Fixing device of floating slab track supporting structure

A supporting structure and fixing device technology, applied in the direction of tracks, roads, ballast layers, etc., can solve the problems of affecting continuity, increasing the complexity of force transmission mechanism, and cumbersome assembly process, so as to improve installation efficiency and facilitate maintenance and replacement work Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

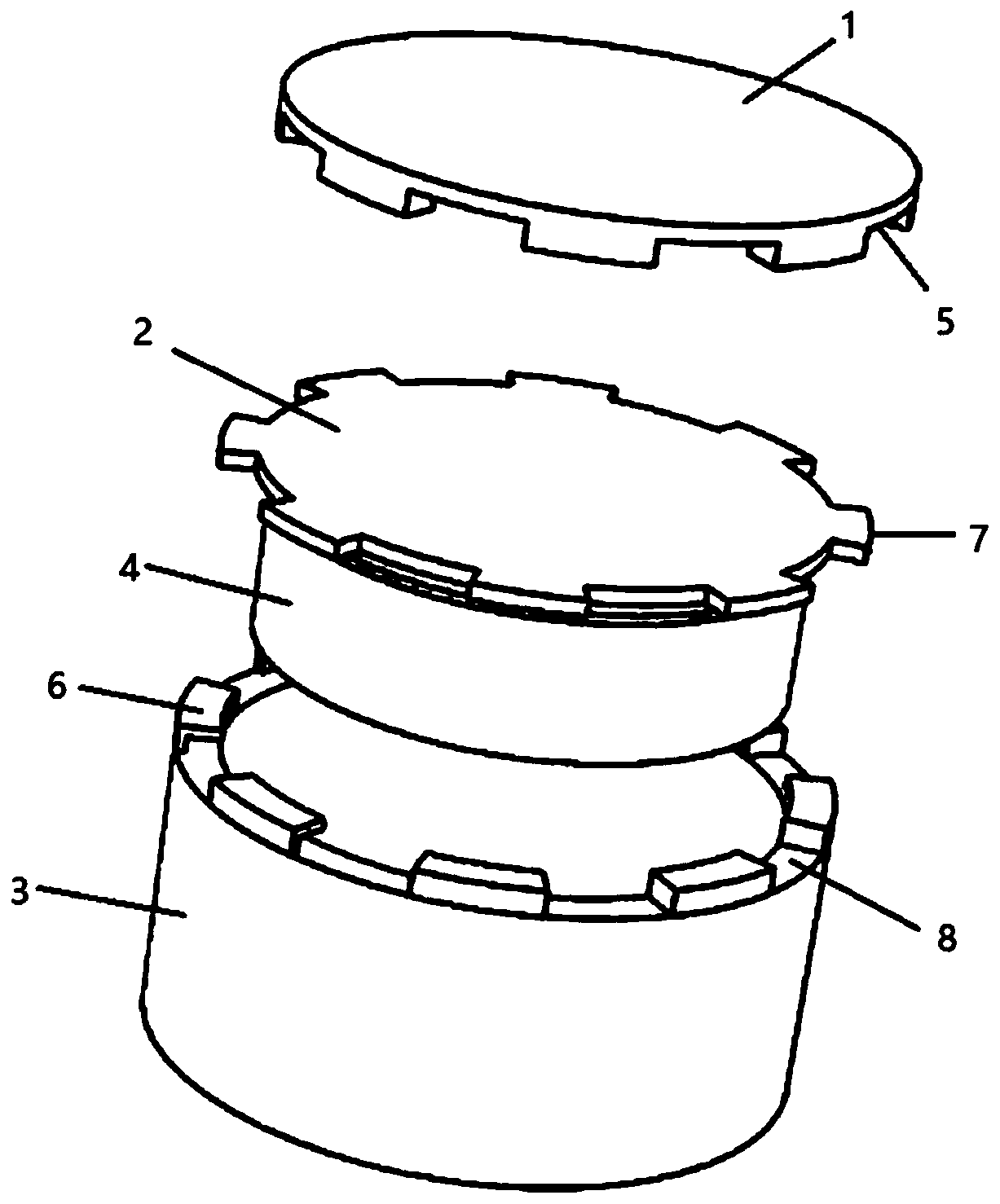

[0030] The fixing device for the support structure of the floating plate track in this embodiment includes a sleeve 3, a toothed disc 3 and a cover plate 1, see figure 1 .

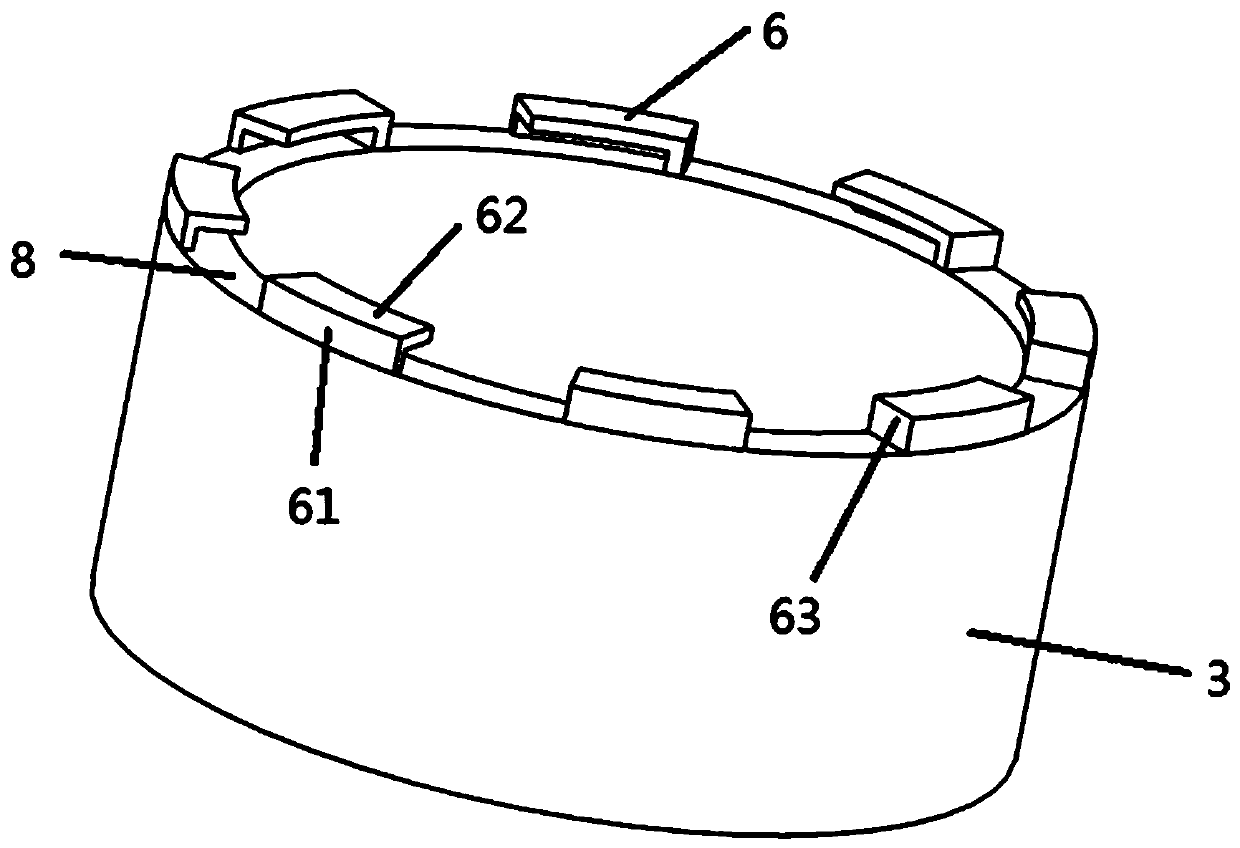

[0031] Sleeve 3: it is set on the support structure 4, see figure 1 , the bottom end of the sleeve 3 is pressed against the foundation, the middle part and the top end are arranged inside the floating plate track, and the top end is evenly distributed along the circumferential direction with a plurality of raised L-shaped clamping plates 6, the L-shaped clamping plates 6, and the top of the sleeve 3 An L-shaped groove with a horizontal opening is formed between the upper edges, and a positioning opening 8 is formed between adjacent L-shaped clamping plates 6 . The L-shaped clamping board includes a first vertical surface 61, a second vertical surface 62 and a third vertical surface 63, see figure 2 . The first elevation 61 is parallel to the axis of the sleeve 3, one side of the first elevation 61 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com