Cable block detection device

A technology for detecting devices and bales, which is applied in the direction of measuring devices, mechanical measuring devices, mechanical devices, etc., and can solve problems such as difficult disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

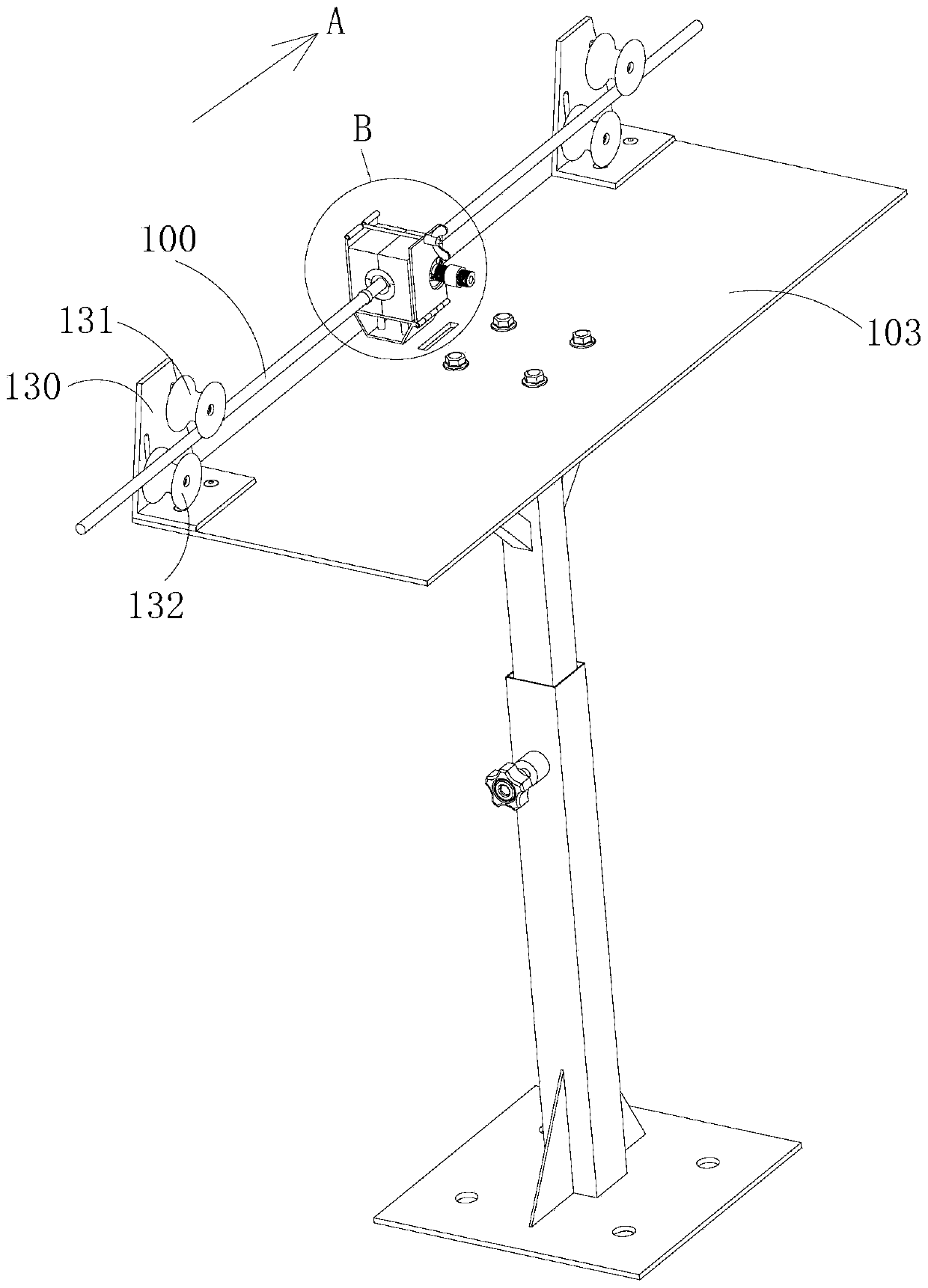

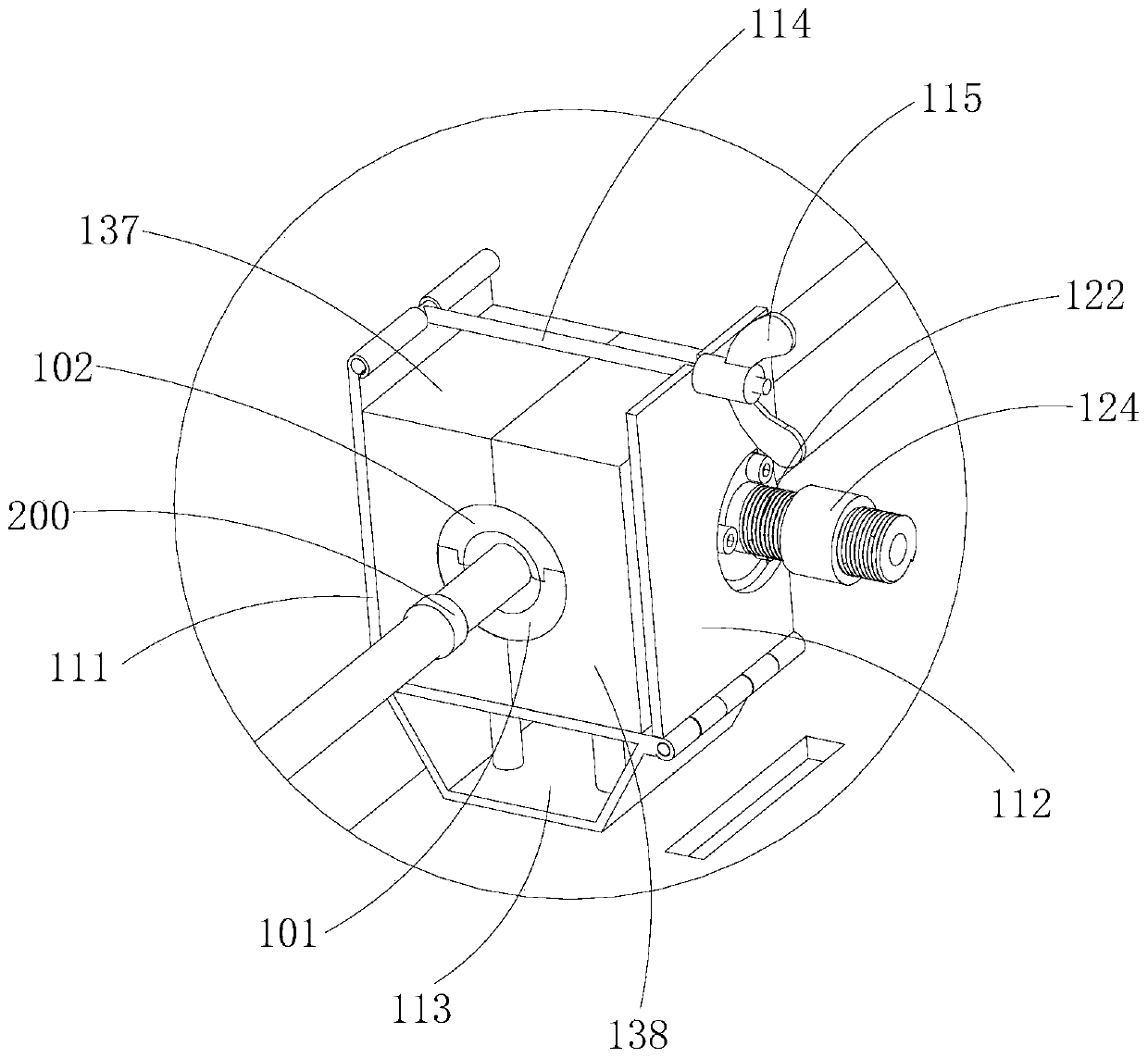

[0049] see Figure 1 to Figure 12 As shown, among them, figure 1 The arrow direction A in the figure refers to the moving direction of the cable 100. During the moving process, the position where the cable 100 passes first is defined as "front". In order to clearly describe the technical solution of this embodiment, figure 1 The cable 100 to be tested is shown in . This embodiment provides a cable package detection device, including a fixing device and a wire passing mold, the fixing device is provided with a limit hole for placing the wire passing mold; the wire passing mold includes a first half mold 101 and a second half mold 102, the first half-mold 101 and the second half-mold 102 are placed in the limit holes, and can be fastened to form a channel 106 for the cable 100 to pass through; when the width d of the package 200 on the surface of the cable is larger than the channel When the width w of 106, the package block 200 can be in contact with the front end faces of t...

Embodiment 2

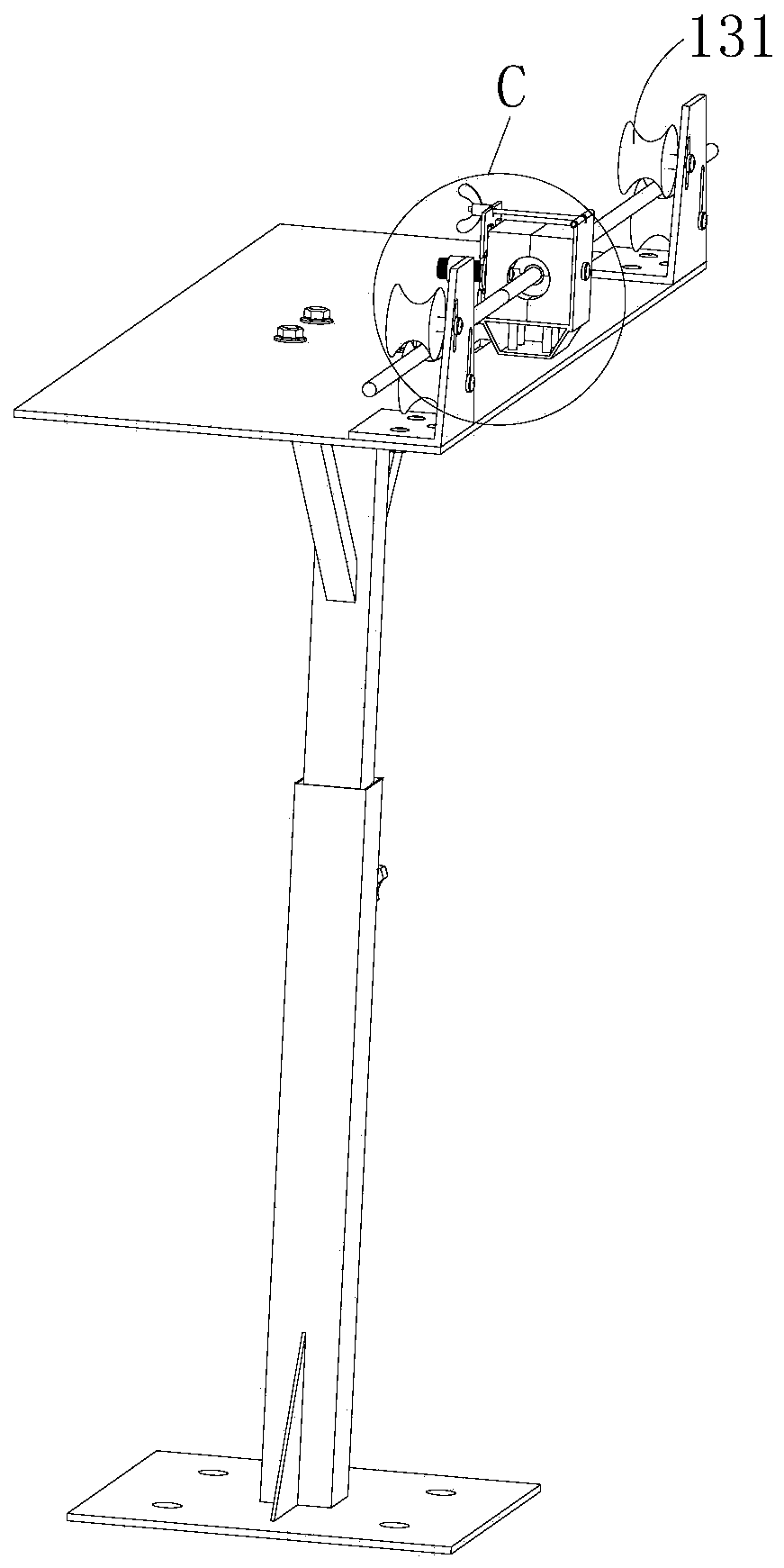

[0094] see Figure 13 and Figure 14 As shown, this embodiment also provides a cable packet detection device. The cable packet detection device of this embodiment is an improvement on the basis of Embodiment 1. In addition, the technical solution of Embodiment 1 It also belongs to this embodiment and will not be described again here. The same components use the same reference numerals as in the first embodiment, and reference is made to the description of the first embodiment.

[0095] In order to be able to detect lumps in time and prevent the lumps from being entangled on the take-up reel as the cables move, the cable lump detection device provided in this embodiment also includes an alarm device. The alarm device includes a gap adjustment seat 135, a first reset switch S1, transmission rod 136, magnetic latching relay J and alarm L; one end of gap adjustment seat 135 is connected with elastic force adjustment seat 124, and the first reset switch S1 is installed on the oth...

Embodiment 3

[0104] see Figure 15 and Figure 16 As shown, this embodiment also provides a cable bundle detection device. The cable bundle detection device in this embodiment describes another connection method between the first clamping block 137 and the second clamping block 138. In addition The other technical solutions of Embodiment 1 also belong to this embodiment, and will not be described again here. The same components use the same reference numerals as in the first embodiment, and reference is made to the description of the first embodiment.

[0105] In some embodiments, the first clamping block 137 is provided with a first connecting portion, the second clamping block 138 is provided with a second connecting portion, and the first connecting portion is fixedly connected to the second connecting portion.

[0106] In a possible implementation, the first connecting part is the first mounting plate 141, the first mounting plate 141 is fixedly connected to the upper surface of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com