Ultrathin lifting omnidirectional AGV (automatic guided vehicle)

A technology of ultra-thin and guide wheels, applied in the direction of lifting devices, etc., can solve the problems of old factory buildings without logistics channels, low automation level, and large turning space, and achieve the effect of small and compact structure, small occupation, and small sliding resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

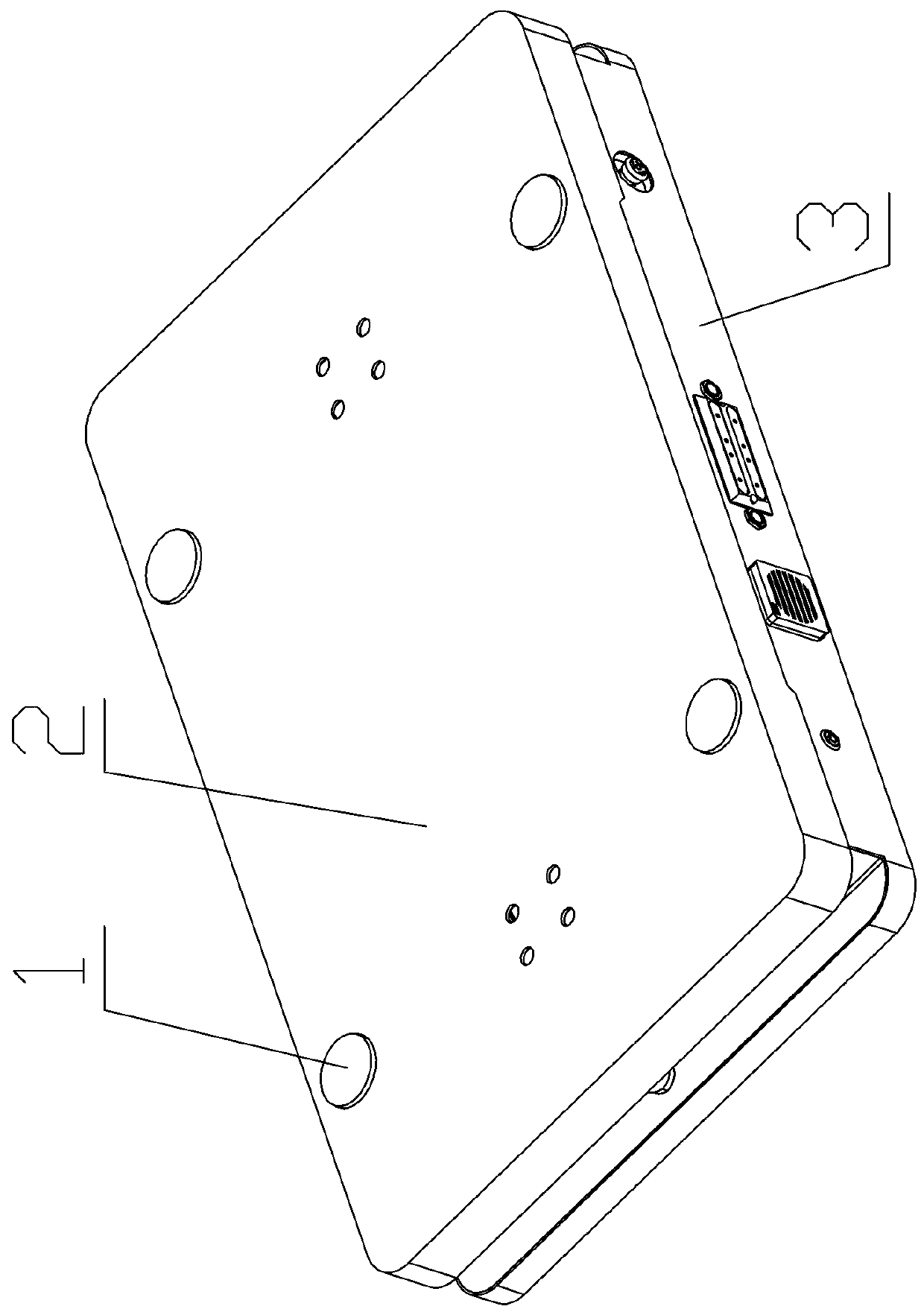

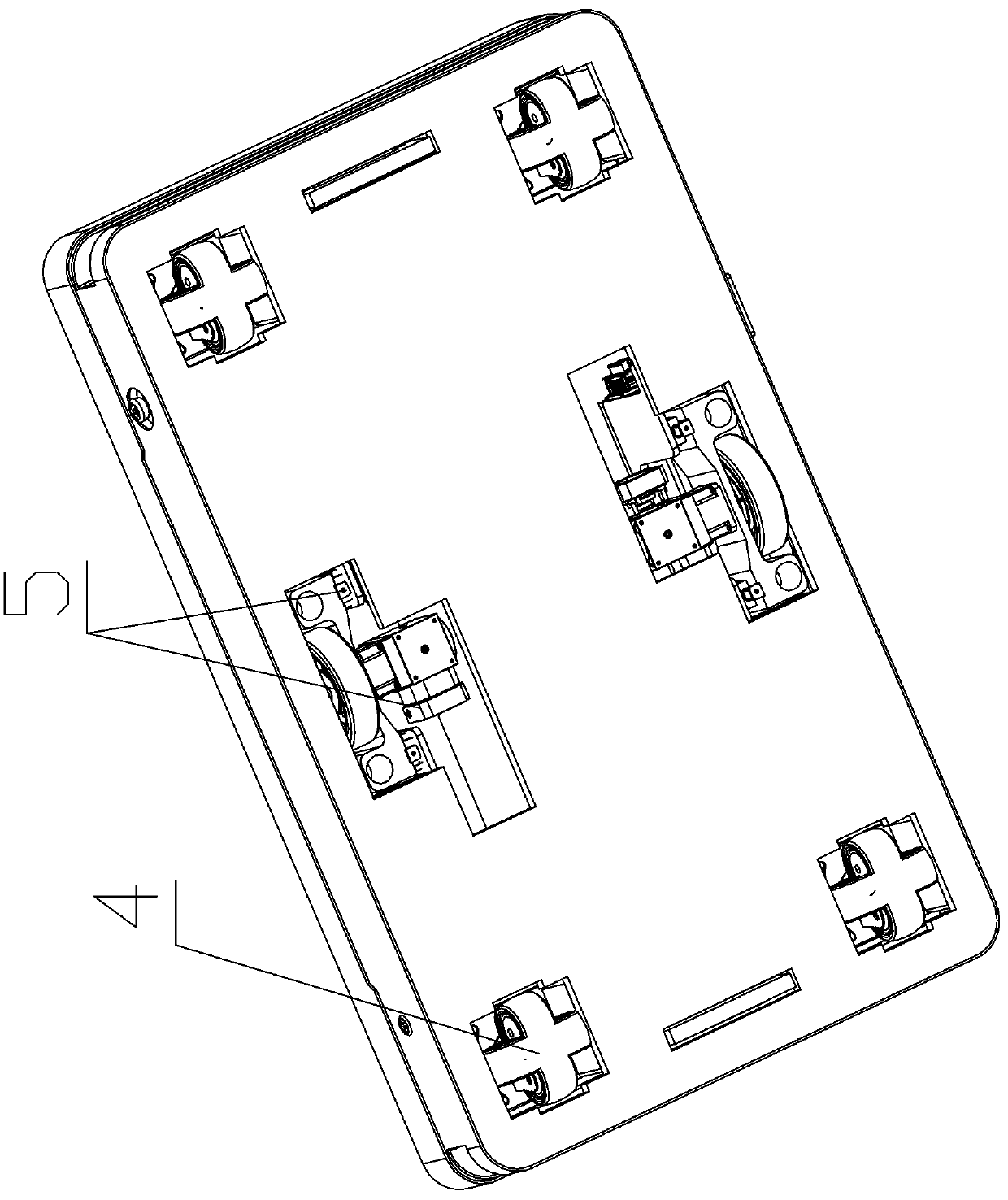

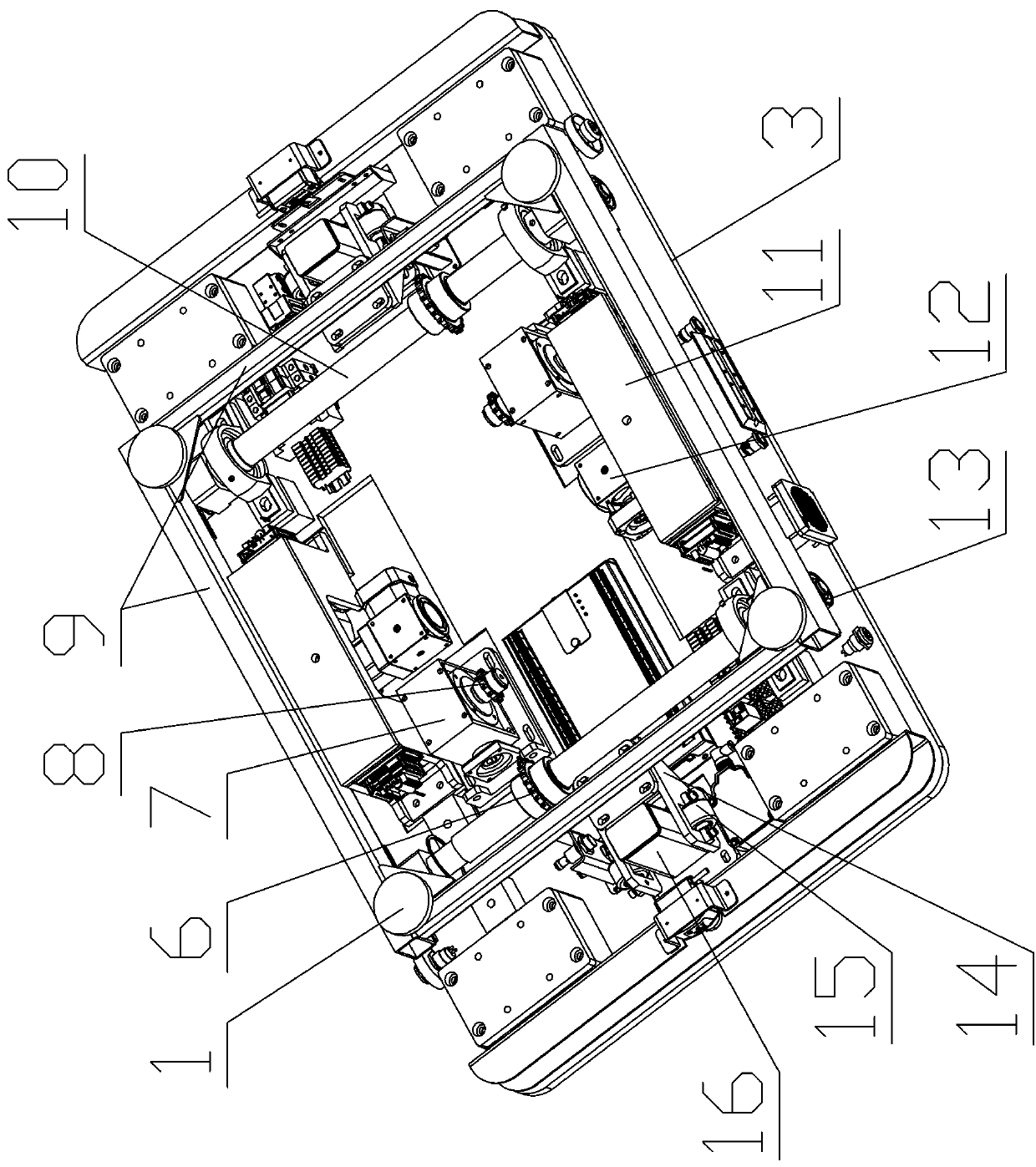

[0022] see Figure 1-Figure 5 , the present invention is an ultra-thin lifting omnidirectional AGV, which has a car body floor 3, universal wheels 4 are embedded in the four corners of the bottom of the car body floor, and two sets of wheels are embedded in the front and rear sides of the bottom middle of the car body floor Differential drive unit 5; Cam lifting mechanism is equipped with on the car body bottom plate, and described cam lifting mechanism includes two sets of lifting reduction motors 7, sprocket chain transmission mechanism, two camshafts 10, lifting cam 13, Lifting frame 9 and two sets of guide mechanisms, the two ends of each camshaft are equipped with lifting cams, and the lifting frame is jointly supported on the four lifting cams, and the lifting panel 2 is installed on the lifting frame. The wheel transmission mechanism includes a small sprocket 8 mounted on the output end of the lifting reduction motor and a large sprocket 6 mounted on the corresponding c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com