Local reinforcing method for concrete silo

A local reinforcement and concrete technology, which is applied in building maintenance, building types, buildings, etc., can solve the problems of large force, and achieve the effect of reasonable structure, reduced bearing capacity and uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

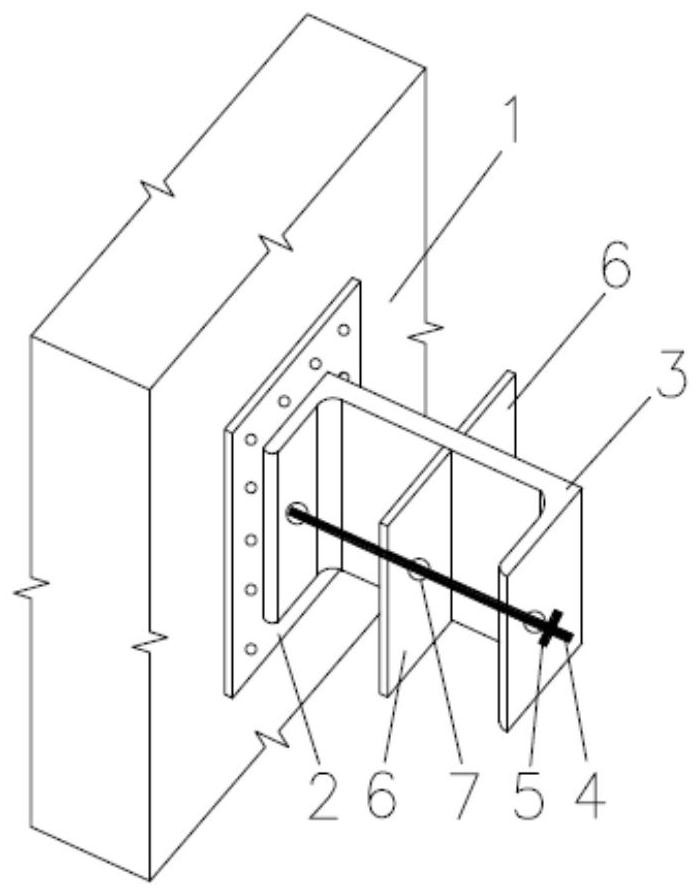

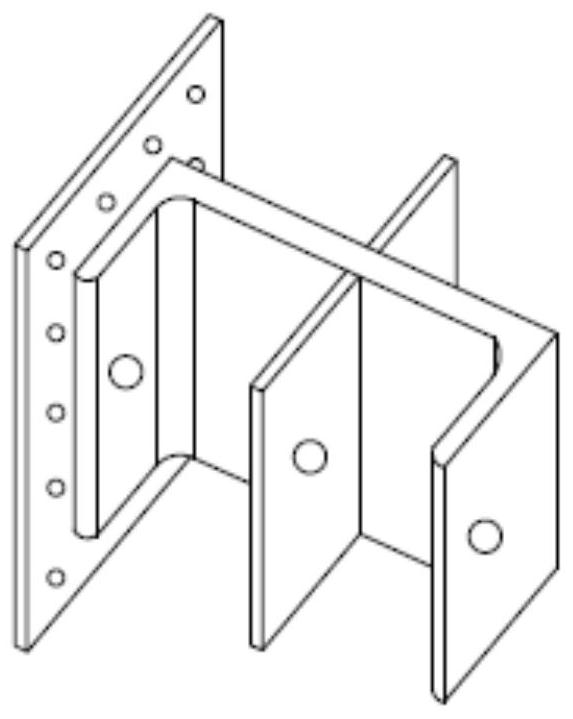

[0031] Such as figure 2 Among them, a row of bolt holes 7 is set on the U-shaped support frame 3 and the reinforcement plate 6, and the high-strength bolts 4 pass through the bolt holes 7 on the U-shaped support frame 3 and the reinforcement plate 6 from the outside to the inside, and the bolts are located on the U-shaped support frame. 3. A jacking nut 5 is arranged on the outer part; the high-strength bolt 4 makes its front end press against the steel backing plate 2, and at the same time, the jacking nut 5 is turned outward, so that the jacking nut 5 is tightened outward against the U-shaped support frame 3, And a certain prestress is applied to the steel backing plate 2 .

Embodiment 2

[0033] Such as image 3 Among them, two rows of bolt holes 7 are set on the U-shaped support frame 3 and the reinforcing plate 6, and the two rows of screw holes 7 are arranged at equal vertical intervals. The high-strength bolts 4 pass through the bolt holes 7 on the U-shaped support frame 3 and the reinforcement plate 6 from the outside to the inside, and set the tightening nuts 5 on the parts outside the U-shaped support frame 3; the high-strength bolts 4 make the front end tighten The steel backing plate 2 is rotated outwardly at the same time the clamping nut 5, so that the clamping nut 5 is pressed against the U-shaped support frame 3 outwardly, and a certain prestress is applied to the steel backing plate 2.

Embodiment 3

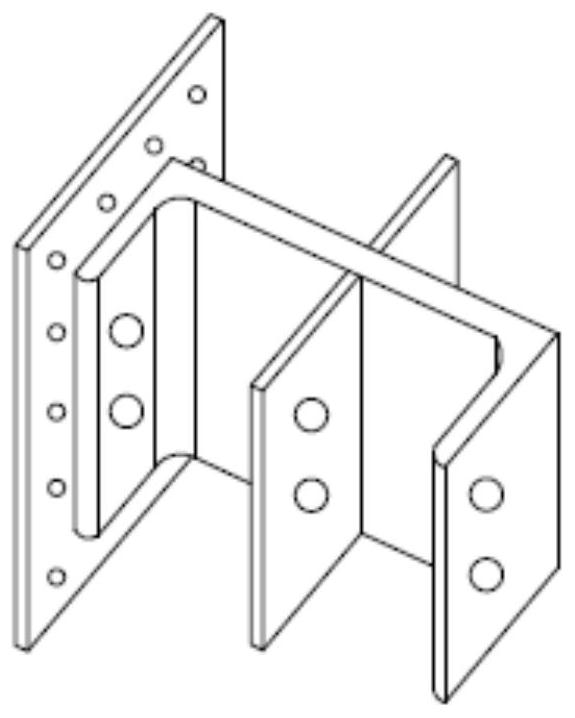

[0035] Such as Figure 4 Among them, three rows of bolt holes 7 are arranged on the U-shaped support frame 3 and the reinforcing plate 6, and the three rows of screw holes 7 are arranged at equal vertical intervals. The high-strength bolts 4 pass through the bolt holes 7 on the U-shaped support frame 3 and the reinforcement plate 6 from the outside to the inside, and set the tightening nuts 5 on the parts outside the U-shaped support frame 3; the high-strength bolts 4 make the front end tighten The steel backing plate 2 is rotated outwardly at the same time the clamping nut 5, so that the clamping nut 5 is pressed against the U-shaped support frame 3 outwardly, and a certain prestress is applied to the steel backing plate 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com