Tobacco sheet physical property prediction mode establishment method

A technology of tobacco sheet and physical properties, which is applied in the fields of tobacco, tobacco processing, food science, etc., can solve the problem of not being able to quickly evaluate the physical properties of tobacco sheets, and achieve the effects of online regulation, saving production costs, and saving testing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0028] Tobacco sheets from 7 different manufacturers were collected, and the samples were flexibly decomposed to obtain a fiber suspension. An appropriate amount of fiber suspension was used for fiber analysis with a fiber quality analyzer, and the tensile index was measured according to GB / T12914-2008. The results are shown in Table 1.

[0029] Table 1 Fiber morphology index and longitudinal tensile index of seven different tobacco sheets

[0030]

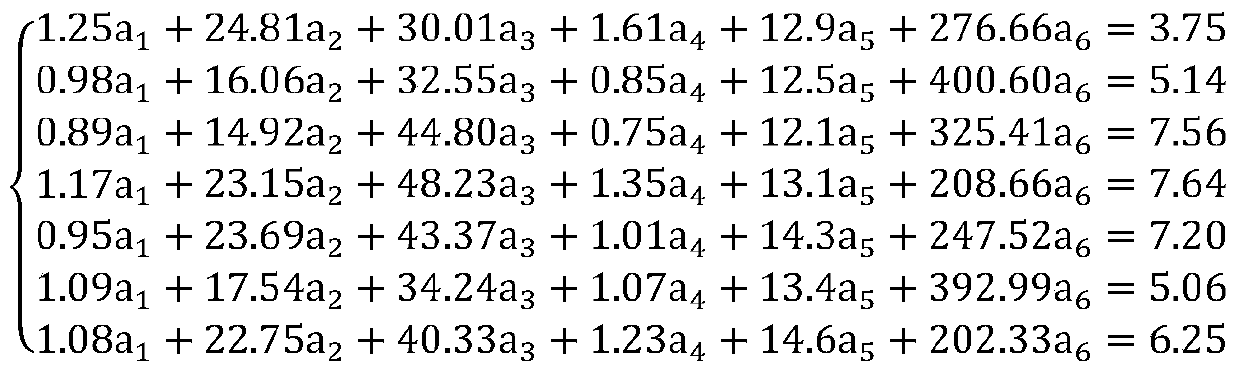

[0031] The linear equations obtained from Table 1 are as follows:

[0032]

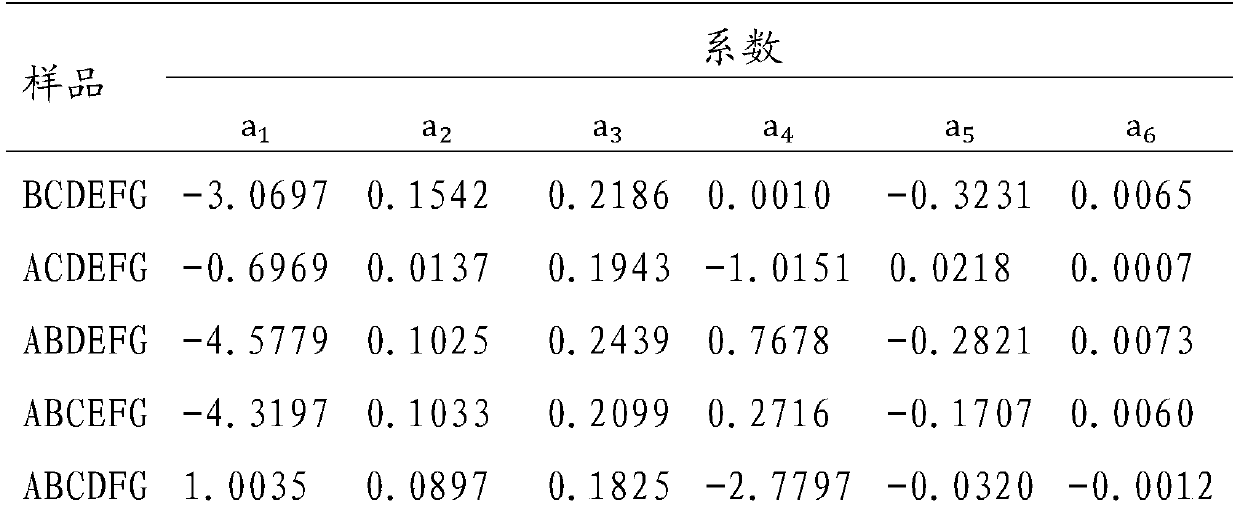

[0033] Randomly select 6 equations to form a one-variable linear equation system, and solve their independent variable coefficients. The results are shown in Table 2. shown.

[0034] Table 2 Results of longitudinal tensile index prediction model

[0035]

[0036]

[0037] The prediction equation is obtained as follows:

[0038]

[0039] Substitute the parameters of the seventh sample into the obtained model to calculate the relative err...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap