Method for extracting Ti-rich compounds from Ti- containing slag

A compound and titanium slag technology, which is applied in the field of separation and extraction of titanium-rich compounds, can solve the problems of short process flow, complex process, secondary pollution, etc., and achieve the effect of short process flow, simple equipment and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Titanium-containing blast furnace slag (main components are: MgO content is 6.93wt%, Al 2 o 3 content of 13.04wt%, CaO content of 26.86wt%, SiO 2 Content is 24.26wt%, TiO 2 The content is 22.58wt%) and the acidic oxide SiO 2 (addition is 28wt% of slag amount) and P 2 o 5 (Addition amount is 4wt% of slag amount) put into graphite crucible (reductive agent), be heated up to 1500 ℃ of melting in silicon-molybdenum furnace after heat preservation 2 hours, drop rapidly to 1220 ℃ of heat preservation 3 hours, rapidly cool to room temperature, 77% Titanium dioxide can be enriched in black titanite without other crystals, which is beneficial for subsequent separation. However, in the comparative example, titanium is dispersed in various titanium-containing crystals, which makes it difficult to enrich titanium and is not conducive to the subsequent separation of titanium.

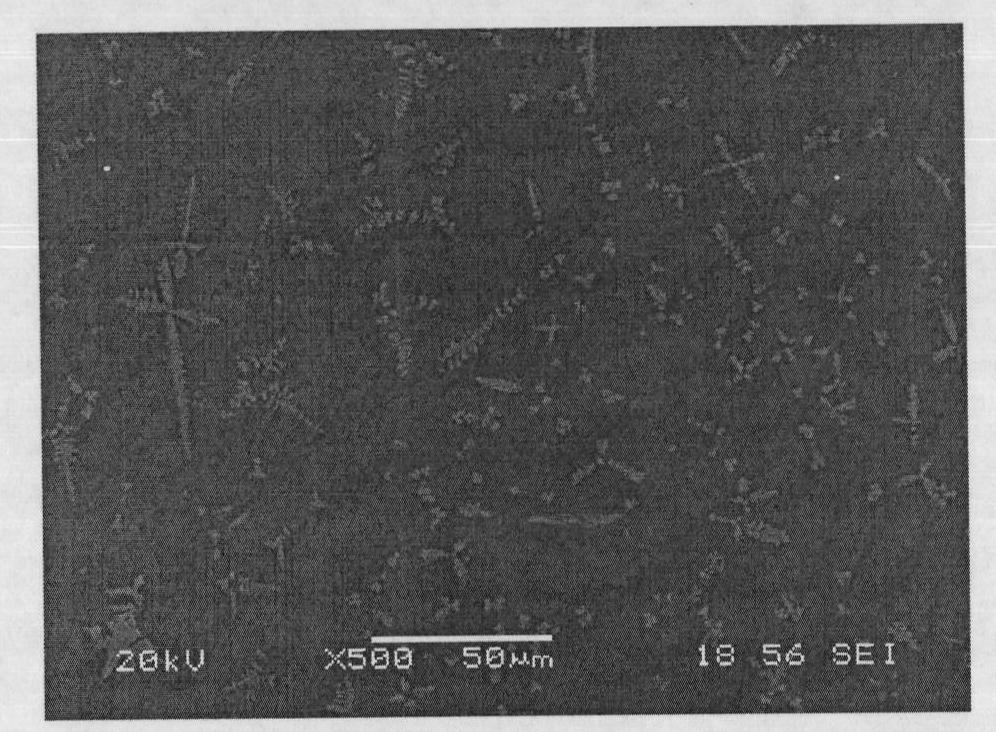

[0039] image 3 , Pic 4-1 , 4-2 It is a scanning electron microscope photo and an energy spectru...

Embodiment 2

[0044] Titanium-containing blast furnace slag (main components are: MgO content is 6.93wt%, Al 2 o 3 content of 13.04wt%, CaO content of 26.86wt%, SiO 2 Content is 24.26wt%, TiO 2 The content is 22.58wt%) and the acidic oxide SiO 2 (Addition amount is 52wt% of slag) into graphite crucible (reductive agent), be heated up to 1430 ℃ of melting in silicon-molybdenum furnace after heat preservation 1 hour, drop rapidly to 1260 ℃ of heat preservation 5 hours, quench and cool to room temperature then. Through XRD analysis and metallographic microscope observation, the chemical formula of black titanite is Mg 0.3 Ti 2.7 o 5 , the diameter of black titanium stone is 20-30um, no other crystals are formed, which is beneficial to the subsequent separation of black titanium stone.

[0045] Figure 5 , Figure 6 The XRD spectrum and metallographic micrographs of the black titanite crystal obtained in this embodiment.

Embodiment 3

[0047] Titanium-containing blast furnace slag (main components are: MgO content is 6.93wt%, Al 2 o 3 content of 13.04wt%, CaO content of 26.86wt%, SiO 2 Content is 24.26wt%, TiO 2 The content is 22.58wt%) and the acidic oxide SiO 2 (addition amount is 26wt% of slag) puts into molybdenum crucible, outer jacket graphite crucible, heats up to 1465 ℃ of melting insulations in silicon-molybdenum furnace after 4 hours, drops rapidly to 1200 ℃ of insulations for 12 hours, then quenches and cools to room temperature, the whole experiment CO gas (reducing agent) is passed through the process, and the flow rate is 80ml / min. Through XRD analysis and metallographic microscope observation, the chemical formula of black titanite is Ti 3 o 5 , no other crystals are formed, which is beneficial to the subsequent separation of black titanite.

[0048] Figure 7 , Figure 8 The XRD spectrum and energy spectrum analysis line scan photos of the black titanite crystal obtained in this examp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com