Multi-lifting platform control system and method

A lifting platform and control system technology, applied in the field of lifting platforms, can solve the problems of wasting power resources, standby power consumption, low lifting frequency of lifting platforms, etc., and achieve the effects of saving power resources, avoiding insufficient voltage, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

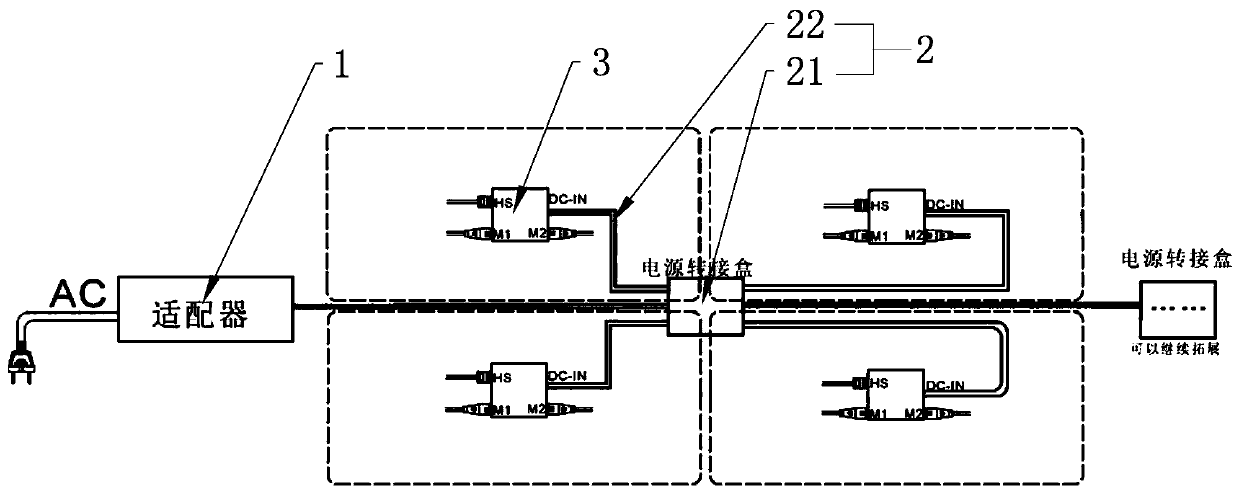

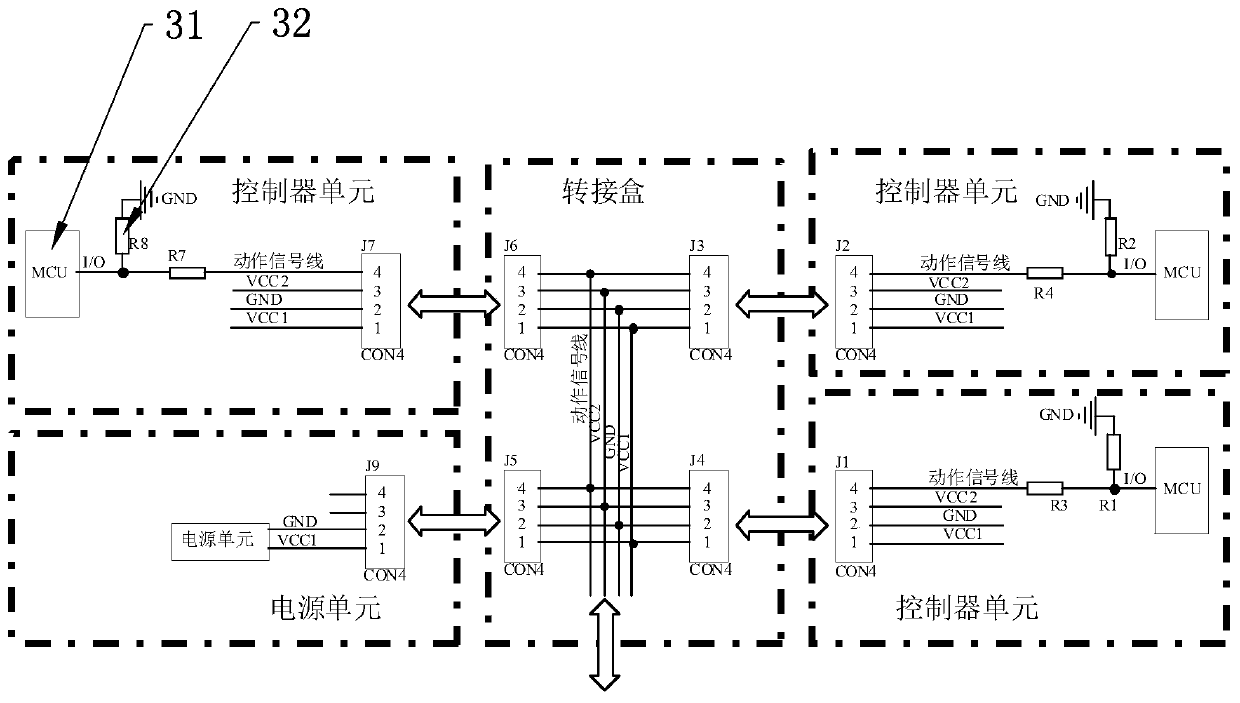

[0031] A control system for multiple lifting platforms, including a power supply module 1, an adapter module 2 and a plurality of control modules 3 that control the lifting of corresponding lifting platforms, the adapter module 2 is used to connect multiple control modules 3; the power supply module 1 and multiple control modules The modules 3 are connected to supply power to multiple control modules 3 at the same time; the control module 3 detects the operating status of other control modules 3 through the adapter module 2, and the control module 3 is set to detect that other control modules 3 are in the working state. The control module 3 is in a non-working state. The present invention realizes the connection between multiple control modules 3 through the adapter module 2, so that a single power supply module 1 can supply power to multiple control modules 3 at the same time, without requiring each control module 3 to be provided with a corresponding power supply module 1, re...

Embodiment 2

[0036] The difference between this embodiment and Embodiment 1 is that the control module 3 is a controller, and the power module 1 is a power supply unit installed in a certain controller. , the power supply unit can supply power to other controllers that are not provided with a power supply unit through the adapter box 21, and there is no need to provide a power adapter.

Embodiment 3

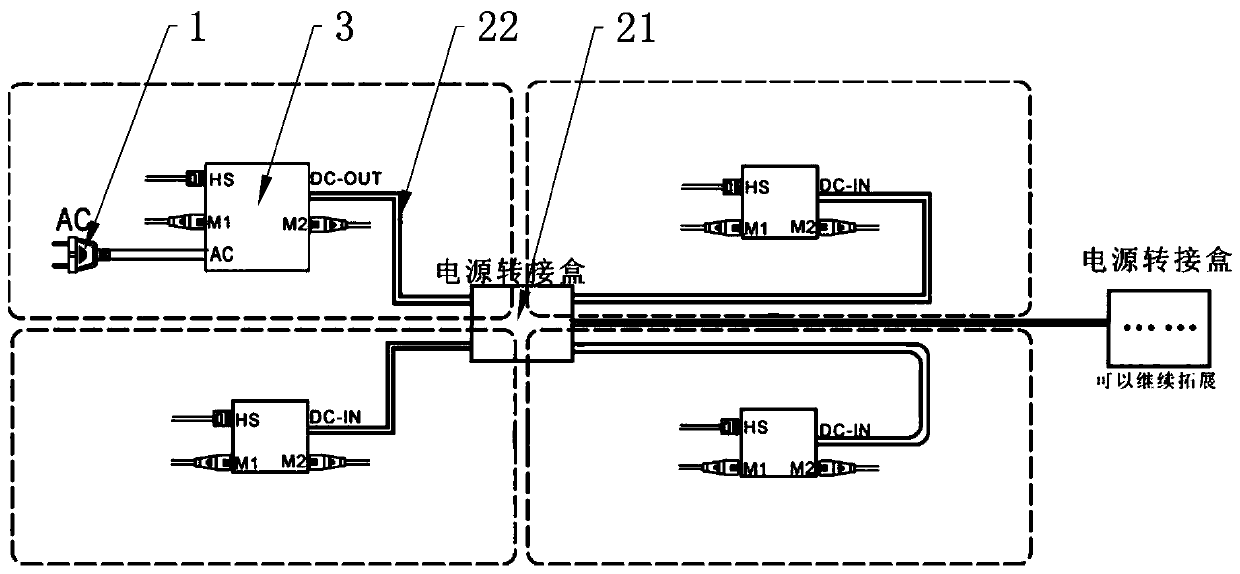

[0038] The difference between this embodiment and Embodiment 1 is that the adapter module 2 includes a plurality of adapter wires 22, the power module 1 is connected to one of the control modules 3, and the other control modules 3 are serially connected to the control module through the adapter wires 22 in turn. 3, the power supply module 1 realizes power supply to multiple control modules 3 through the adapter wire 22.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com