Cable winding drum under condition of high-frequency high-speed winding and unwinding

A cable reel, high-speed technology, used in the field of cable reels, can solve the problems of large fluctuations in cable tension due to impact torque, and achieve the effect of ensuring normal cable retraction and prolonging service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below according to the accompanying drawings and specific examples.

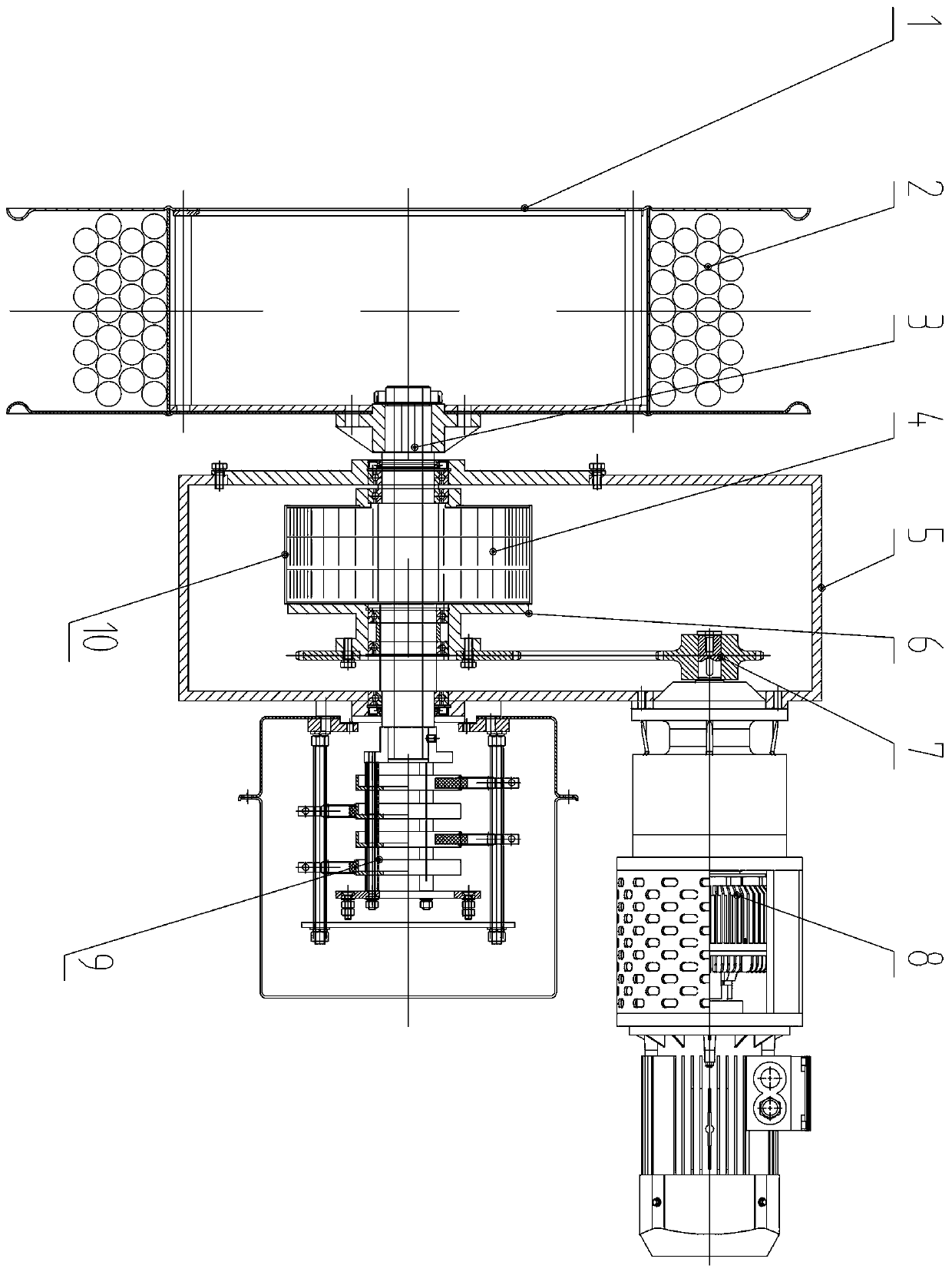

[0019] Depend on figure 1 It can be seen that the present invention is mainly composed of a reel 1, a cable 2, a reduction box 5, a vortex spring 4, a drive unit 8, and a conductive slip ring box 9. The drive unit 8 adopts a hysteresis coupling drive, a hydraulic coupling drive or a variable frequency motor, etc. Flexible drive system. The drive unit 8 is connected to the reduction box 5 through bolts, the gear or sprocket 7 is installed on the output shaft of the drive unit, and is connected to the flange 6 in the reduction box through gear transmission or chain transmission, and the flange 6 is connected to the vortex spring cover 10 Through bolt connection, the inner hook and outer hook of the scroll spring are respectively connected with the spring cover 10 and the output shaft 3 of the reduction box. The output shaft 3 of the reduction box has a fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com