A multi-level protection pneumatic reciprocating saw

A technology of reciprocating saw and cylinder, applied in the field of multi-level protection pneumatic reciprocating saw, can solve the problems of low safety performance, time-consuming and laborious, centrifugal motion, etc., and achieve the effect of improving safety, simple principle and improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

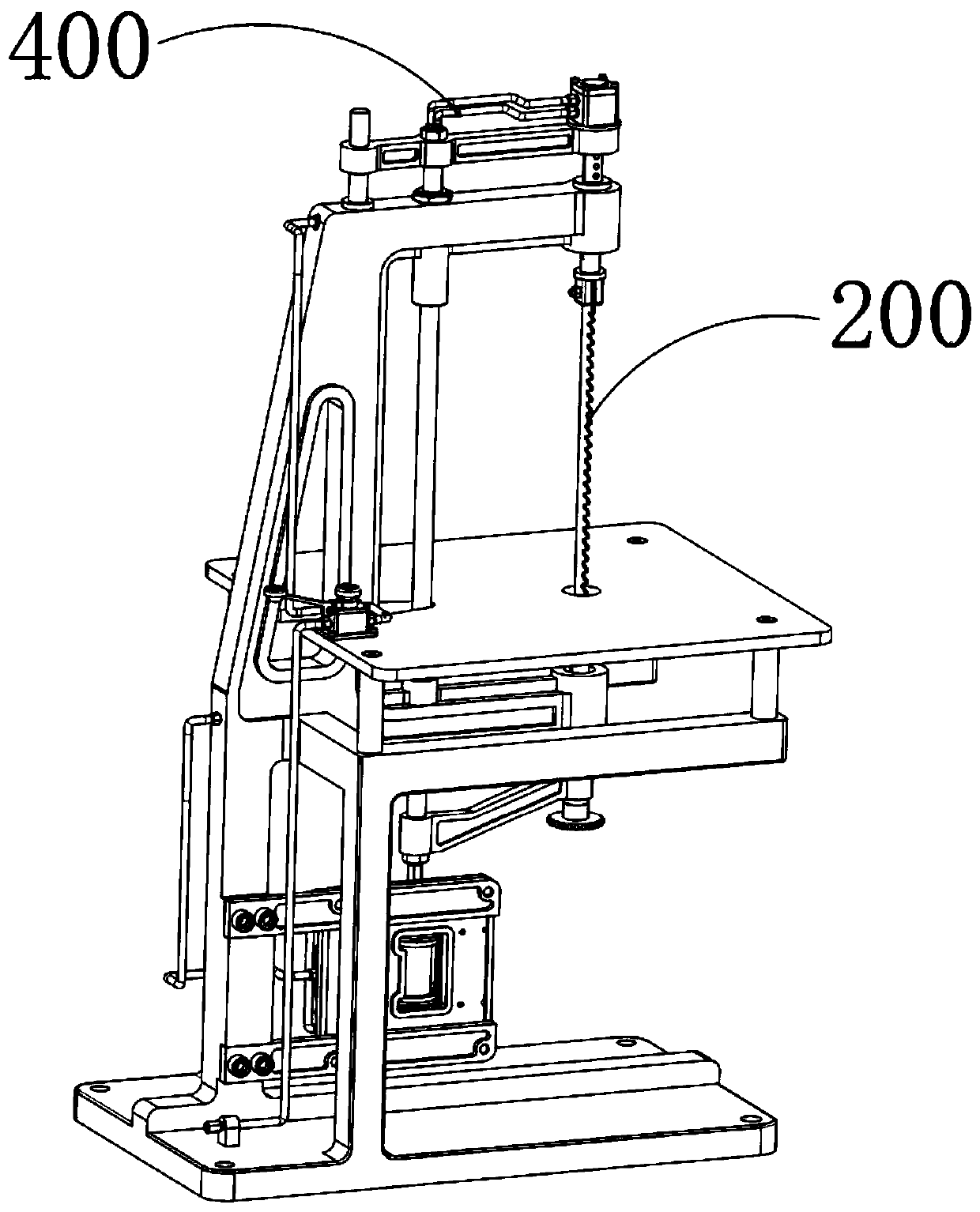

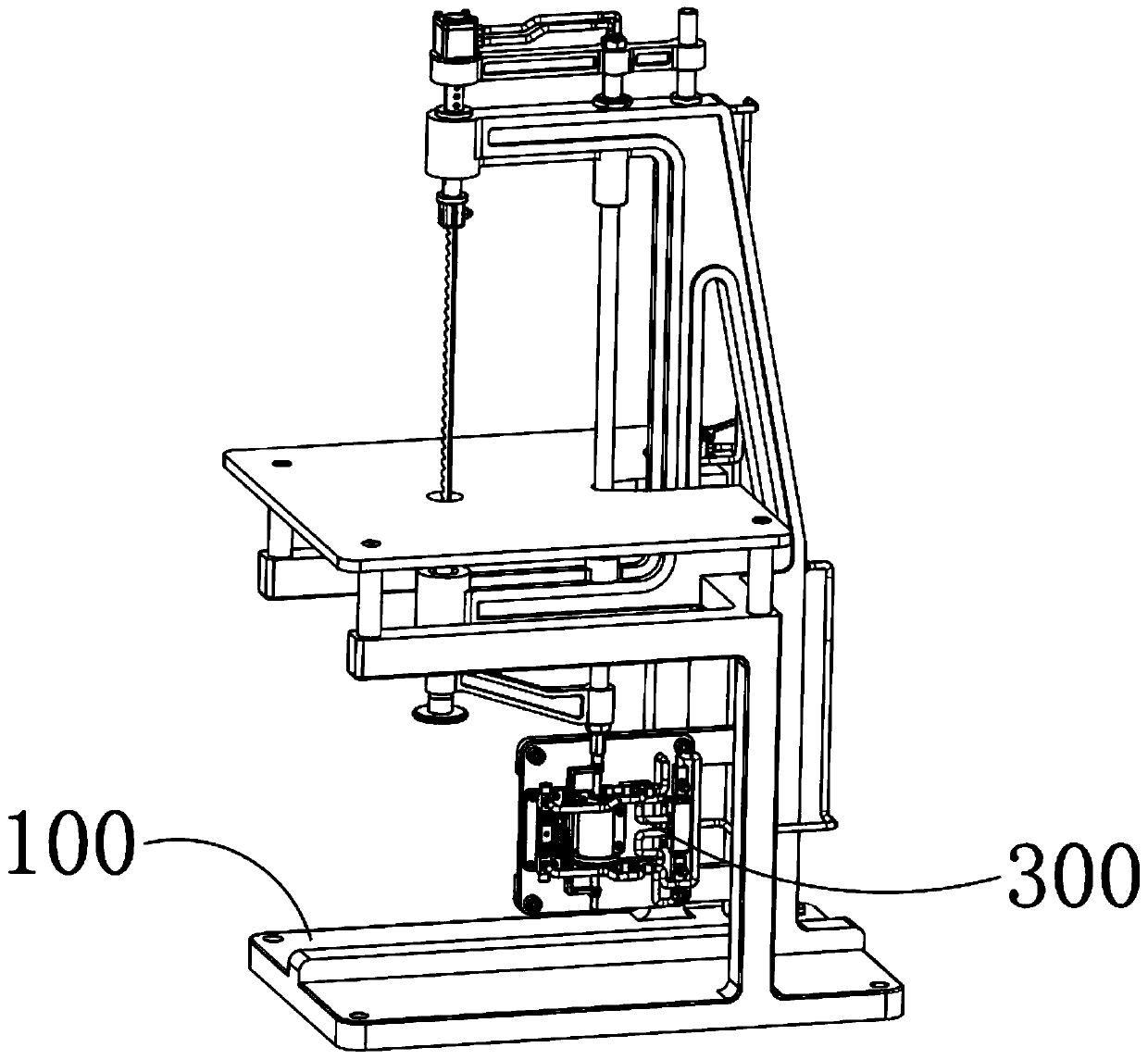

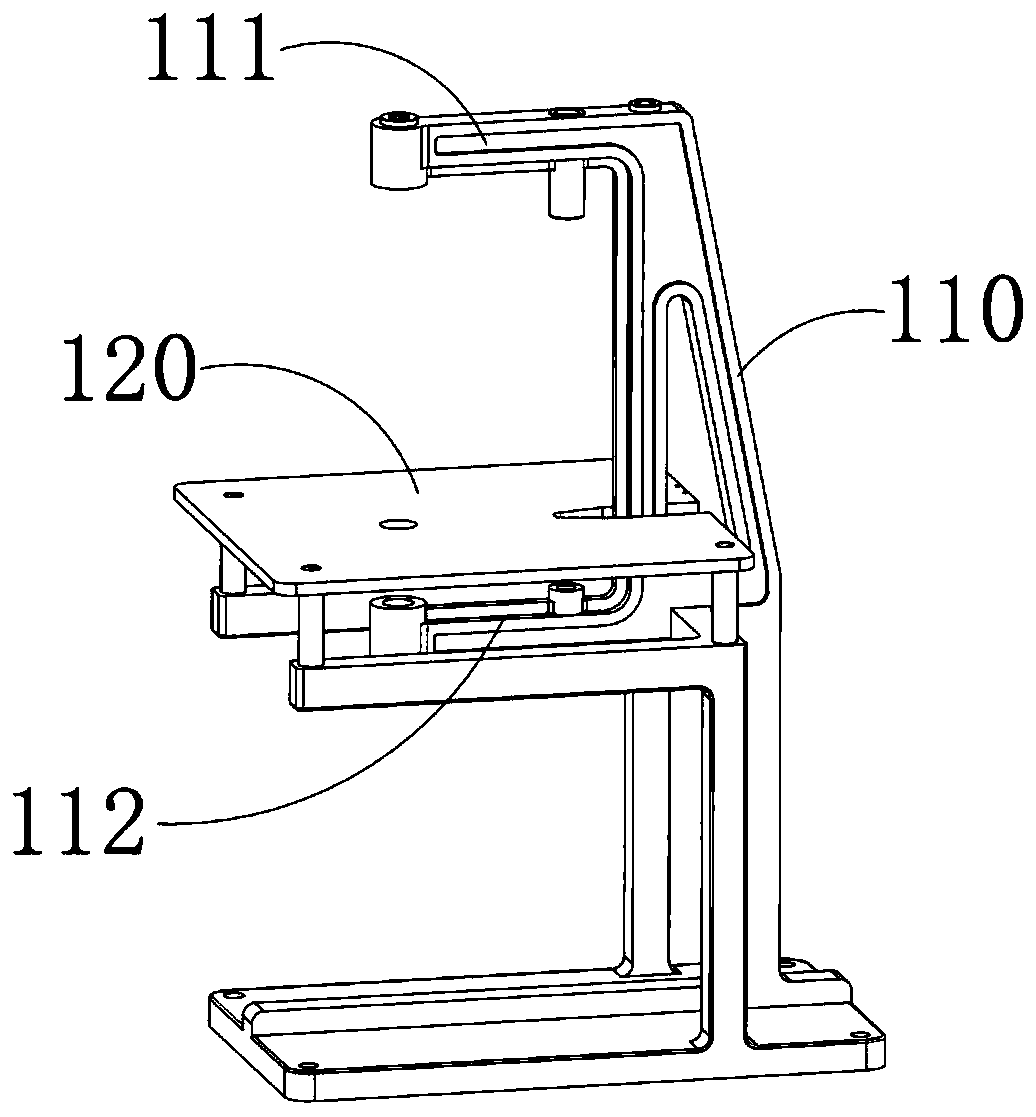

[0051] A multi-level protection pneumatic reciprocating saw, which includes a rectangular floor base 100, the top of the base 100 is provided with a support arm 110 extending vertically upwards, the top end of the support arm 110 is fixedly provided with a horizontally arranged upper arm 111, and the bottom end is fixedly provided with a The lower arm 112 arranged horizontally and the lower arm 112 is arranged correspondingly to the upper arm 111. A horizontal workbench 120 fixedly connected to the base 100 is arranged between the upper arm 111 and the lower arm 112 and the workbench 120 is arranged close to the lower arm 112. The upper arm 111 is connected to the lower arm 112. A saw body 200 is movable between the arms 112. The saw body 200 includes a saw blade 210 that is vertically arranged and moves through the workbench 120. The base 100 is provided with a pneumatic drive that drives the saw blade 210 to reciprocate up and down in the vertical direction. The device 300 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com