Upper reinforcing assembly for vehicle body B pillar

A technology for strengthening components and B-pillars, which is applied to vehicle components, superstructures, and sub-assemblies of the superstructure, and can solve problems such as uneven paths, large body deformation, and difficulty in opening doors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

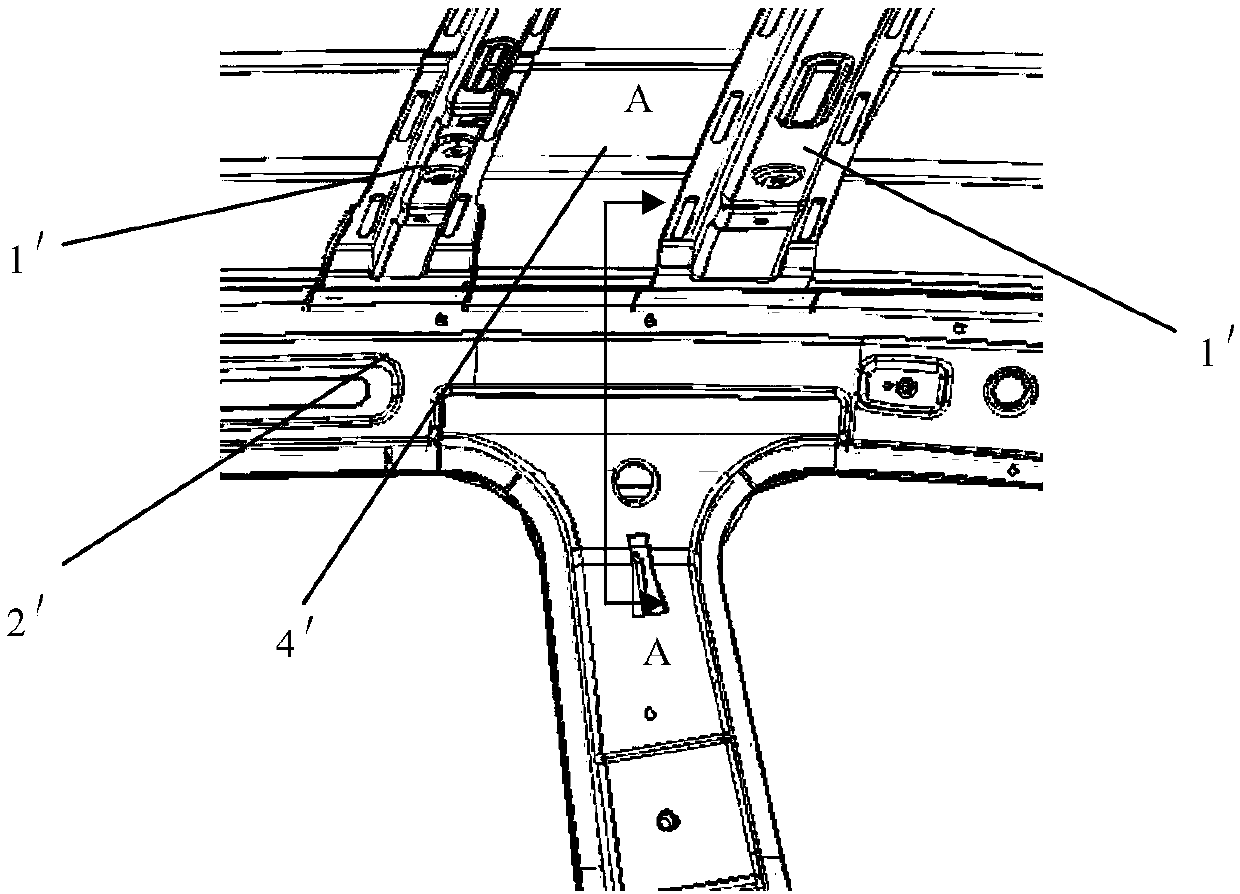

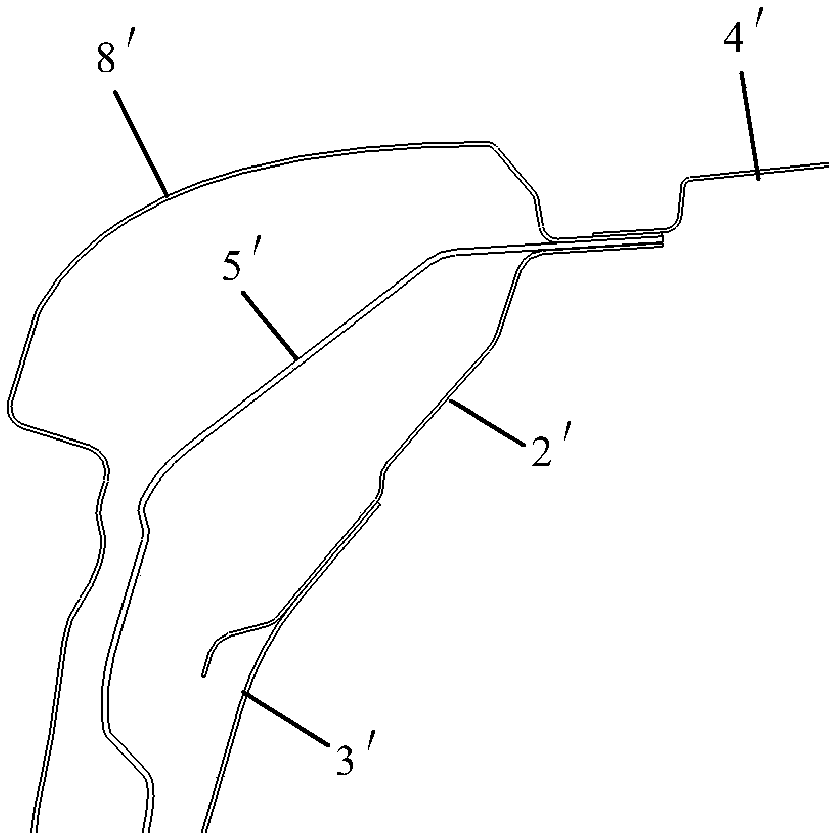

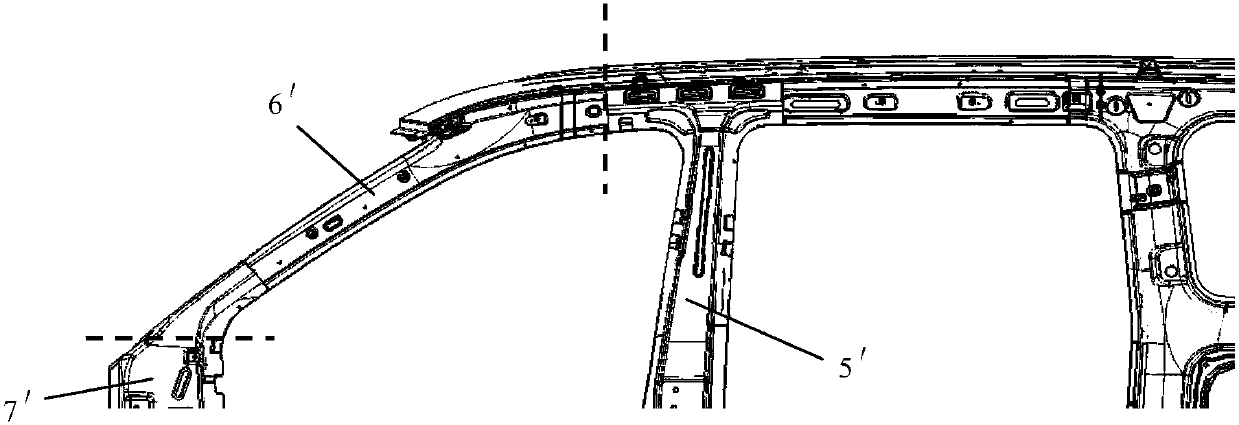

[0033] The following with attached Figure 4 to Figure 9 A B-pillar upper reinforcement assembly of a vehicle body of the present invention is further described in detail.

[0034] A kind of vehicle body B-pillar upper reinforcement assembly of the present invention, please refer to Figure 4 to Figure 9As shown, it includes a B-pillar inner panel 3, a top beam 1, a B-pillar connecting plate 4, an upper side sill inner panel 2 and an A-pillar upper reinforcement panel 5, and the side part of the upper side sill inner panel 2 is laterally extended and fixed on the B-pillar Inside the upper end of the pillar inner panel 3, the A-pillar upper reinforcement plate 5 extends laterally and is fixed on the inner side of the upper side sill inner panel 2, the roof beam 1 is longitudinally fixed on the top cover 17, and the end of the roof beam 1 is connected to The upper end of the B-pillar inner panel 3 is fixed, the upper end of the B-pillar connecting plate 4 is fixed to the head o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com