Automatic feeder for poultry farming

A poultry and automatic technology, applied in the field of poultry breeding, can solve the problems of poultry digestive system infection, difficult to recycle feed, waste of feed, etc., and achieve the effects of avoiding excessive feeding, low cost and simple principle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

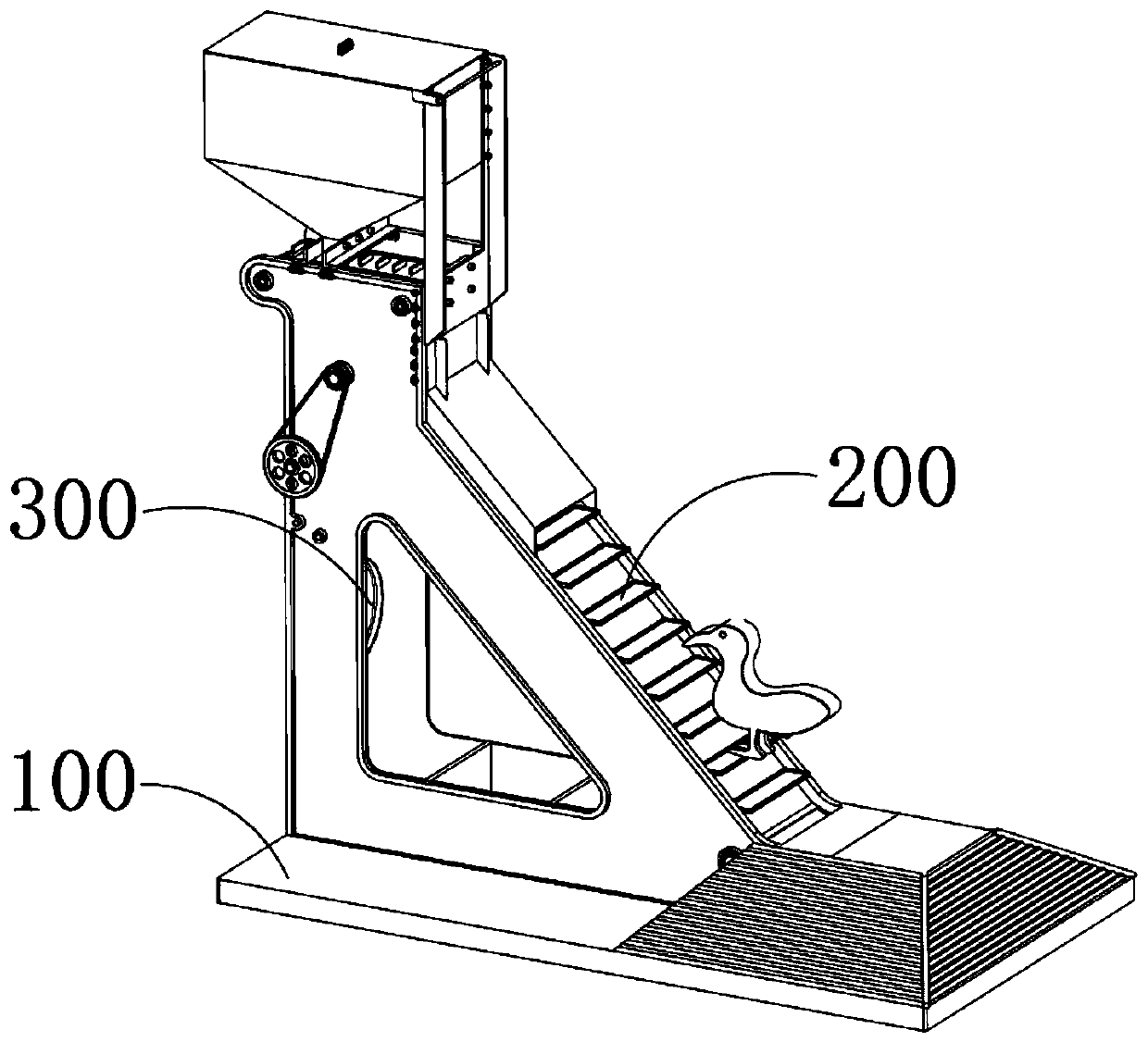

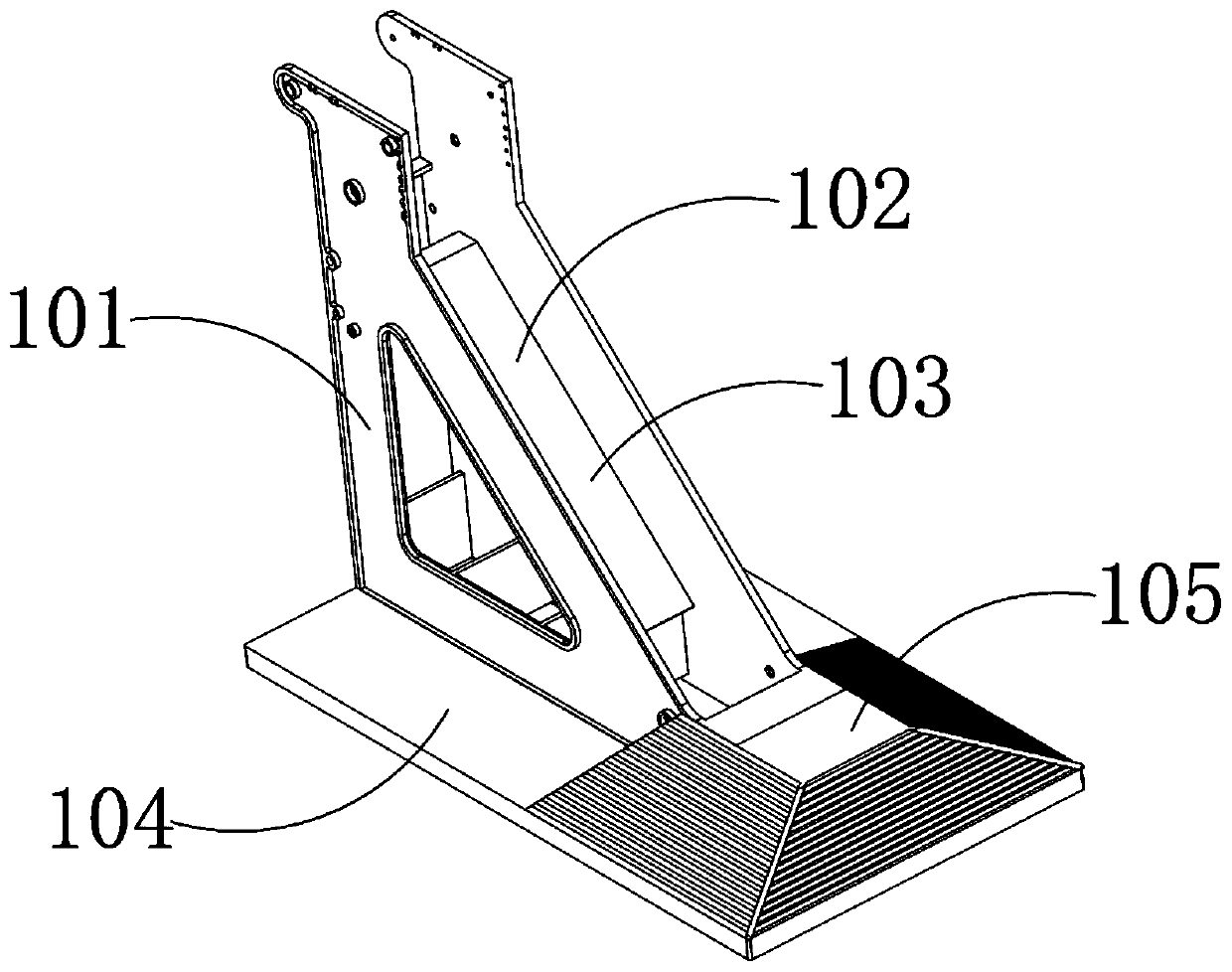

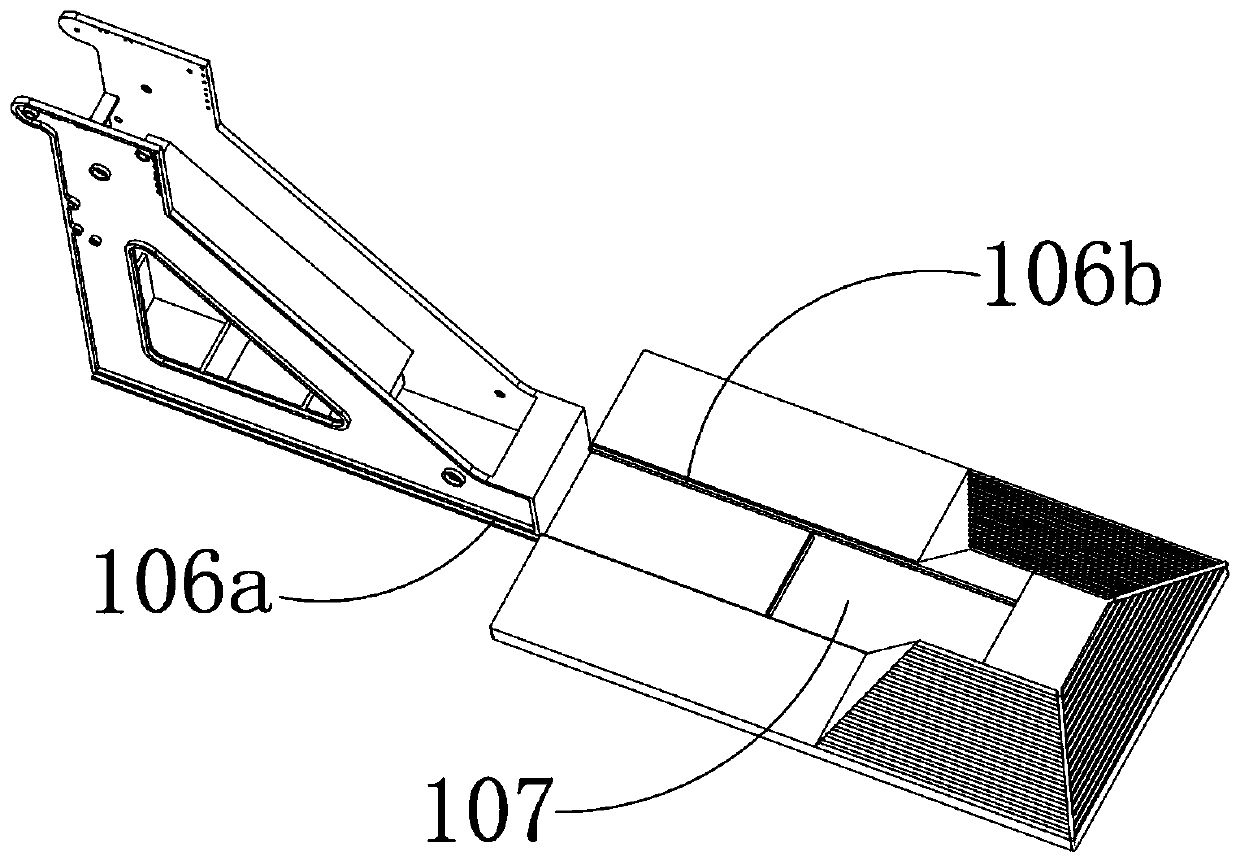

[0039] An automatic feeding machine for poultry breeding, which includes a mounting frame 100, an automatic feeding device 200, and a warning and driving away component 300. Both the automatic feeding device 200 and the warning and driving away component 300 are installed on the mounting frame 100. The automatic feeding device 200 is used to automatically release feed and supply poultry to eat, and the warning and driving away component 300 is used to drive away poultry. The mounting frame 100 includes a vertical plate 101 arranged in a right triangle, and the vertical surface of the vertical plate 101 is horizontal Arranged on the ground, two vertical plates 101 are provided and are arranged parallel to each other. An inclined connecting plate 102 for fixed connection between the two vertical plates 101 is provided and the connecting plate 102 is parallel to the slope of the vertical plate 101. The connecting plate 102 An installation area 103 is formed on the top, and an inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com