Combined segment type drainage pipe culvert and pipe culvert construction method

A technology of combining pipes and segments, which is applied in sewer systems, waterway systems, water supply devices, etc., can solve the problems of difficult hoisting and construction of drainage pipes and culverts, and achieve the requirements of improving integrity and stability and reducing waterproof treatment. The effect of reducing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

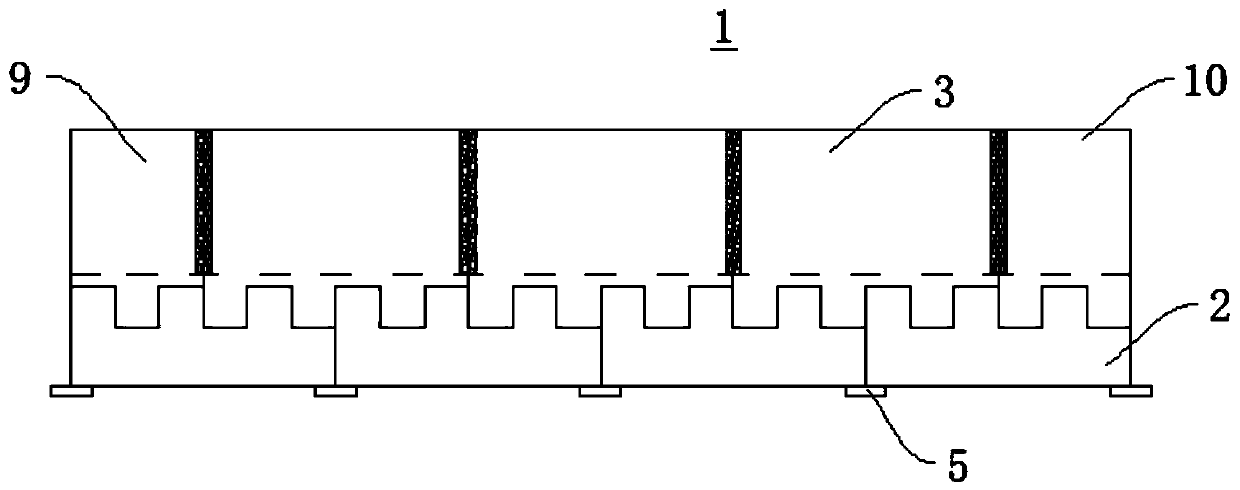

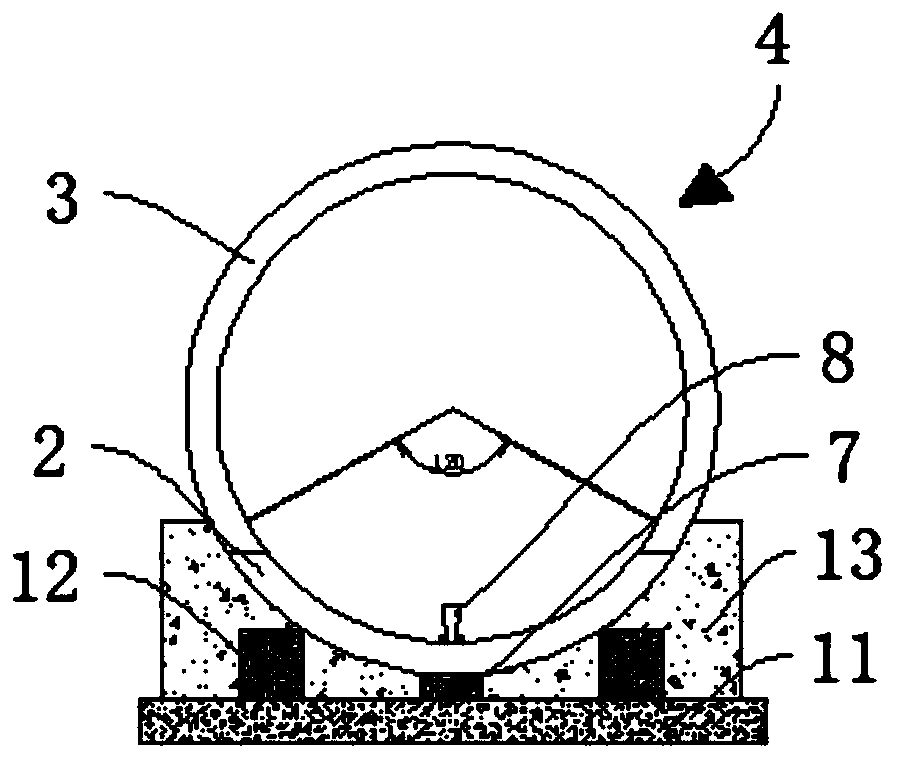

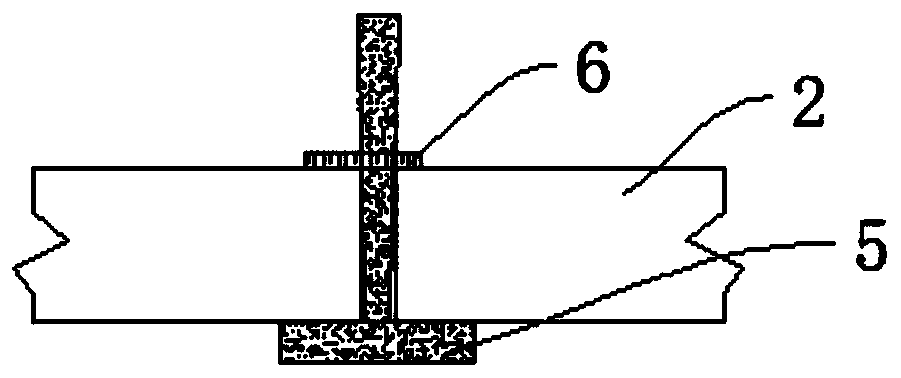

[0040] Please refer to figure 1 , with reference to Figure 2 to Figure 4, the present application provides a combined segment type drainage pipe culvert 1, comprising a left upper end segment 9, a right upper end segment 10, a plurality of first standard segments 2, a plurality of second standard segments 3 and a plurality of Connecting assembly 4, connecting assembly 4 comprises support 5 and bayonet 6, and support 5 comprises concrete pad 7 and vertical bar 8; Wherein, pouring concrete pad 11 in a foundation pit, then in the axial position of concrete pad 11 A plurality of concrete pads 7 arranged in parallel intervals are poured on the top, and each concrete pad 7 is vertically fixed with a vertical pole 8, and the width of the vertical pole 8 gradually increases from bottom to top; at the same time, each concrete pad 7 Concrete pillow blocks 12 are respectively poured on both sides of the two sides at a certain distance, and a plurality of first standard segments 2 are f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com