Garbage can

A trash can and vacuum pump technology, applied in the field of trash cans, can solve the problems of overfilled items, items that cannot be closed, unable to tie the mouth, etc., and achieves the effect of facilitating the closing of the bag body, the effect is good, and the breakage rate is reduced.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

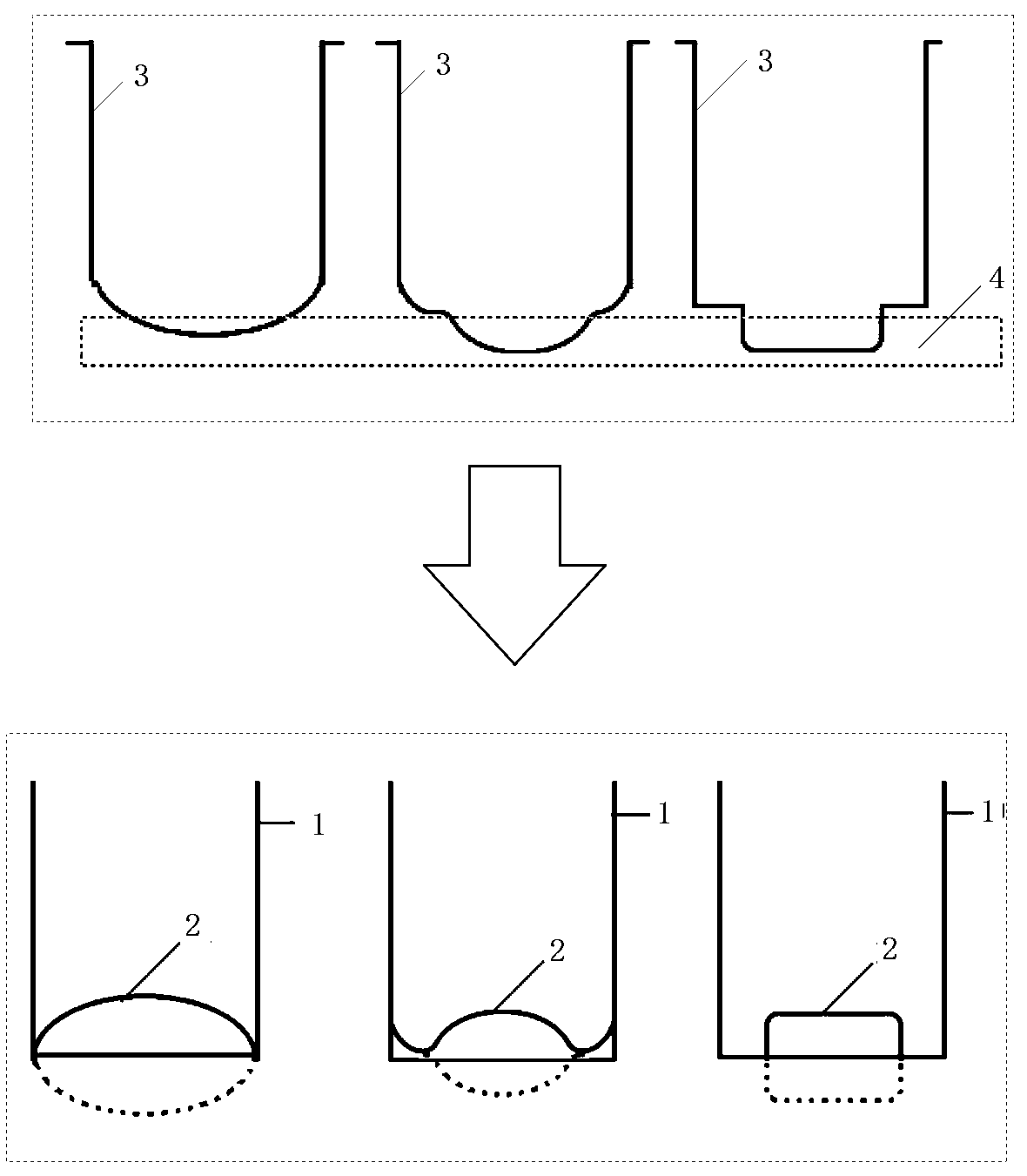

[0024] The bottom of the storage cavity of the garbage 1 is provided with an upwardly protruding volume preparation area 2 . The volume reserve area 2 is used to temporarily occupy the available volume of the bag body 3 put into the trash can. When the bag body 3 is full of items and then raised, the bag body 3 is lifted up, and the available volume occupied by the bag body 3 (volume reserve area 4) is released after leaving the volume reserve area 2, and the overfull items fall back after release , so that it is convenient for the bag body 3 to close or reduce the possibility of items being spilled.

[0025] Such as figure 1 As shown, the shape of the volume preparation area 2 can be varied. The protrusion of the volume preparation area 2 should be understood as having a shape higher than the sides. Higher than the two sides, it will drop down at the bulge when the volume is released, and the volume release is about twice that of the volume reserve area.

[0026] The siz...

Embodiment 2

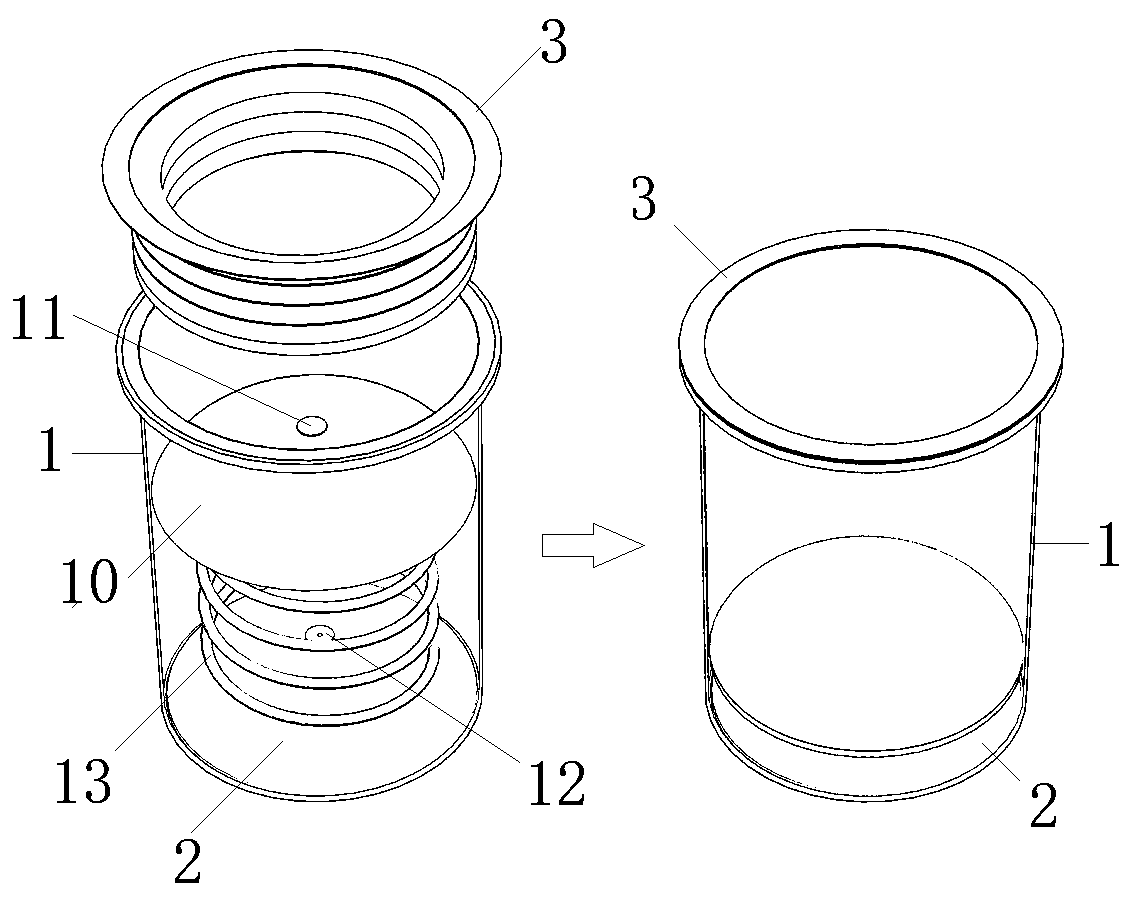

[0028] In this embodiment, on the basis of Embodiment 1, the trash can is provided with a bag feeding mechanism. The types and installation positions of the bag feeding mechanism are diverse, and this embodiment discloses the following types:

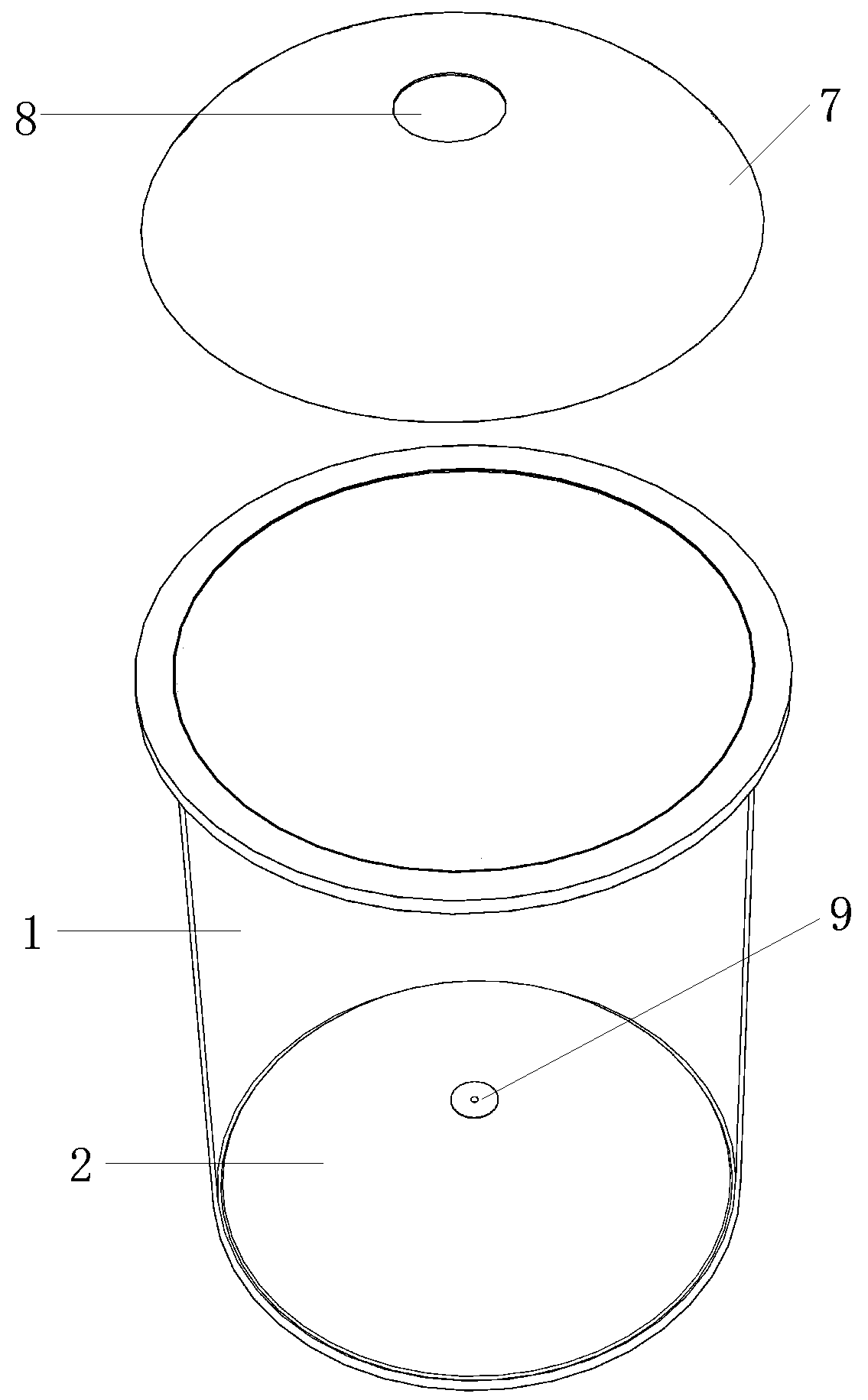

[0029] 1. If figure 2 As shown, the bag feeding mechanism is a push plate mechanism.

[0030] The push plate mechanism includes a push plate 7 that is transitionally matched with the opening of the trash can; the push plate 7 is matched with the volume reserve area 2; the push plate 7 is provided with an air hole 8 that penetrates up and down; The A one-way exhaust valve 9 leading to the outside world; the push plate 7 is loosely connected to the bottom or the side wall of the garbage can 1. When in use, the bag body 3 can be pushed into the trash can 1 by using the push plate 7, and the bag body 3 is close to the trash can 1 as much as possible. The function of the air hole 8 is to make the space between the push plate 7 and the bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com