Preparation process of lithium bis (oxalato) borate

A technology of lithium bis-oxalate borate and preparation process, which is applied in the field of preparation technology of lithium bis-oxalate borate, can solve the problems of 316L stainless steel being difficult to use in the synthesis process of lithium bis-oxalate borate, increasing repair difficulty, time cost, and increasing metal ions, etc. Avoid corrosion and excessive metal ion problems, avoid maintenance costs and time costs, and reduce the effect of metal ion introduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] The invention provides a kind of preparation technology of lithium bisoxalate borate, comprising the steps of:

[0049] 1) Carry out the aqueous phase synthesis reaction by two-stage method:

[0050]Add deionized water into the enamel reaction kettle, stir, heat up to 80°C, gradually add 39kg of oxalic acid dihydrate and 9.5kg of boric acid, heat up to 80°C, gradually add 5.9kg of lithium carbonate for lithiation hydrolysis reaction, heat up to Dehydrate at 150°C for 1 hour, then heat up to 180°C for 3 hours, until the liquid appears slurry (one stage synthesis); then open the valve between the enamel kettle and the stainless steel synthesis kettle, and transfer the material to the stainless steel synthesis kettle under a pressure of 0.2MPa , heat up to 240°C for another 4 hours, and take samples for testing. After the moisture and acidity meet the requirements, stop heating and lower the temperature to below 40°C (two-stage synthesis);

[0051] 2) Dissolution: Add 250...

Embodiment 2

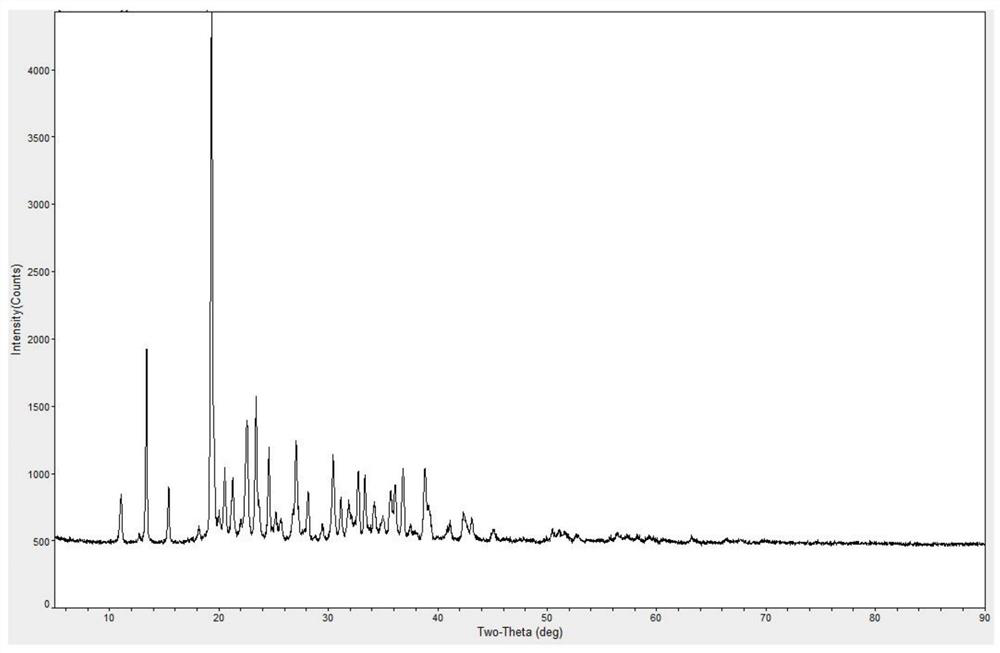

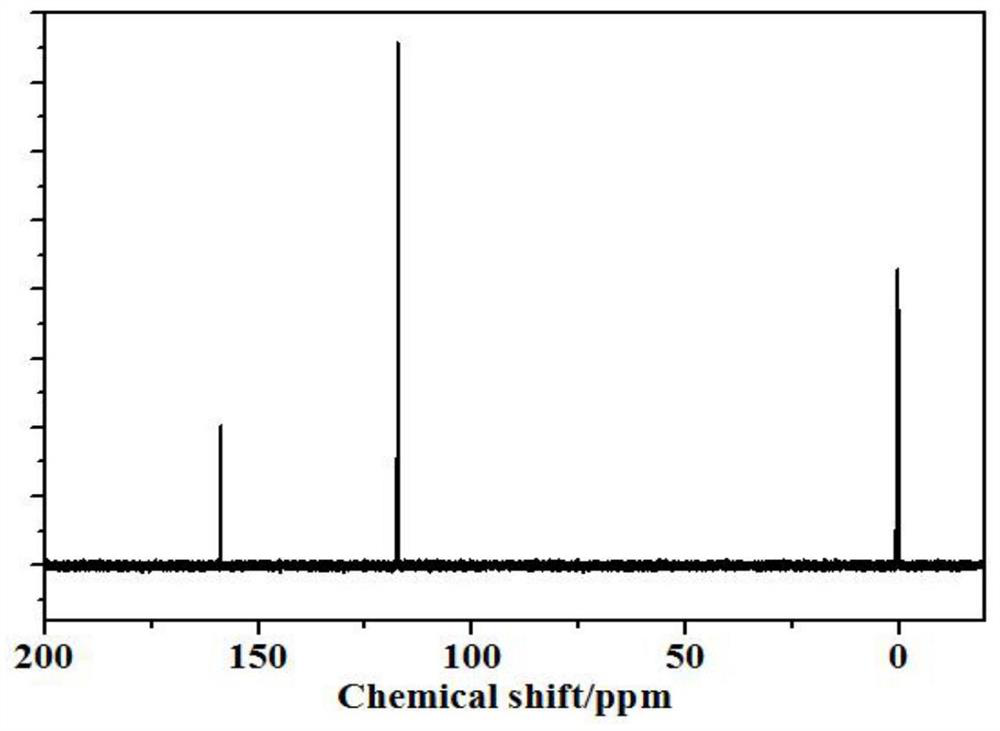

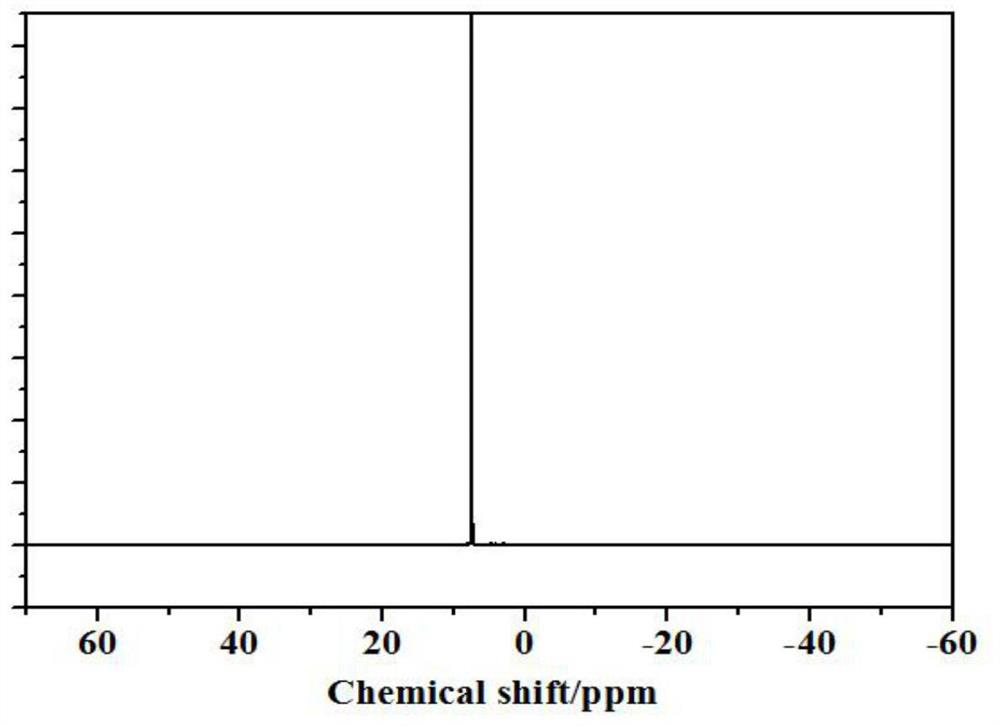

[0056] Example 2, see Figure 1 to Figure 3 :

[0057] The present invention provides a preparation process of lithium bisoxalate borate, the steps are basically the same as in Example 1, the difference is that acetonitrile is used for purification, that is, when the temperature drops below 40°C, acetonitrile solvent is added to the crude product of lithium bisoxalate borate 250kg, stirred for 1h; under the pressure of 0.2MPa, the suspension was filtered through a microporous filter into the evaporation kettle, and the acetonitrile solvent was concentrated at -0.08MPa and 70°C, and 180kg of acetonitrile solvent was evaporated, and then The concentrated mother liquor was transferred to the crystallization kettle, and the cold water valve was opened to lower the temperature; when the temperature dropped to -5°C, 280kg of precipitant dichloromethane was added to the solution.

[0058] Using X-ray diffraction spectrum (XRD) and carbon nuclear magnetic resonance spectrum respectiv...

Embodiment 3

[0060] The present invention provides a preparation process of lithium bisoxalate borate, the steps of which are basically the same as those in Example 2, the difference being that the first stage of synthesis is maintained at 180°C for 2 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com