A Method for Early Weak Fault Diagnosis of Aeroengine Intermediate Bearing

An aero-engine and fault diagnosis technology, which is applied in the testing of mechanical components, testing of machine/structural components, instruments, etc., can solve problems such as failure to reflect effective fault characteristic signals of bearing faults, and achieve the effect of avoiding major vicious accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

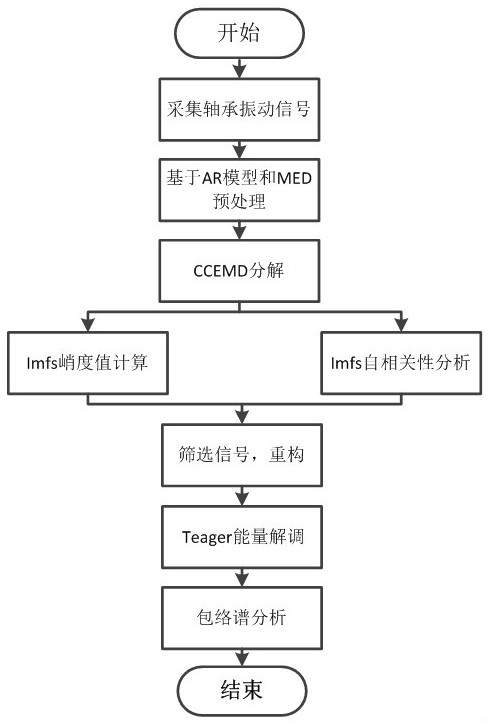

[0080] Such as figure 1 As shown, an early weak fault diagnosis method for an aero-engine intermediary bearing includes the following steps:

[0081] S1: Collect the fault signal of the intermediate bearing through the vibration sensor located on the casing of the outer duct;

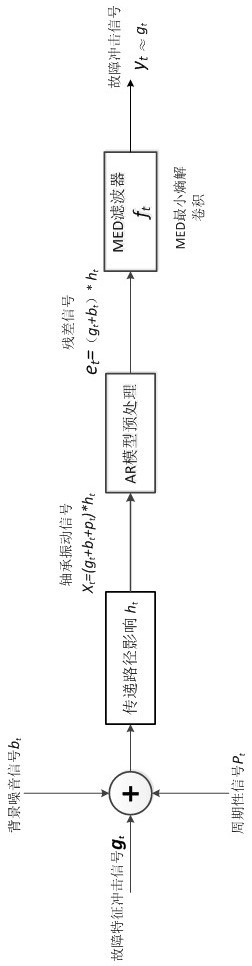

[0082] S2: Use the AR model to remove the deterministic signal generated by the periodic rotation of the engine rotor by using the fault signal collected in S1;

[0083] S3: Perform minimum entropy convolution MED inverse filtering on the fault signal processed by S2 to enhance the impact component in the fault signal, and realize the enhancement of the impact characteristics of the bearing fault;

[0084] S4: Use the CEEMD method to decompose the fault signal processed in S3, and filter the effective modal components according to the kurtosis value index and autocorrelation function to reconstruct the intermediate bearing fault signal with noise reduction;

[0085] S5: Obtain the output energy of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com