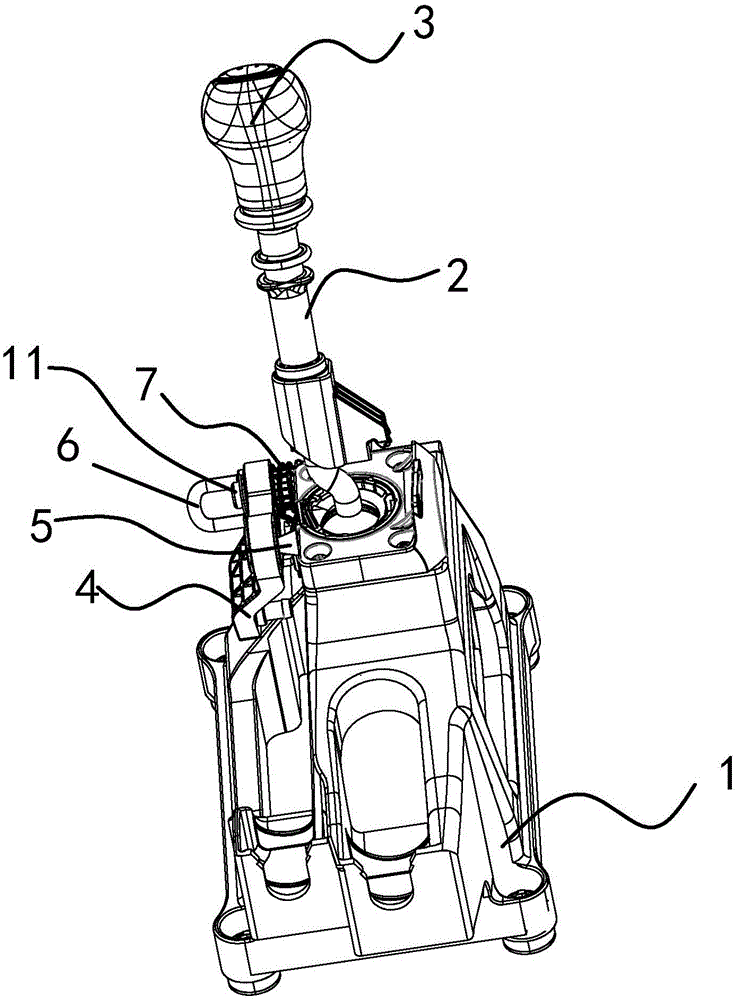

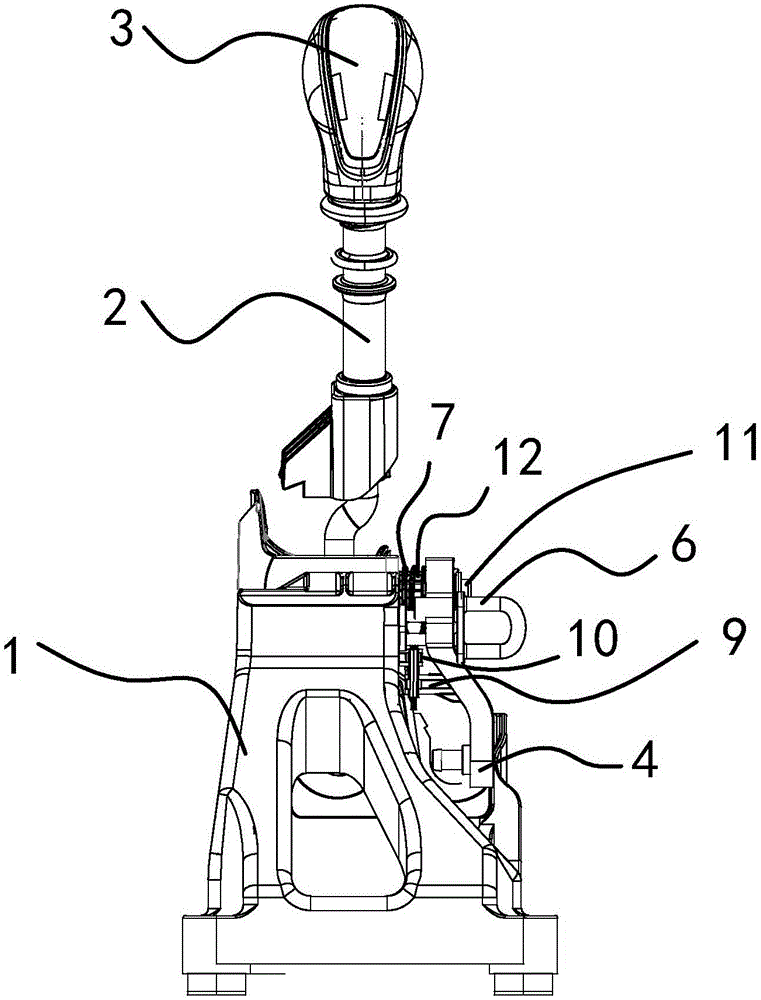

Gear shifting operation mechanism assembly

An operating mechanism and assembly technology, applied in the direction of mechanical equipment, toothed components, belts/chains/gears, etc., can solve problems such as poor transmission fluency, affecting driving experience, loose structure, etc., so that it is not easy to block Feeling and frustration, simple and reasonable structure, the effect of reducing the gap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

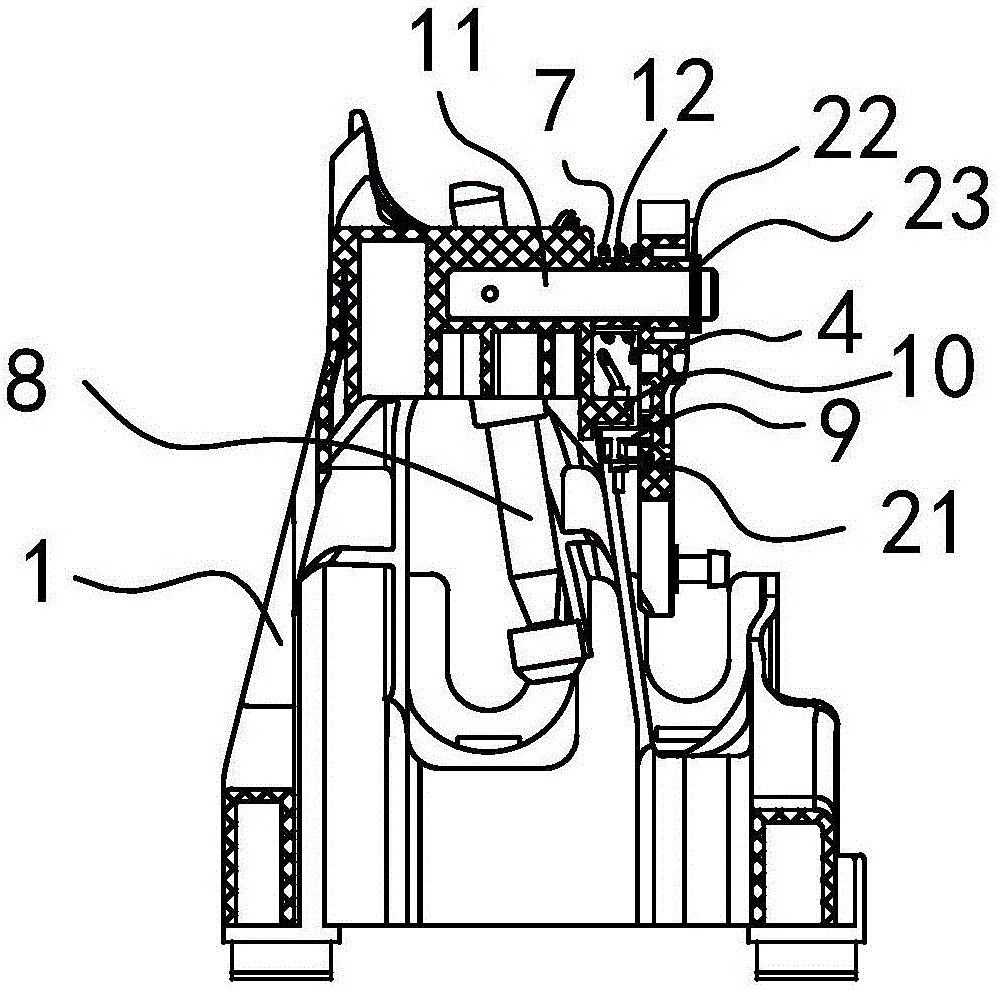

[0028] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0029] As shown in the figure, the present invention provides a shift operating mechanism assembly, including a base 1, a joystick assembly and a shift arm assembly. The base 1 is provided with an operation inner chamber, and the upper part of the base 1 is provided with a mounting frame, and a longitudinal installation opening is arranged on the mounting frame, and the installation port communicates with the operation inner chamber. The joystick 2 assembly includes a joystick 2 and a rotating center ball 14. The rotating center ball 14 is installed in the installation port of the mounting frame. The rotating center ball 14 can rotate in the installation port. The lower end of the joystick 2 is fixed on the rotating center ball 14, the joystick 2 stretches out of the mounting opening, and the upper end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com