Soil-core wall dam preventing hydraulic fracture

A technology of hydraulic splitting and core wall dam, applied in dams, wall dams and other directions, can solve the problems of cracks in the soil anti-seepage body, affecting the operation safety of the dam, and reducing the tensile strength of the soil anti-seepage body, so as to ensure safety. Operation, avoid the effect of anti-seepage body core wall arch effect, avoid the effect of hydraulic splitting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

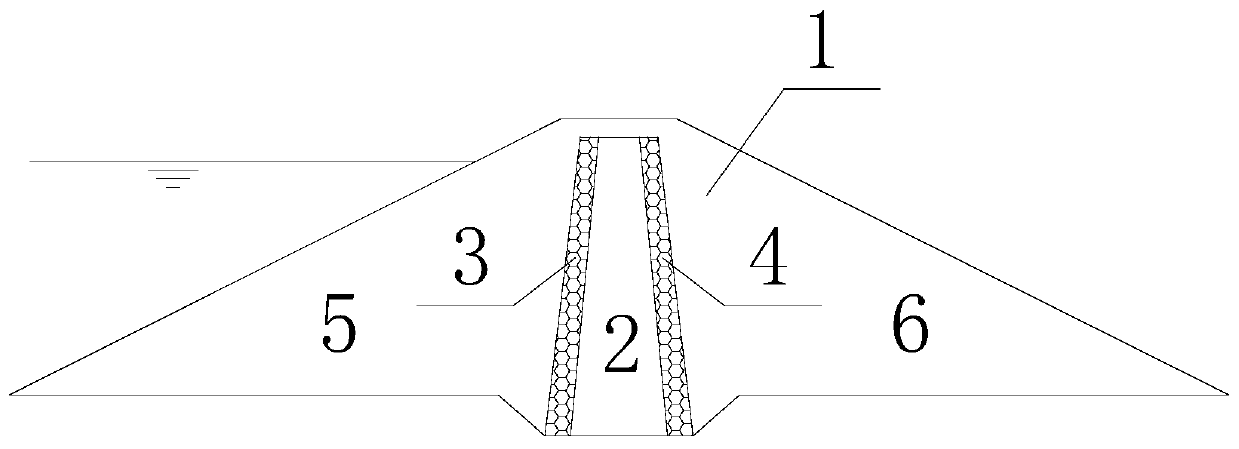

[0013] Such as figure 1 As shown, the soil core wall dam for preventing hydraulic splitting of the present invention comprises an upstream dam body, a core wall, and a downstream dam body, and the upper and lower sides of the core wall 2 provided by the soil core wall dam 1 are respectively staggered and stacked with upstream soil bag 3 and downstream soil bag 4, the upstream dam shell material 5 and the downstream dam shell material 6 are filled outside the upstream soil bag 3 and the downstream soil bag 4.

[0014] Preferably, the core wall 2 is a clay core wall.

[0015] The bag material of the upstream soil bag 3 and the downstream soil bag 4 is a water-permeable geosynthetic material. The earth material contained in the upstream earth bag 3 and the downstream earth bag 4 is the same as that of the core wall 2, the stacking width is betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com