A method and device for repairing underwater hollowing defect of ship lock navigation wall pile foundation on gravel layer foundation

A defect repair and gravel layer technology, applied in infrastructure engineering, sheet pile walls, buildings, etc., can solve the problems of infeasibility, high cost and uneconomical underwater manual foundation clearing, and achieve simple and economical construction and huge safety benefits. And economic benefits, anti-tao effect effect is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

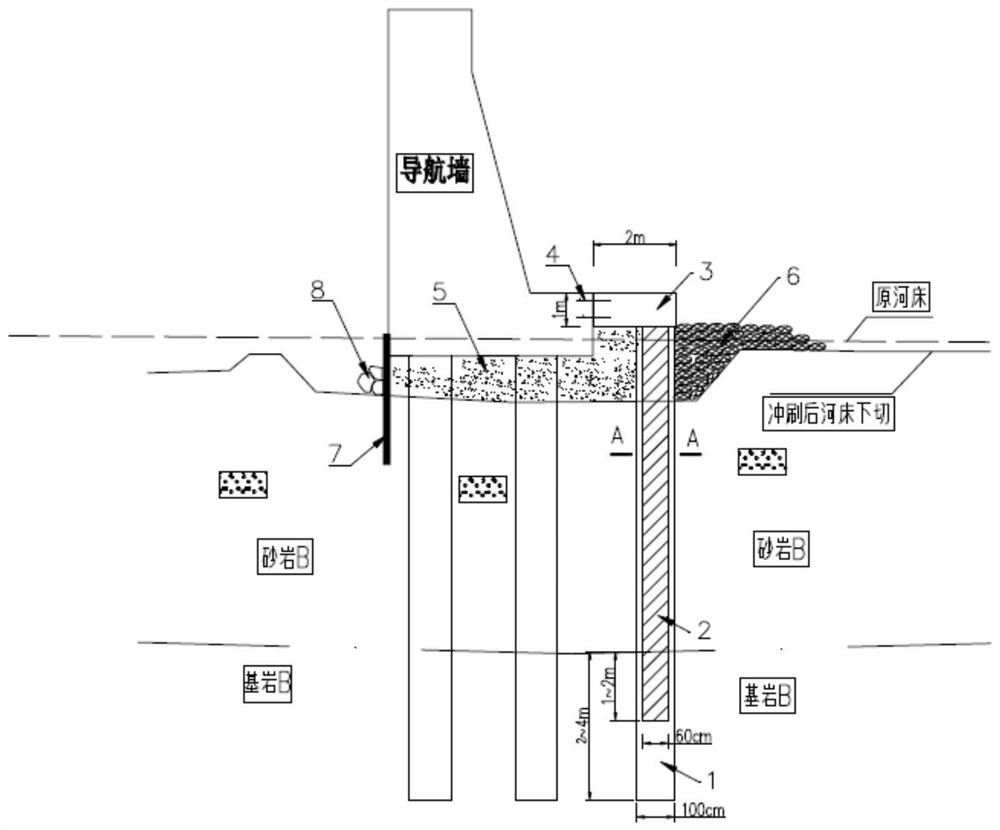

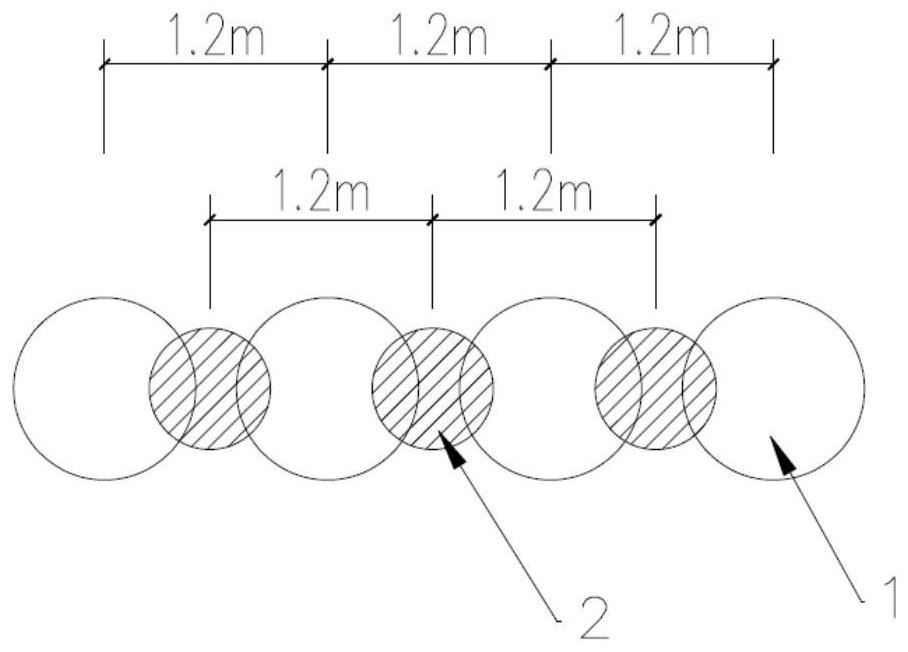

[0027] Such as figure 1 As shown, an underwater hollowing defect repair device for ship lock navigation wall pile foundation on gravel layer foundation, including anti-seepage concrete pouring pile 1, plain concrete pile 2, concrete connecting beam 3, planting reinforcement 4 and non-dispersive concrete filler 5 . 1 row of anti-seepage concrete pouring piles is arranged at 2m outside the water-facing surface of the underwater hollowing defect of the navigation wall pile foundation, and a row is arranged along the outer edge of the navigation wall. 1 pile is 2-4m deep into the bedrock, the anti-seepage concrete pouring pile 1 is made of C30 concrete, the pile diameter is 100cm, and the distance between the anti-seepage concrete pouring piles 1 is 120cm. The plain concrete pile 2 is poured between the anti-seepage concrete pouring piles 1 as a ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap