A general-purpose drum bottom wall scrubbing device

A general-purpose, drum technology, applied in cleaning methods and utensils, cleaning hollow objects, chemical instruments and methods, etc., can solve problems such as low efficiency and labor consumption, and achieve convenient operation, improve brushing efficiency, and strong applicability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

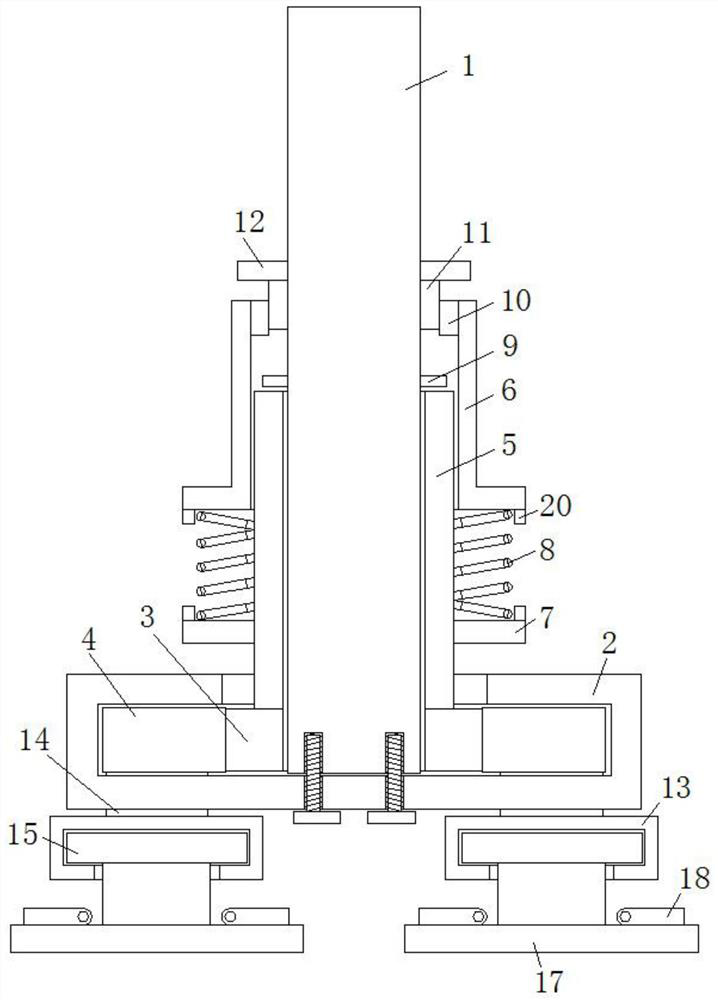

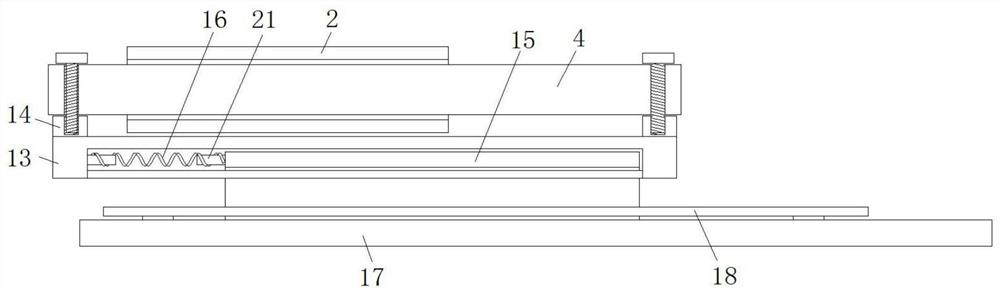

[0025] refer to Figure 1-4 , a general-purpose drum bottom wall scrubbing device, comprising a vertical control rod 1, the bottom of the vertical control rod 1 is provided with a bottom rectangular frame 2, the top side of the bottom rectangular frame 2 is provided with a top groove, and the two sides of the top groove The inner walls are respectively provided with side slide grooves, the bottom end of the vertical control rod 1 is fixedly connected with the inner wall of the top groove by bolts, and the outer rotation sleeve of the bottom end of the vertical control rod 1 is provided with a middle gear ring 3, and the two ends of the middle gear ring 3 The two tooth plates 4 are meshed and connected to the sides respectively, and the two tooth plates 4 are respectively slidably connected in the side chute, and the two ends of the tooth plates 4 respectively extend to the outside of the bottom rectangular frame 2, and the top end of the middle tooth ring 3 is fixedly connected...

Embodiment 2

[0029] Such as Figure 1-4 As shown, this embodiment is basically the same as Embodiment 1. Preferably, the two tooth plates 4 are arranged axisymmetrically with respect to the vertical central axis of the vertical control rod 1 .

[0030] In this embodiment, during adjustment, the rotation of the middle gear ring 3 can drive the gear plate 4 to move in the opposite direction, and the vertical control rod 1 is always located on the vertical central axis of the device.

Embodiment 3

[0032] Such as Figure 1-4 As shown, this embodiment is basically the same as Embodiment 1. Preferably, the sides of the control cylinder 6 and the limit bottom ring 7 are fixedly connected with the spring positioning ring 20 respectively, and the two ends of the return spring 8 are respectively arranged on the spring Inside the positioning ring 20 , a spring positioning post 21 is fixedly connected to the vertical side of the slide plate 15 and the inner wall of one side of the horizontal chute, and the two ends of the booster spring 16 are respectively sleeved on the outside of the spring positioning post 21 .

[0033] In this embodiment, the arrangement of the spring positioning ring 20 and the spring positioning column 21 makes the return spring 8 and the booster spring 16 more stable during retraction and retraction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com