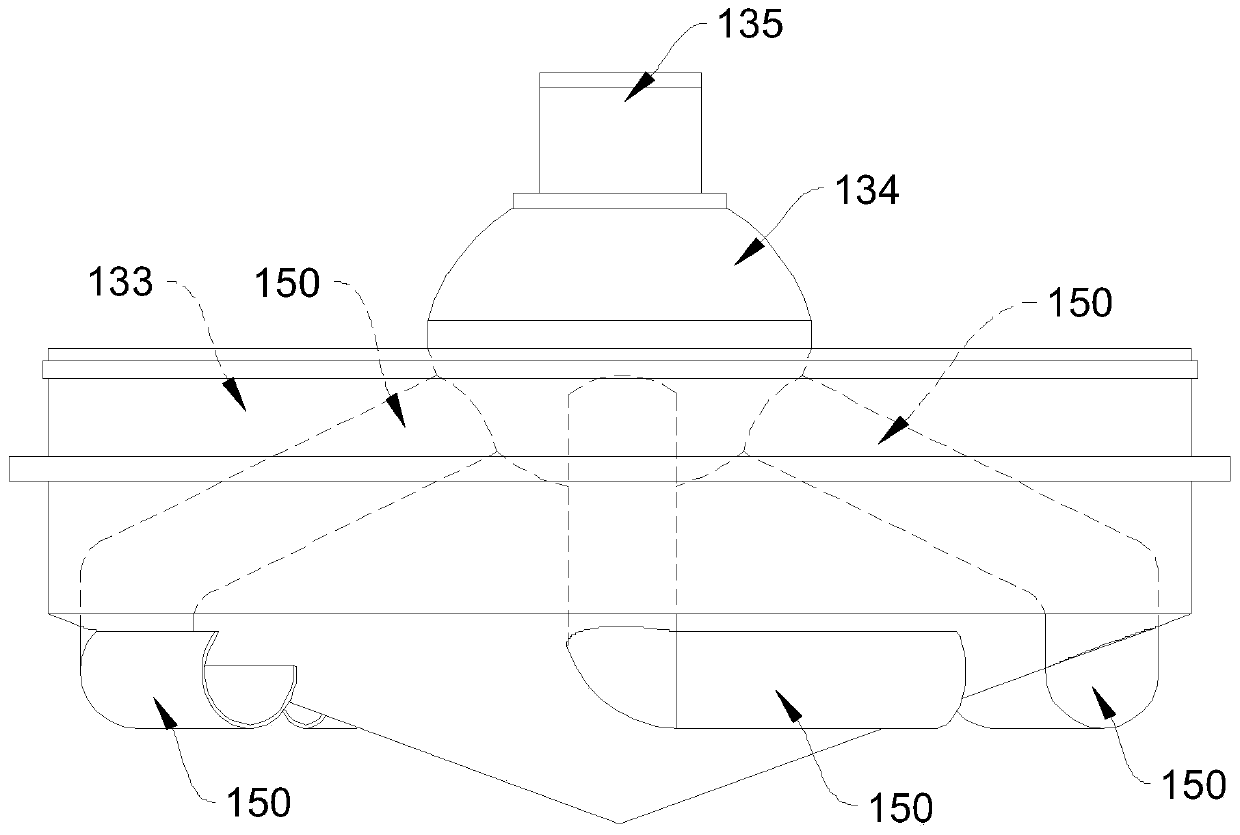

[0038] The cover body 100 is detachably connected with the bucket body 200 , and the cover body 100 includes a cover body 110 , a rotating cylinder 130 and a suction tube 150 .

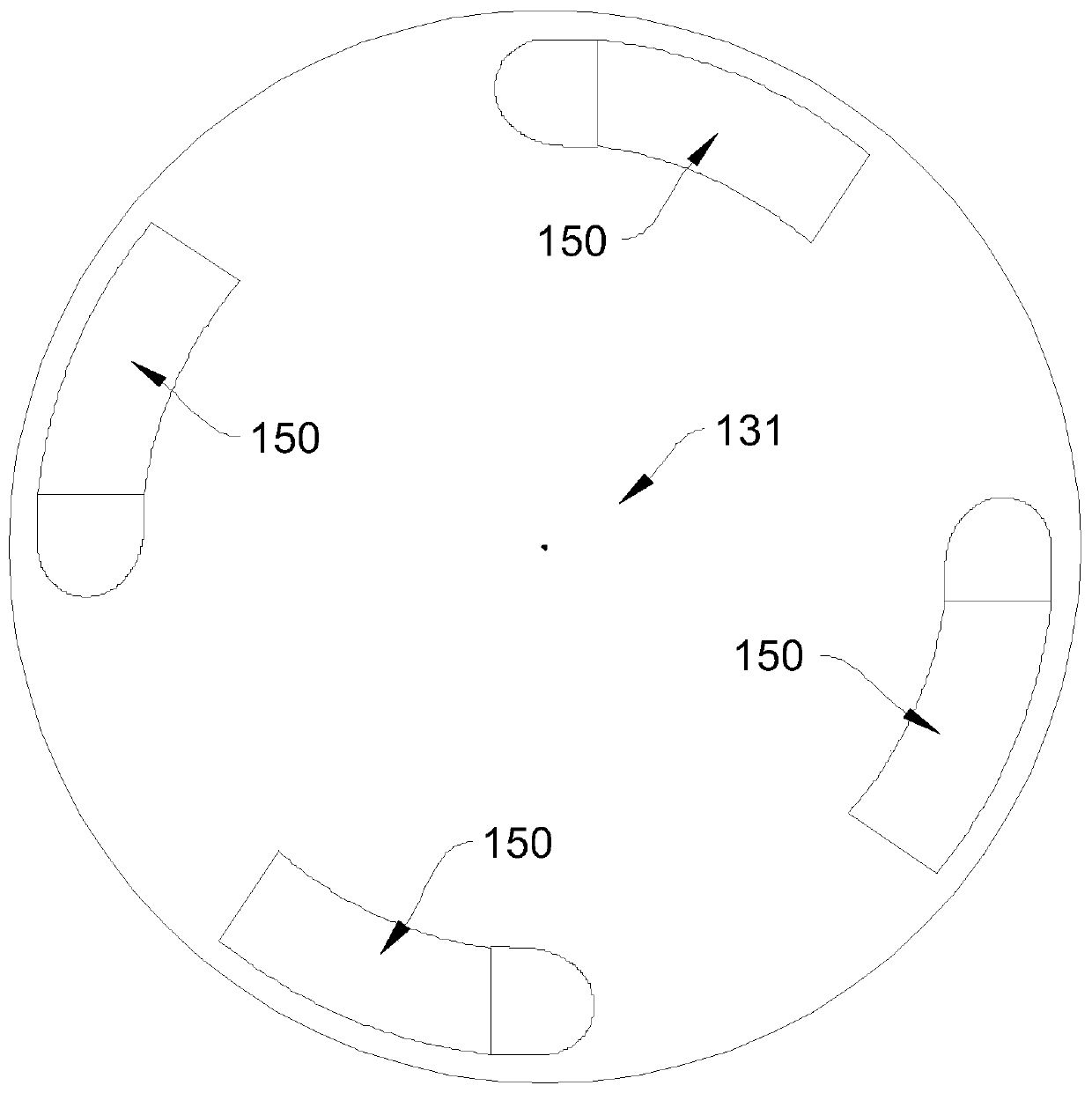

[0039] The rotating cylinder 130 is rotatably embedded in the cover body 110 and driven by the driver 140. The side of the rotating cylinder 130 close to the barrel body 200 protrudes in a conical shape, and the corresponding half top angle is 55-85°. In this embodiment, the corresponding half-vertex angle is set to 70°.

[0040]One end of the suction pipe 150 is attached to the conical wall 131 of the rotating cylinder 130 and extends along the circumferential direction of the conical wall 131. A plurality of suction pipes 15...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com