Culture device with water quality purification function

A water purification and functional technology, applied in the field of aquaculture, can solve the problems that the aquaculture equipment does not have water purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

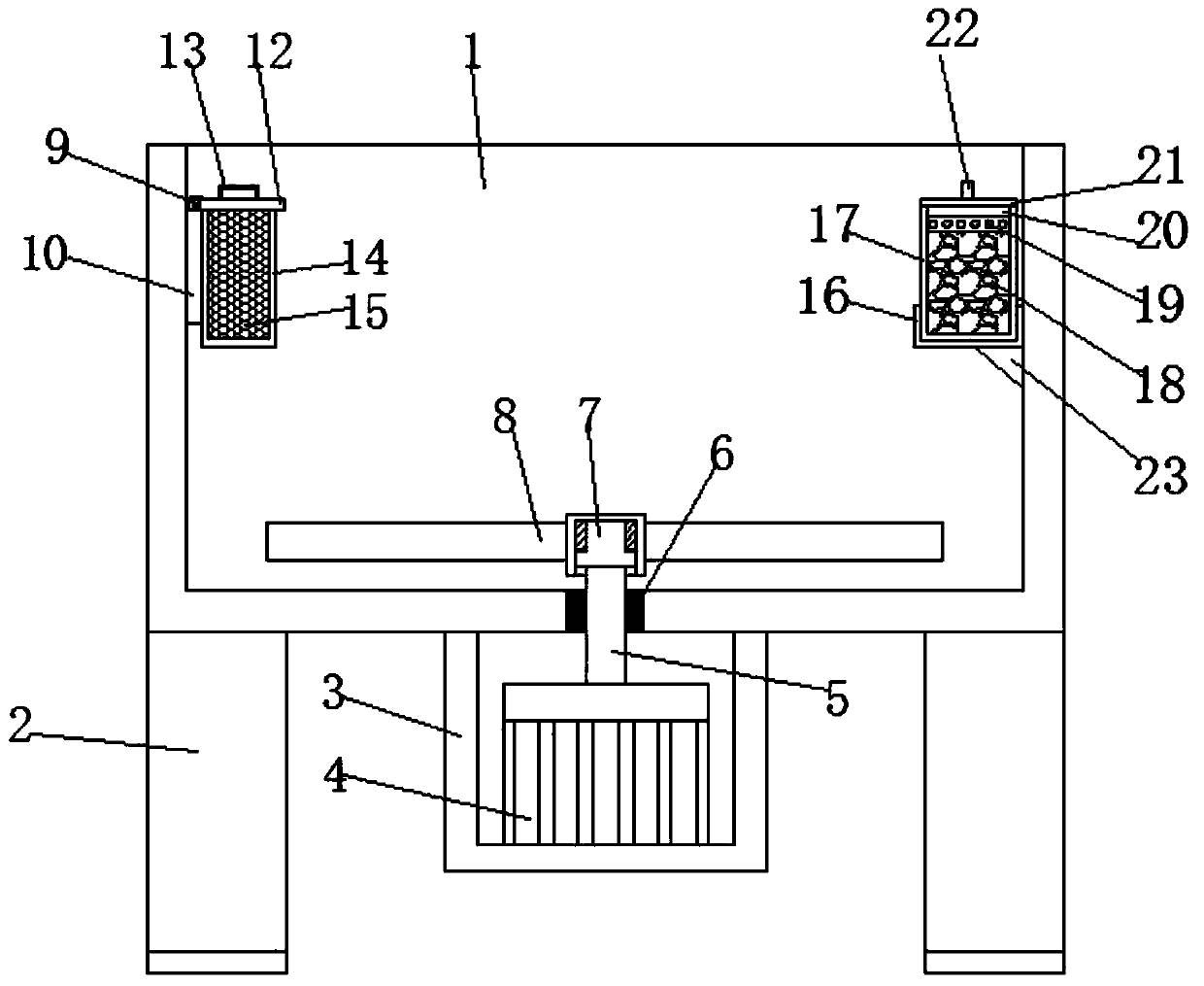

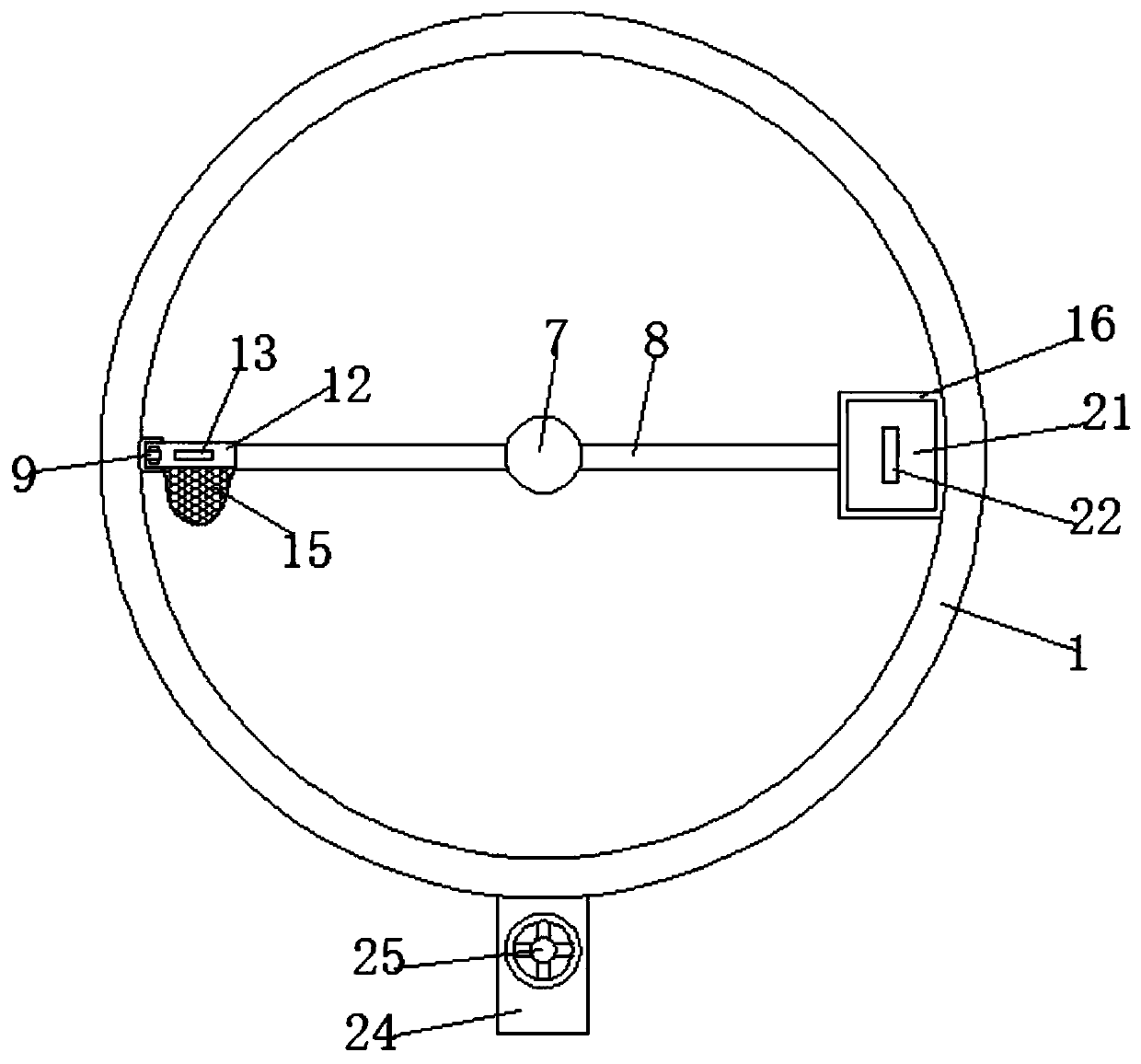

[0022] refer to Figure 1-2 , a breeding device with water purification function, comprising a main casing 1, feet 2 are fixed on both sides of the bottom of the main casing 1, and anti-slip mats are fixed on the bottom of the feet 2, the anti-slip mats can prevent the feet 2 from sliding, and the main casing 1 is connected to a water outlet pipe 24 on the lower side, and a valve 25 is installed on the water outlet pipe 24. The water in the main housing 1 can be discharged through the water outlet pipe 24. A bracket 3 is fixed in the middle of the bottom of the main housing 1, and the bracket 3 is installed There is a motor 4, one side of the motor 4 is connected with a rotating shaft 5, one end of the rotating shaft 5 passes through the bottom of the main casing 1 and extends upward, one end of the rotating shaft 5 is connected with a stirring mechanism, and the contact between the rotating shaft 5 and the bottom of the main casing 1 is fixed with a sealed bearing 6 , the sea...

Embodiment 2

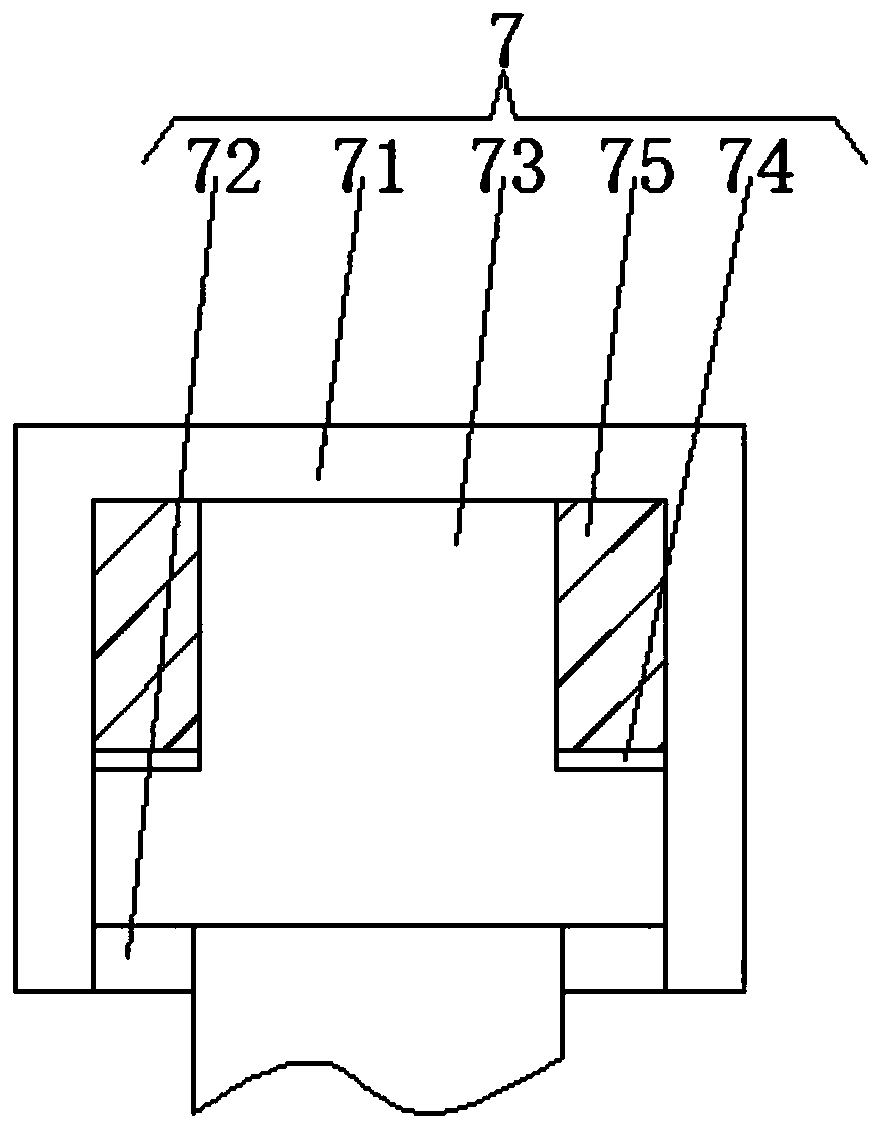

[0025] refer to Figure 1-3 , as another preferred embodiment of the present invention, the difference from Embodiment 1 is that the stirring mechanism includes an insertion mechanism 7 and a stirring blade 8, the insertion mechanism 7 is fixed on the rotating shaft 5, and the stirring blade 8 is fixed on the insertion mechanism 7 On both sides, the insertion mechanism 7 includes a connection block 71 and an insertion block 73. A slot 72 is provided on one side of the connection block 71. The connection block 71 is fixed on one end of the rotating shaft 5, and the connection block 71 is inserted in the slot 72. The insertion block Both sides above 73 all offer limit groove 74, and slot 72 both sides walls all fix limit plate 75, and limit plate 75 is inserted in limit groove 74, and limit plate 75 is inserted in limit groove 74 The connection block 71 can be inserted into the slot 72 more stably, the rotating shaft 5 can rotate, and the insertion mechanism 7 can drive the stir...

Embodiment 3

[0027] refer to Figure 1-2 , on the basis of Embodiment 1, a filter mechanism is provided in this embodiment, and a filter mechanism is fixed on the upper side of the main casing 1. The filter mechanism includes a placement slot plate 16, and the bottom of the placement slot plate 16 and the inner wall of the main casing 1 Reinforcing ribs 23 are fixed between them, and the slot plate 16 is fixed on the upper side of the main housing 1, and a storage box 17 is placed above the slot plate 16, and a plurality of round holes 19 are provided on both sides of the storage box 17. Activated carbon 18 is placed in 17, a cover plate 21 is placed above the storage box 17, an inner panel 20 is fixed on the bottom of the cover plate 21, and the inner panel 20 is inserted in the storage box 17, and a pull ring 22 is fixed in the middle of the top of the cover plate 21. The water in the main housing 1 can enter the storage box 17 through the circular hole 19, and the water in the main hous...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com