Detecting level performing mechanism

A technology of actuators and deceleration mechanisms, which is applied in the field of torque monitoring structures, can solve the problems that the actuators cannot be integrated, and achieve the effects of light weight, reduced detection links, and reduced equipment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention more clear, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

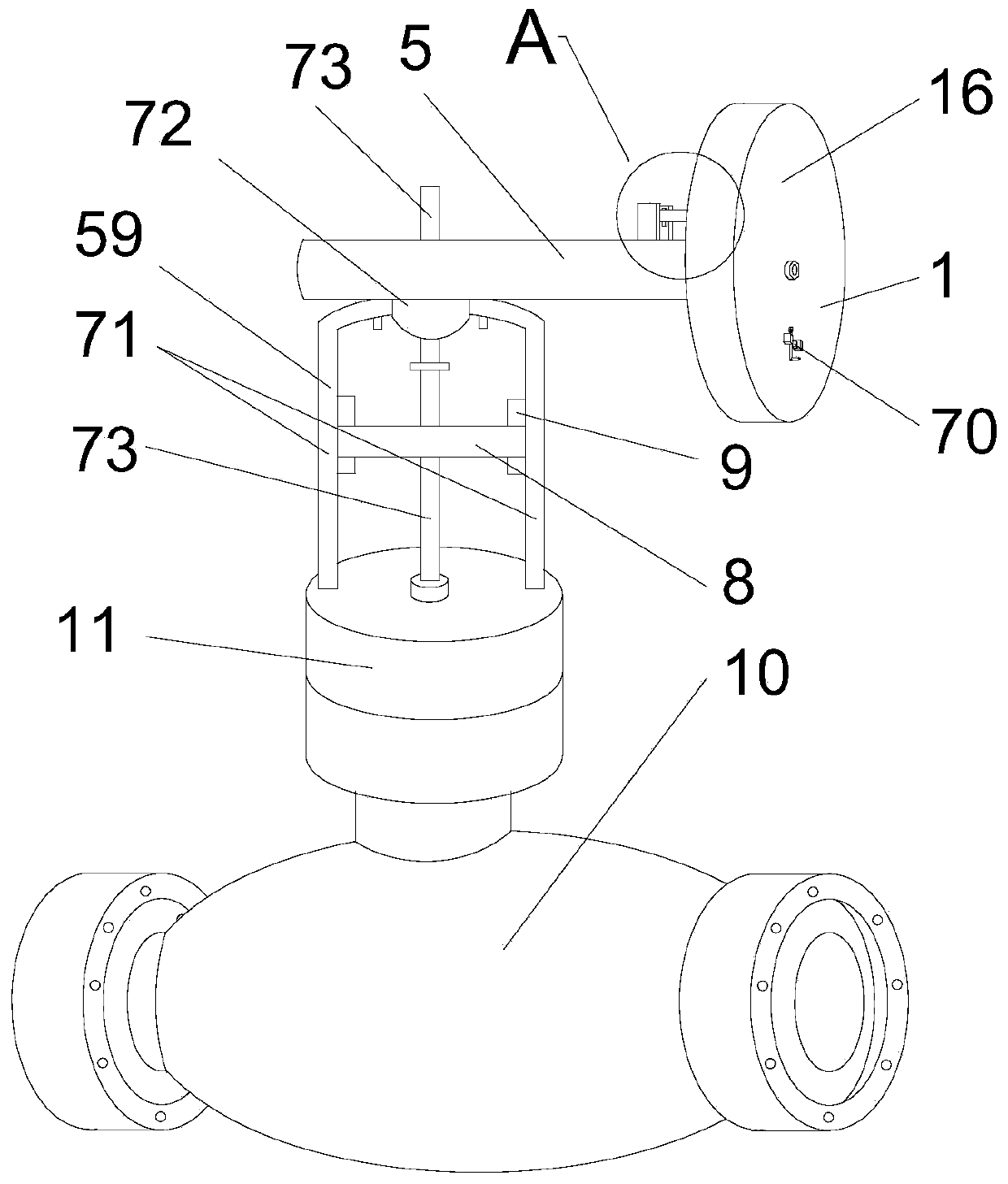

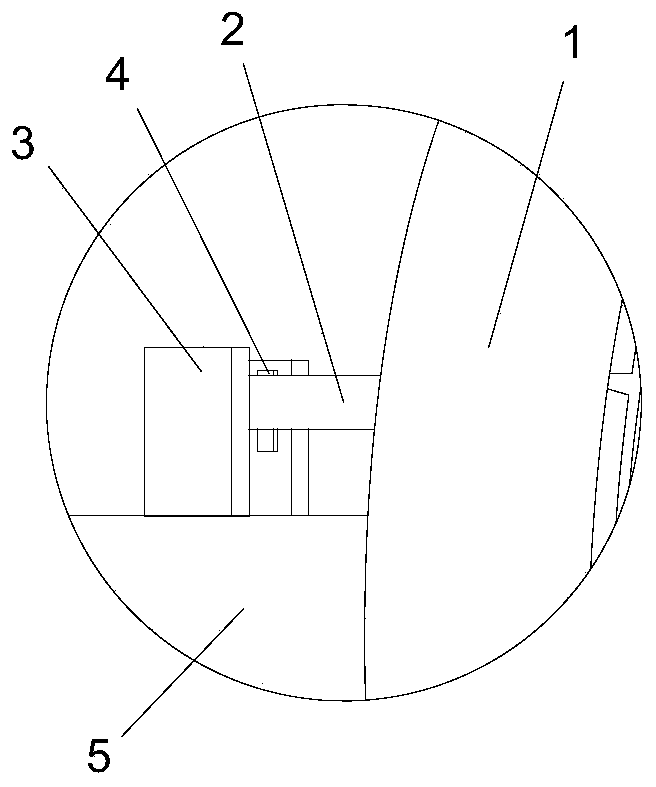

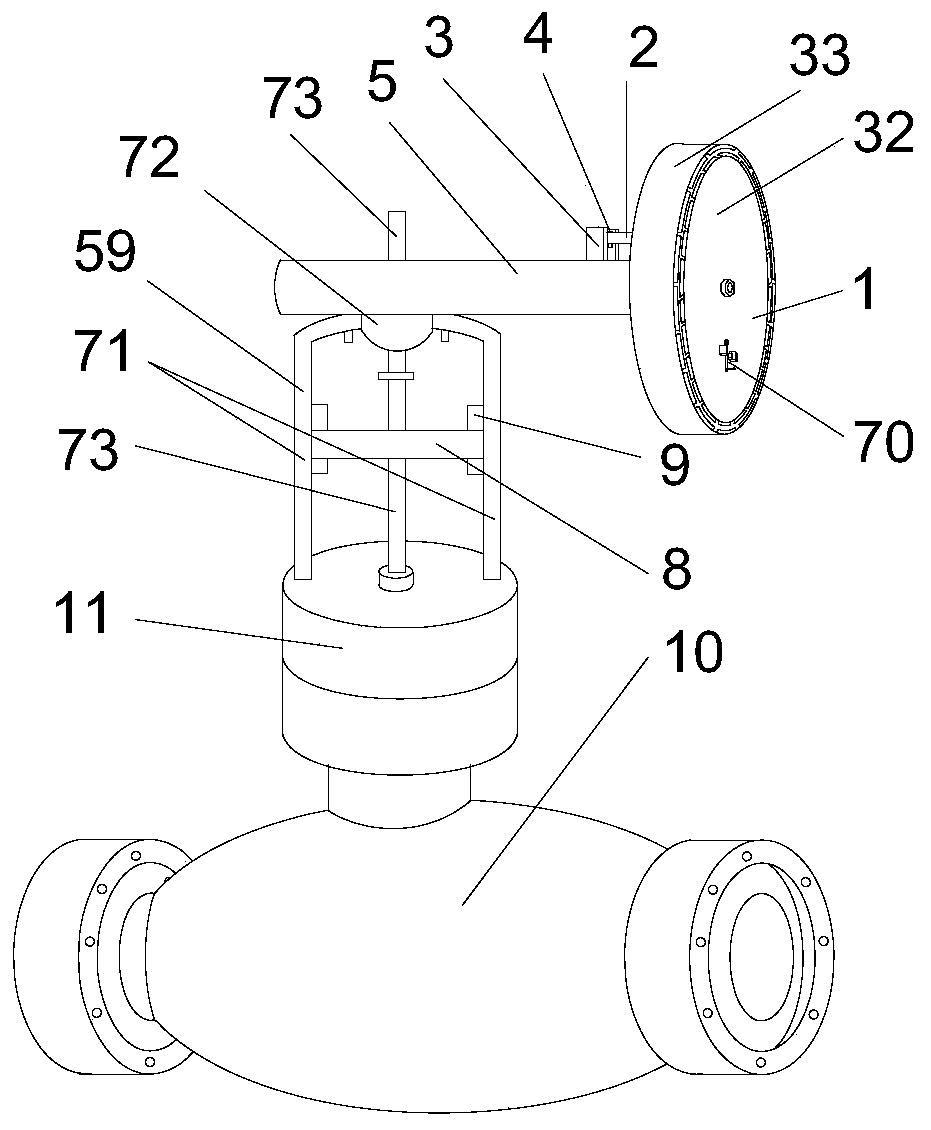

[0020] like Figure 1 to Figure 15 , Figure 17 to Figure 22 , Figure 24 , Figure 25 , Figure 28 , Figure 30 and Figure 31 As shown, the present invention provides a detection level actuator, the first detection mechanism includes: motor 1, screw rod, valve rod or input shaft of reduction mechanism, sensor 4, stator anti-rotation device 2 and control device 3, display and control device 12; wherein the motor 1 includes a rotor and a stator; as Figure 7 , Figure 8 , Figure 9 , Figure 13 As shown, the motor 1 includes a rotor and a stator, the center of the rotor has a hollow shaft 22, the center of the hollow shaft 22 has a special-shaped hole 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com