A kind of preparation method of whole process alkaline synthetic urea-formaldehyde resin wood adhesive

A technology for synthesizing urea-formaldehyde resins and wood adhesives, which is applied in the fields of adhesives, adhesive types, aldehyde/ketone condensation polymer adhesives, etc., and can solve problems that have not been reported and cannot be synthesized with urea-formaldehyde resins.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

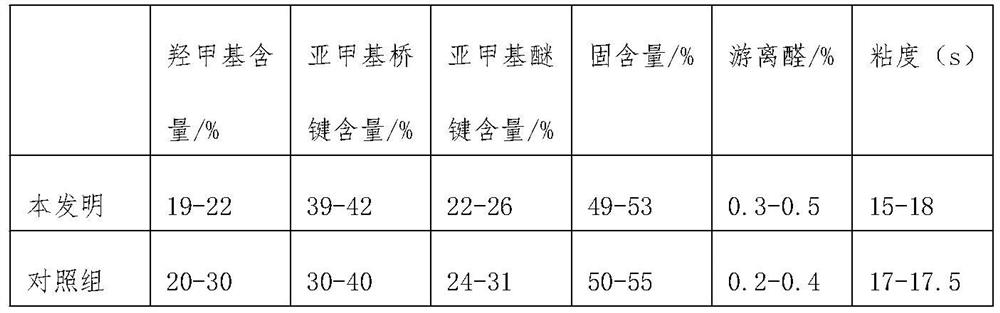

Image

Examples

Embodiment 1

[0026] A kind of preparation method of whole course alkaline synthetic urea-formaldehyde resin wood adhesive:

[0027] (1) Add the first metered formaldehyde solution into the reaction kettle, adjust the pH value to 7.5-9.0; add the first urea under stirring, control the molar ratio of formaldehyde to urea at 1.0, and then gradually raise the temperature of the reactant to 90-95°C; the stirring speed is 1500r / min;

[0028] (2) After heat preservation and reaction at 90-95°C for 30 minutes, cool down to 80-85°C, adjust the pH value to 9.0-10.0 with a compound base, add the second formaldehyde solution, and control the molar ratio of formaldehyde to urea is 1.8;

[0029] (3) Add a batch of formaldehyde at 80-85°C for every 30 minutes of heat preservation reaction until the molar ratio of formaldehyde to urea is 2.0, adjust the pH value to 10.0-11.0, then raise the temperature to 90-95°C, keep warm React for 90 minutes;

[0030] (4) Cool down to 70-80°C, adjust the pH value to...

Embodiment 2

[0033] A kind of preparation method of whole course alkaline synthetic urea-formaldehyde resin wood adhesive:

[0034] (1) Add the first metered formaldehyde solution into the reaction kettle, adjust the pH value to 7.5-9.0; add the first urea under stirring, control the molar ratio of formaldehyde to urea at 1.2, and then gradually raise the temperature of the reactant to 90-95°C; where the stirring speed is 2000r / min;

[0035] (2) After heat preservation and reaction at 90-95°C for 60 minutes, lower the temperature to 80-85°C, adjust the pH value to 9.0-10.0 with a compound base, add the second formaldehyde solution, and control the molar ratio of formaldehyde to urea in 1.8;

[0036] (3) At 80-85°C, add a batch of formaldehyde after every 30 minutes of heat preservation reaction until the molar ratio of formaldehyde to urea is 2.1, adjust the pH value to 10.0-11.0, then raise the temperature to 90-95°C, keep warm React for 90-180 minutes;

[0037] (4) Cool down to 70-80°...

Embodiment 3

[0040] A kind of preparation method of whole course alkaline synthetic urea-formaldehyde resin wood adhesive:

[0041] (1) Add the first metered formaldehyde solution into the reaction kettle, adjust the pH value to 7.5-9.0; add the first urea under stirring, control the molar ratio of formaldehyde to urea at 1.4, and then gradually raise the temperature of the reactant to 90-95°C; the stirring speed is 3000r / min;

[0042](2) After heat preservation and reaction at 90-95°C for 90 minutes, cool down to 80-85°C, adjust the pH value to 9.0-10.0 with a compound base, add the second formaldehyde solution, and control the molar ratio of formaldehyde to urea in 2.0;

[0043] (3) At 80-85°C, add a batch of formaldehyde after every 30 minutes of heat preservation reaction until the molar ratio of formaldehyde to urea is 2.2, adjust the pH value to 10.0-11.0, then raise the temperature to 90-95°C, keep warm React for 180 minutes;

[0044] (4) Cool down to 70-80°C, adjust the pH value...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com