Positive and negative bidirectional damping mechanism and toilet stool cover plate with same

A technology of two-way damping and damping oil, which is applied in the field of sanitary ware, can solve the problems of misinstallation and misinstallation in the production process, increase the variety of parts, and easily confuse the selection, so as to achieve the effects of reducing the variety of parts, easy standardization, and avoiding misinstallation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0063] The first embodiment (the oil passage of the rotating shaft is controlled by two shift blocks)

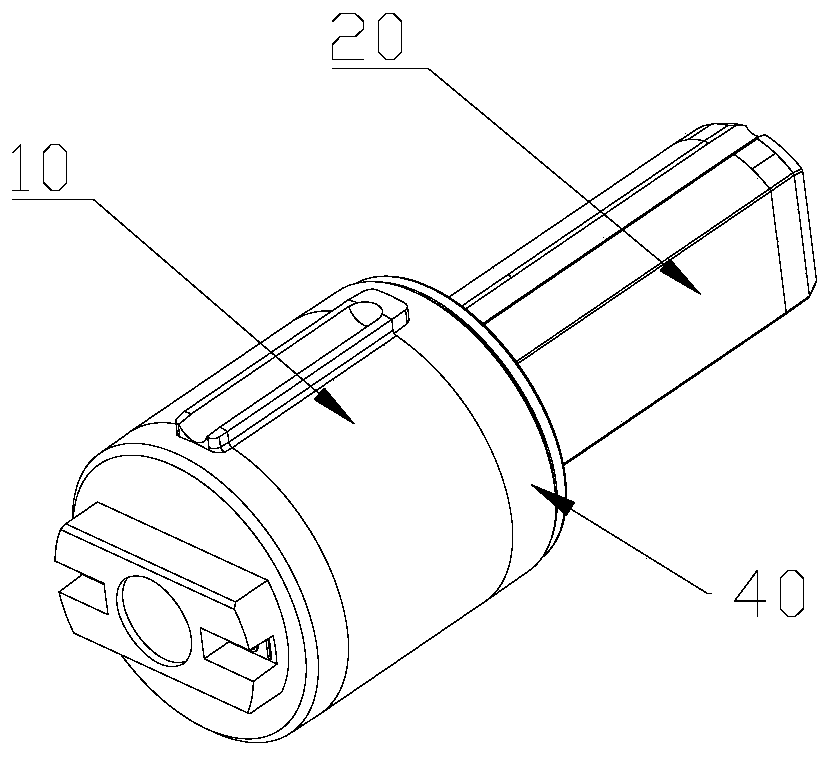

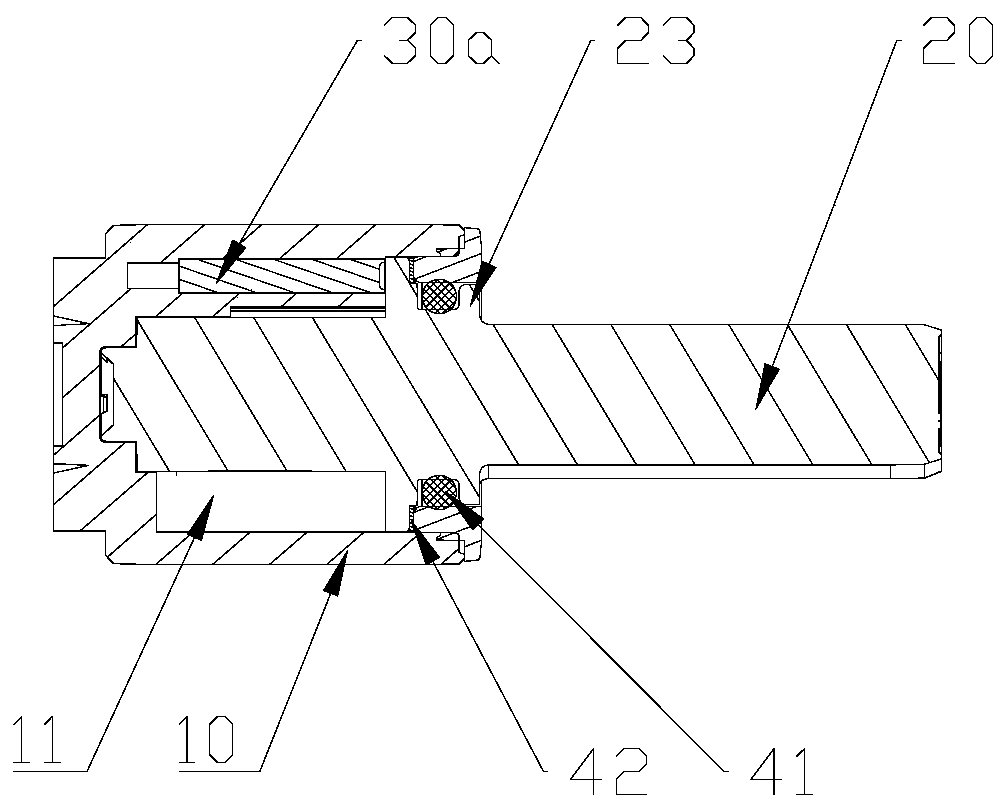

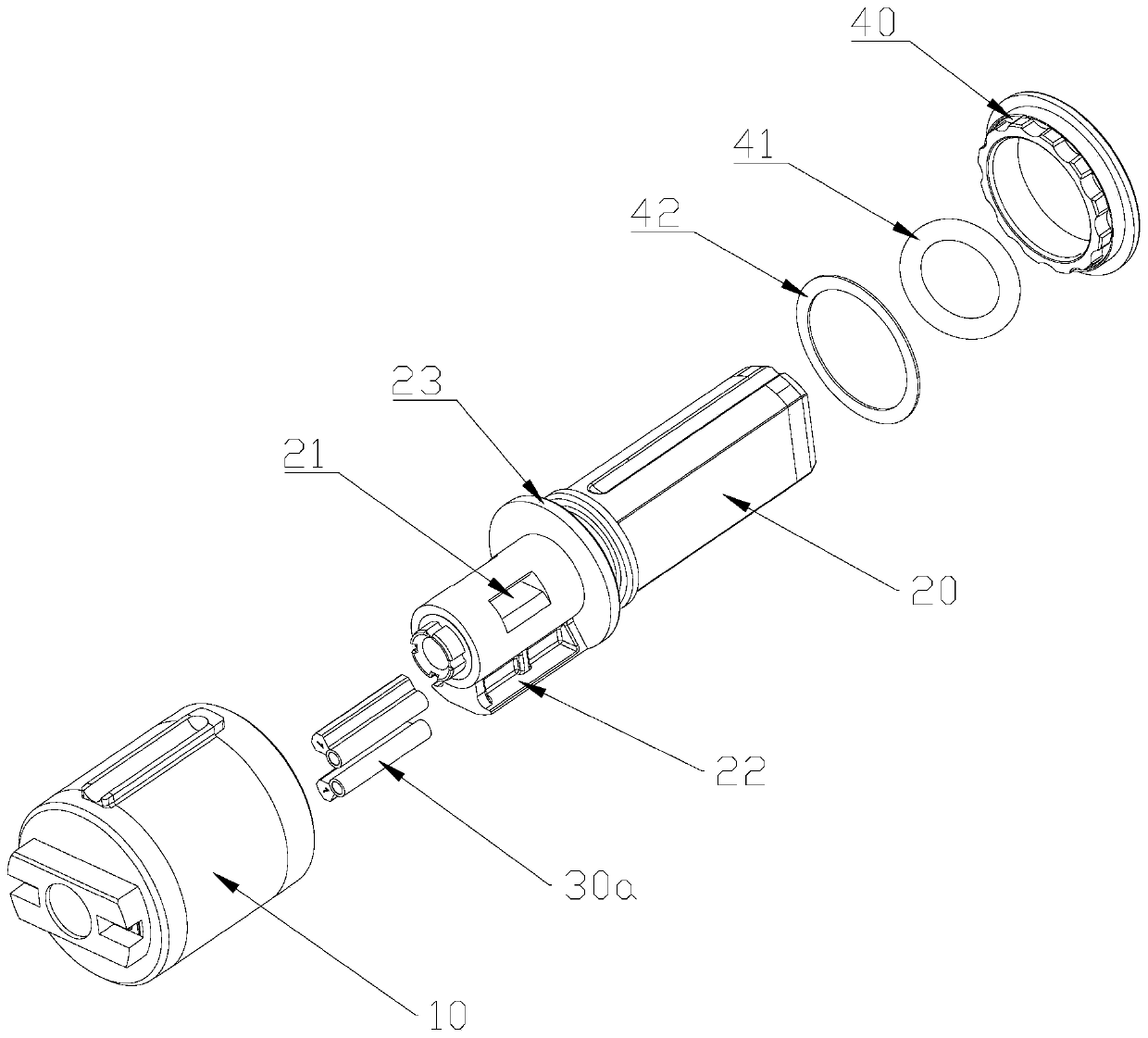

[0064] Such as Figure 1 to Figure 17 As shown, a positive and negative two-way damping mechanism of this embodiment includes a housing 10 provided with an oil chamber 11, a rotating shaft 20 that is sealed and rotated with the oil chamber 11 of the housing 10, and at least one fixedly arranged on the A baffle 22 between the housing (10) and the rotating shaft (20) for disturbing and damping oil, the baffle 22 divides the oil chamber 11 into at least a first oil chamber and a second oil chamber, and It includes a connecting channel 31a connecting the first oil chamber and the second oil chamber. When the rotating shaft 20 rotates clockwise, the baffle plate 22 moves the damping oil in the first oil chamber so that the first oil chamber The damping oil in the oil chamber flows from the connecting passage 31a to the second oil chamber, so that the oil pressure in the first oi...

no. 2 example

[0077] The second embodiment (the oil passage of the rotating shaft is controlled by a shift block)

[0078] Such as Figure 18 to Figure 31 As shown, the main difference between the forward and reverse bidirectional damping mechanism of this embodiment and the first embodiment is that: in this embodiment, the shifting block includes one, and the shifting block includes a first end and a second end; When the rotating shaft 20 rotates clockwise from the initial position, the first end of the shift block cooperates with the housing 10 to reduce the flow cross-section at one end of the connecting passage; when the rotating shaft 20 rotates counterclockwise from the initial position , the second end of the shifting block cooperates with the housing 10 to reduce the flow cross-section of the other end of the connecting channel 31b.

[0079] Other embodiments can also be used, when the rotating shaft 20 rotates clockwise from the initial position, the first end of the shift block c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com