Method and device used for regulating and controlling large and small bubble fractal structures to enhance mass transfer

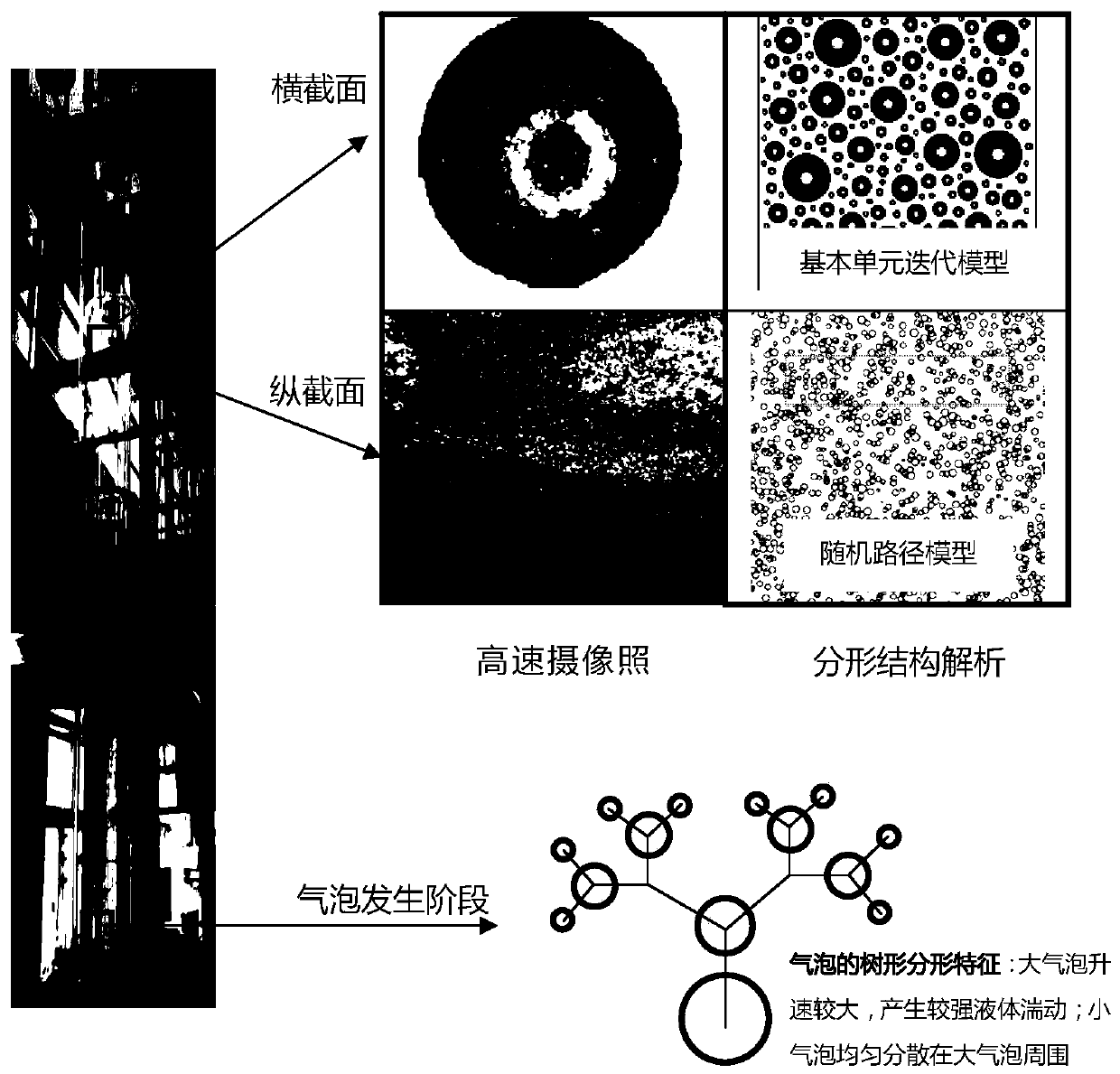

A technology of fractal structure and large bubbles, which is applied in chemical methods, chemical instruments and methods for reacting liquid and gaseous media, and the reaction of liquids and gases under foam/aerosol/bubbles, etc., which can solve obstacles to reactor optimization and the progress of development, the inability to give further details of the bubbles, and the inability to effectively count and analyze the bubble shape of the gas-liquid reactor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0045] Example 1

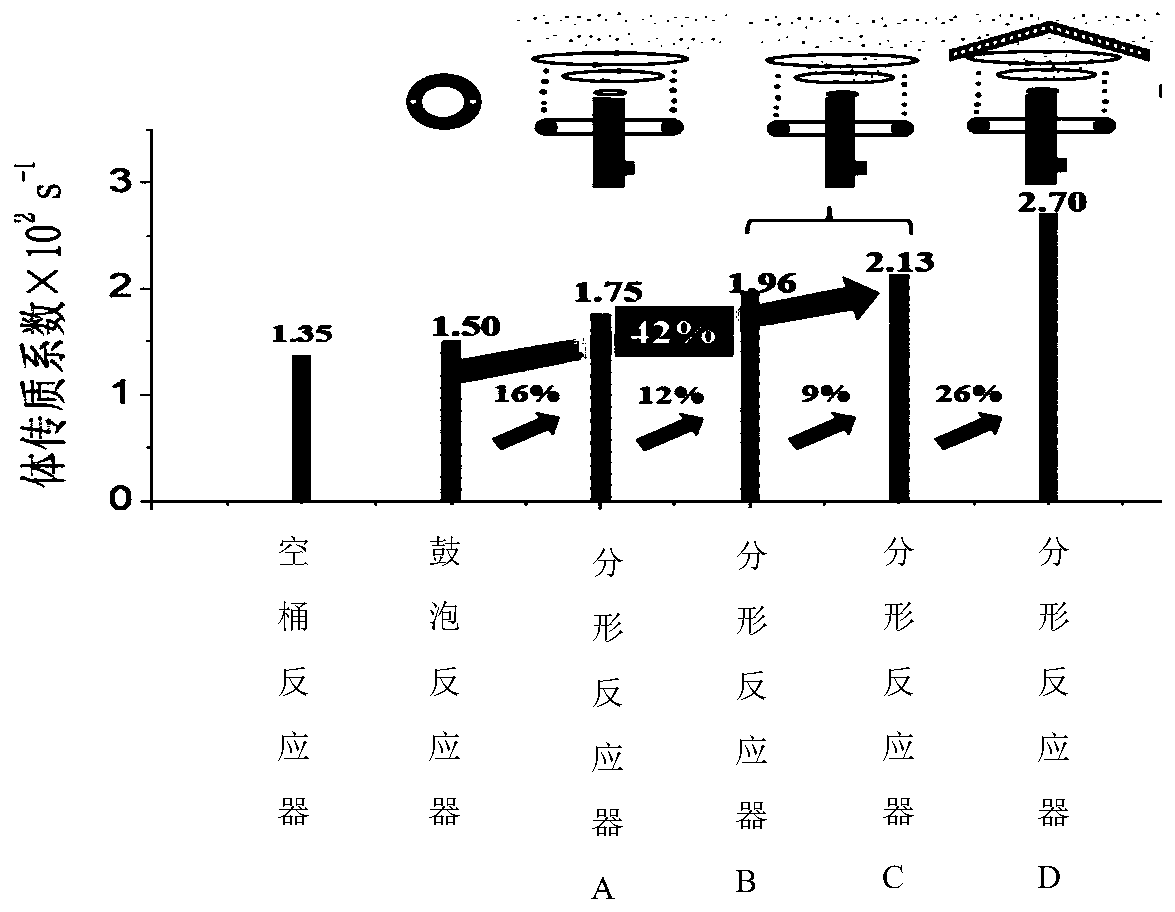

[0046] In a reactor with a diameter of 180 mm and a height of 2.2 meters, the oxygen mass transfer experiment was carried out, and the traditional bubbling reactor and the fractal bubble reactor were used for comparative analysis, such as: figure 1 As shown, all are gas-liquid upflow flow state, the apparent gas velocity is 0.025m / s, the apparent liquid velocity is 0.0077m / s, the experimental temperature is 15 degrees Celsius, the dynamic oxygen concentration method is used to measure KLa, the bulk mass transfer coefficient like figure 2 shown. When the method and device are used to dissolve oxygen in water, the mass transfer coefficient is increased from 0.015 to 0.027.

Example Embodiment

[0047] Example 2

[0048] In a reactor with a diameter of 280 mm and a height of 6 meters, the oxygen mass transfer experiment was carried out, and the traditional bubbling reactor and the fractal bubble reactor were used for comparative analysis. All are in the gas-liquid upflow state, the apparent gas velocity is 0.005-0.025m / s, the apparent liquid velocity is 0.0077m / s, and the experimental temperature is 15 degrees Celsius. The dynamic oxygen concentration method is used to measure KLa. The mass transfer coefficient is as follows: figure 2 shown. When the method and device are used to dissolve oxygen in water, the mass transfer coefficient of the traditional bubbling reactor is 0.0025-0.013, and the mass transfer coefficient of the reactor F with a reasonable fractal dimension is 0.013-0.026. Under the working condition of 0.025m / s, the bulk mass transfer coefficient is increased to twice that of the bubbling reactor.

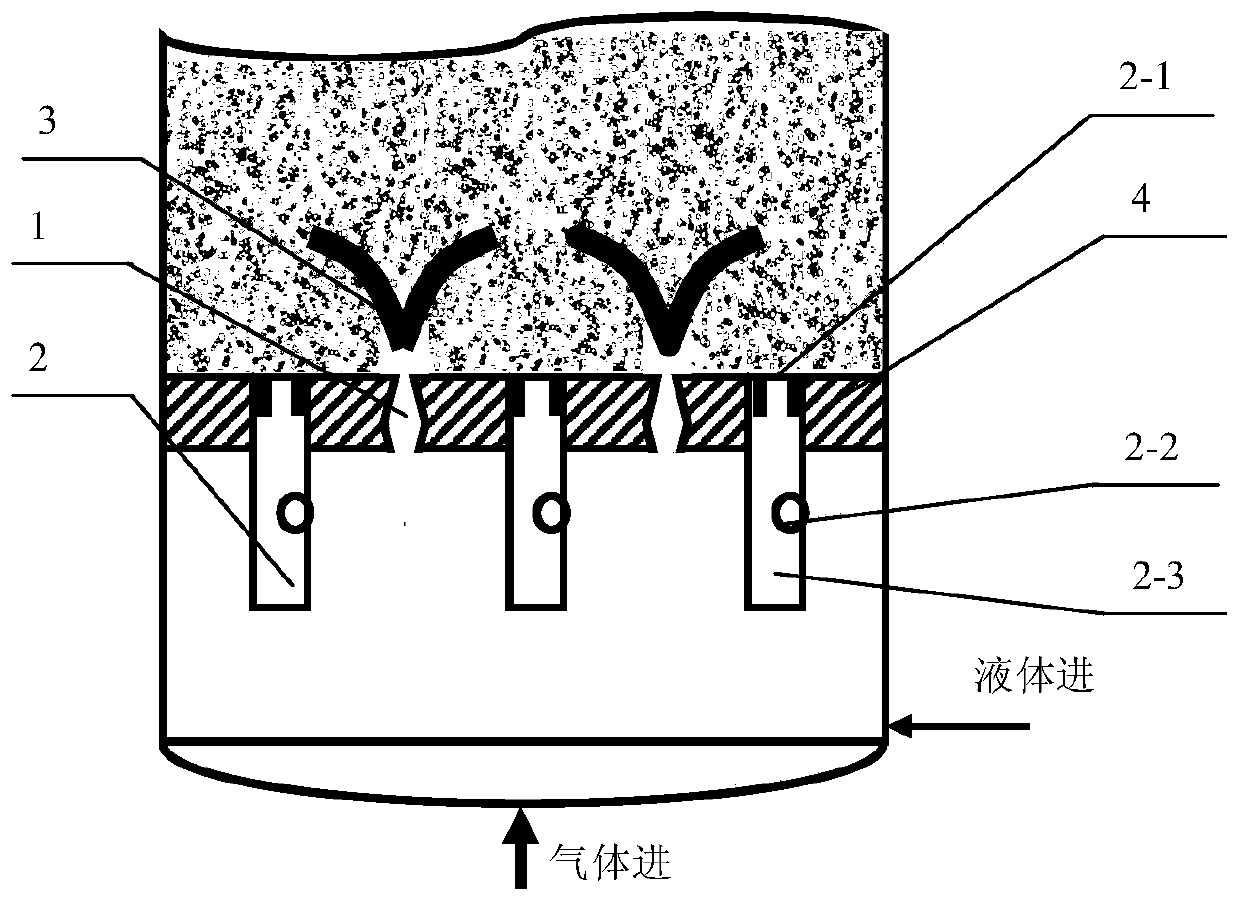

[0049] like image 3 Schematic diagram of the dis...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap