Control method of achieving automatic constant pressure of water pump by sensing current load

A technology of current load and control method, which is applied in the direction of pump control, pumps, pump devices, etc., and can solve problems such as easy corrosion and reduced service life of pump devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

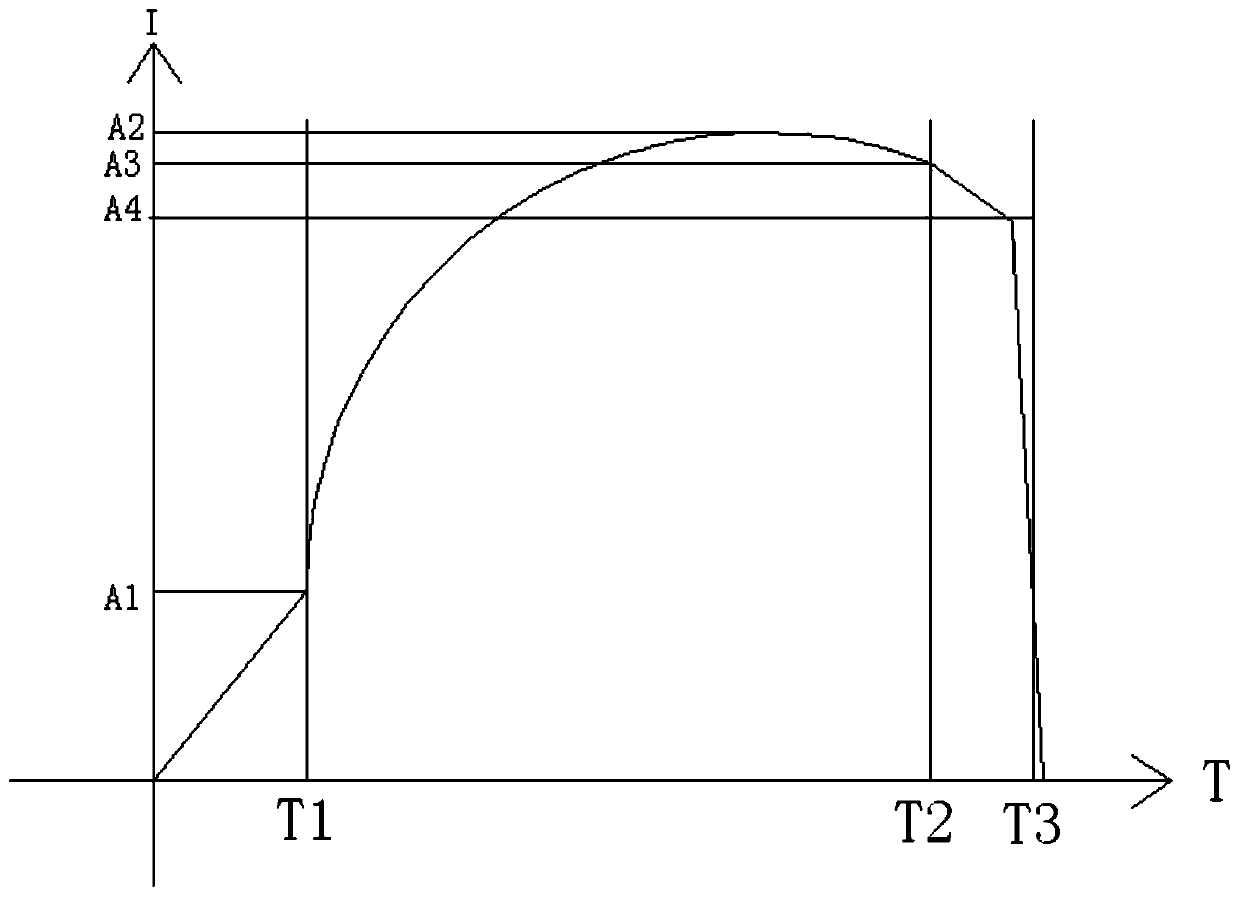

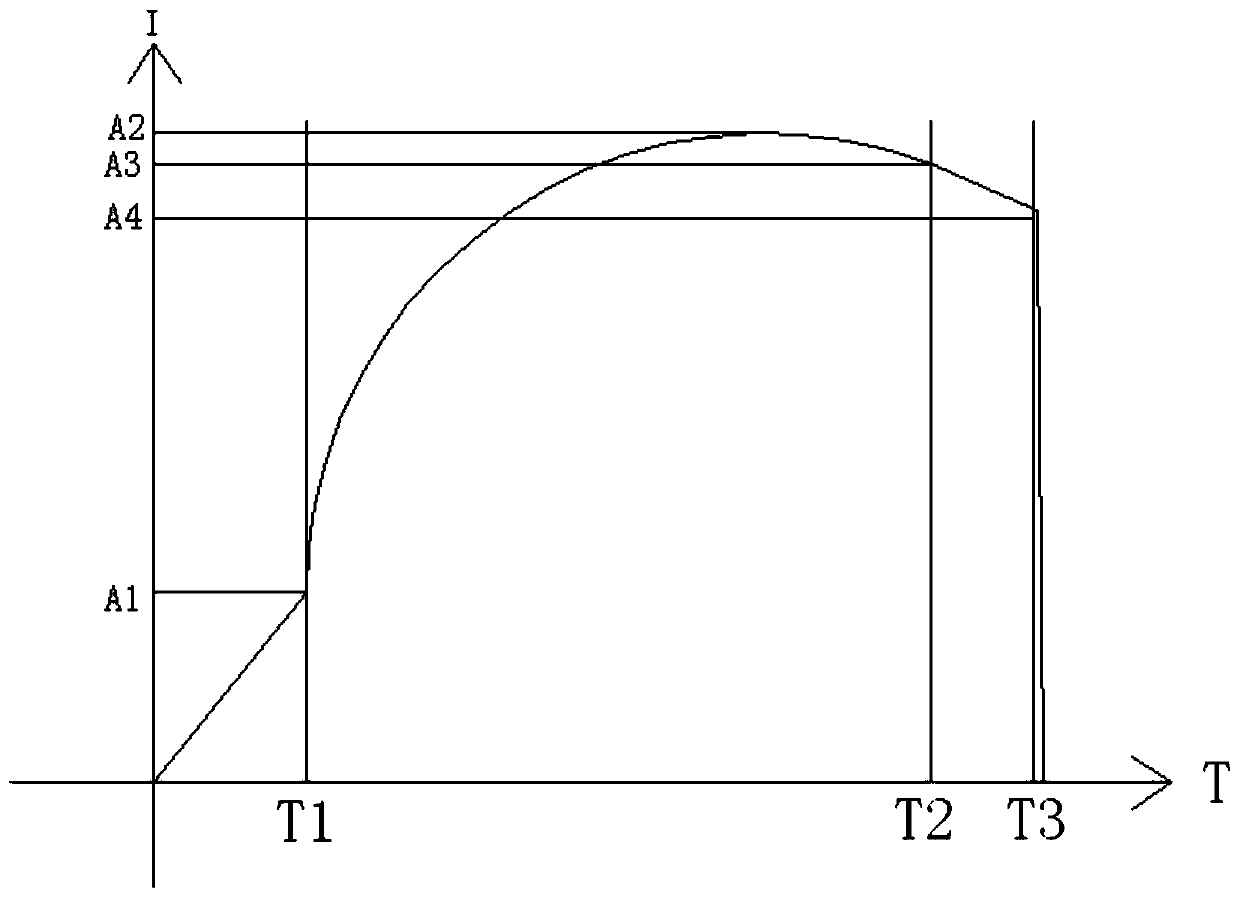

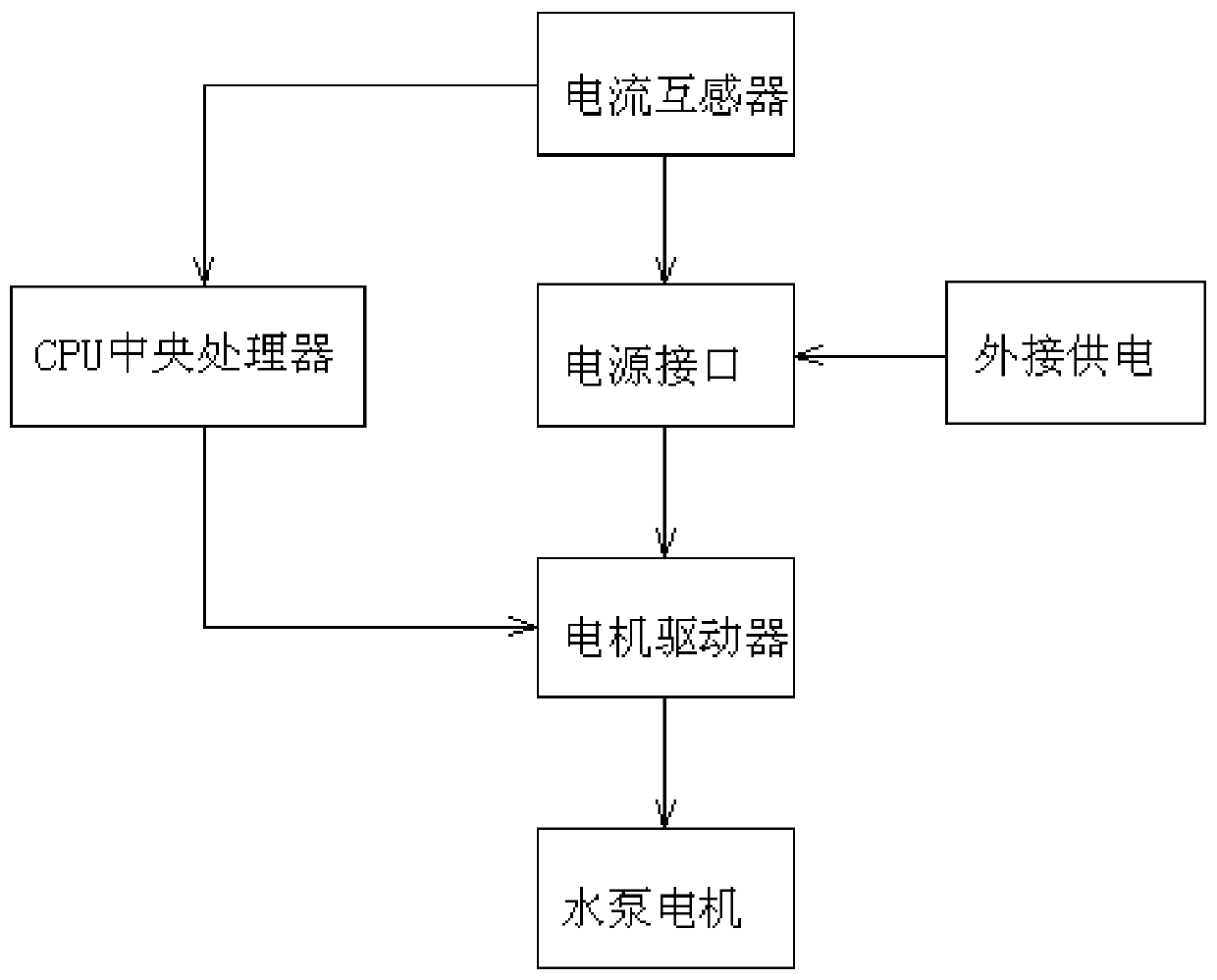

[0019] In this example, if Figure 1 to Figure 3 As shown, a control method for detecting the current load to realize the automatic constant pressure of the water pump according to the present invention, the control device for detecting the current load to realize the automatic constant pressure of the water pump includes a current transformer, a CPU central processing unit, a motor driver, a power interface and The water pump motor, the CPU central processing unit is electrically connected to the current transformer and the motor driver respectively, the motor driver is connected to the water pump motor, the motor driver is connected to the power interface, and the power interface is externally connected to an external power supply or commercial power, so The above-mentioned current transformers are respectively connected with the CPU central processing unit and the power supply interface, the power supply interface is connected with the CPU central processing unit through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com