Bearing fault feature extraction method based on multi-period differential mean value and cyclic spectrum coherence

A technology of fault characteristics and extraction methods, applied in mechanical bearing testing, character and pattern recognition, instruments, etc., can solve problems such as frequency ambiguity, achieve the effect of enhancing the impact characteristics of bearing faults and enhancing the second-order cyclostationary characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

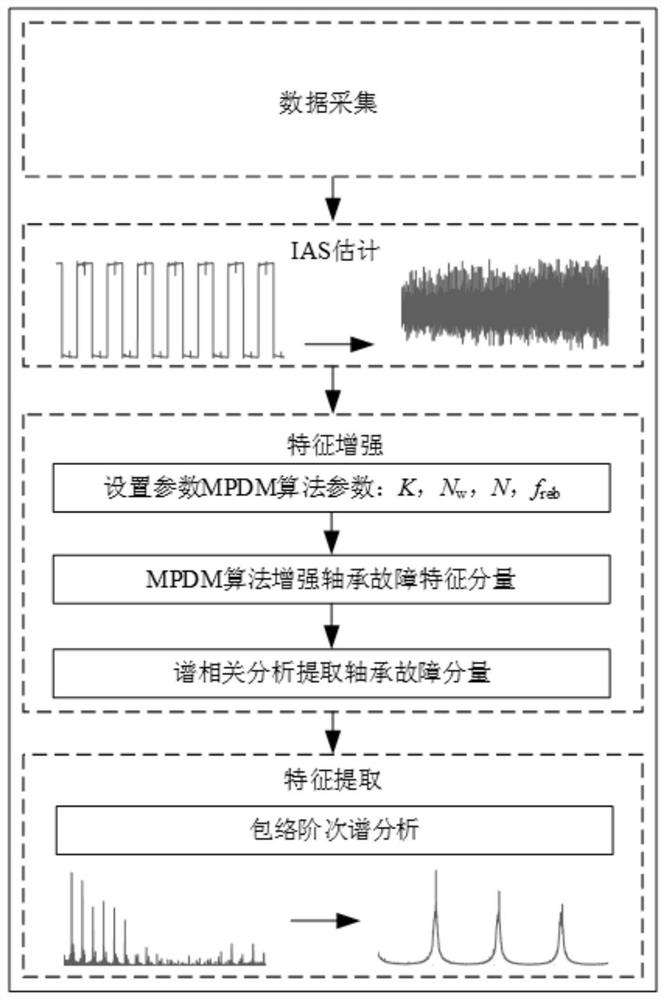

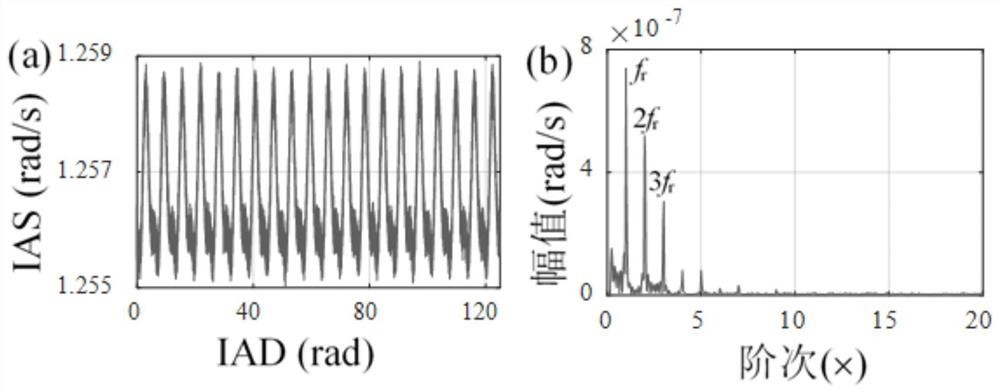

[0036] Example 1: as figure 1 As shown, this embodiment is the method of the present invention for extracting the fault characteristics of the simulated bearing, and the specific process includes:

[0037] The calculation formula of the bearing outer ring fault signal model used in the simulation analysis is:

[0038]

[0039]

[0040] where w(θ) represents the average angular velocity, w o (θ) represents the encoder installation error, ξ represents the damping coefficient, f n Represents fixed frequency, ψ=θ-jΘ-τ j , the angle sequence θ=2π / N, 4π / N, 6π / N..., n(θ) represents the encoder measurement noise, ρ=Δr / r is the ratio of the eccentric distance between the geometric center and the rotation center, r is the encoding The diameter of the encoder hole, Δr is the eccentric distance between the geometric center and the rotation center, β represents the inclination angle between the encoder rotary shaft and the rotary shaft, and the initial angle θ e ∈[φ e ,2kπ+φ e ...

Embodiment 2

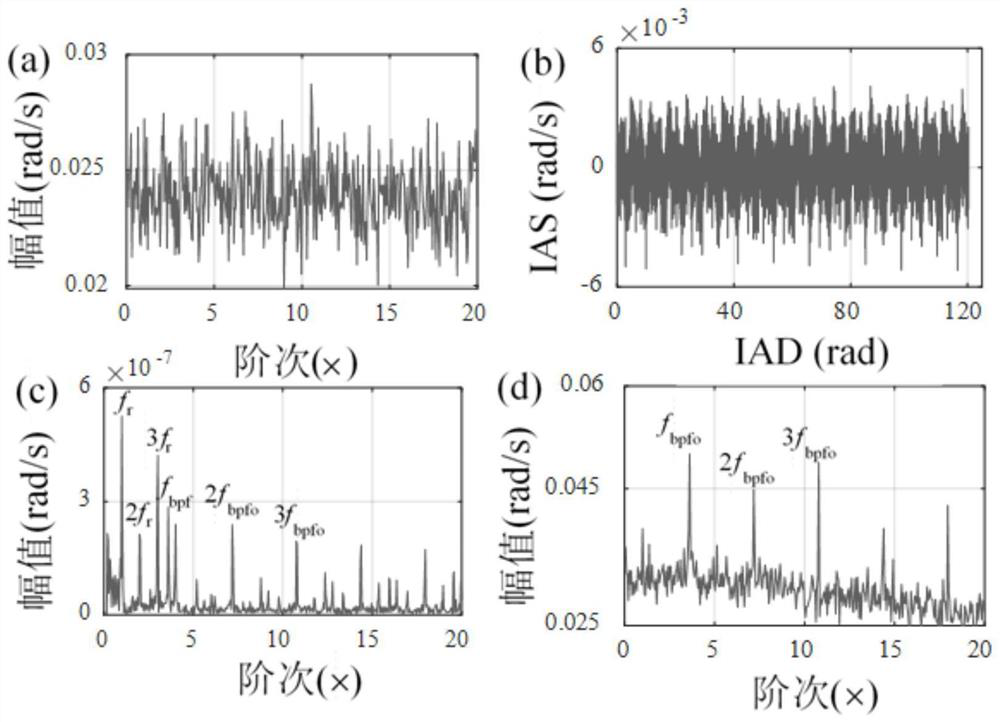

[0053] Embodiment 2: This embodiment describes that the method of the present invention is used to extract the fault characteristics of the actual rolling bearing outer ring

[0054] In this embodiment, a bearing test bench is used, such as Figure 5 As shown, an ETF100-H851007B optical encoder is installed on the experimental bench, the number of encoder lines is N=5000, and 10 6 The sampling rate PicoScope high-speed acquisition device obtains the corresponding angle information and time information. The bearing type of this test bench is NU206E (N b =13,E b =9.525,E p =46,α=0), in order to simulate the fault of the bearing outer ring, a groove with a width of about 0.3mm and a depth of about 0.28mm is machined on the outer ring by wire cutting; the fault characteristic frequency f of the bearing outer ring is obtained from the following formula reb is 5.15×.

[0055]

[0056] Step 1: Obtained IAS i The fault waveform of bearing outer ring is as follows Image 6 As...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com