Single-channel multi-level hydraulic power generation technology

A technology of water conservancy and technology, applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve the problems of low utilization rate of water energy, achieve full utilization and attenuation, reduce impact force, and shorten the length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

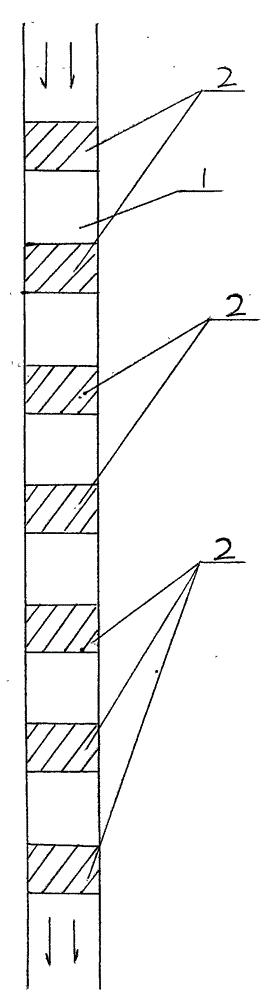

[0020] exist figure 1In the shown embodiment, a plurality of water turbines (2) are sequentially installed on the water diversion channels (1) with equal upstream and downstream cross-sectional areas, and the water turbines (2) at the front and rear stages are arranged in series, and each stage of water turbines is connected to the generator set through a rotating shaft.

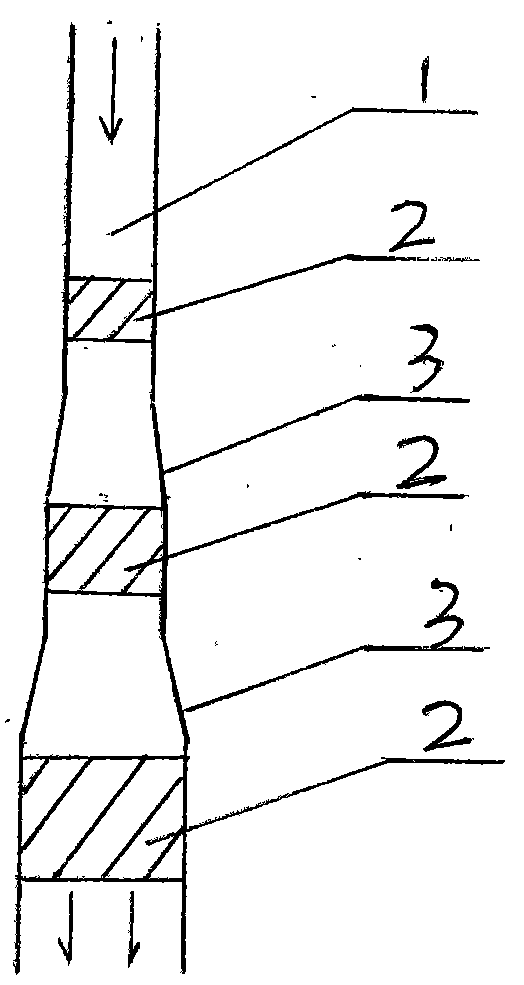

[0021] exist figure 2 In another embodiment shown, a plurality of water turbines (2) are installed sequentially on the water diversion channel (1), the water turbines (2) at the front and rear levels are arranged in series, and the downstream water turbines are installed at the front end of the corresponding water diversion channel (1) , and the cross-sectional area of the water diversion channel corresponding to the next stage turbine is equal to the cross-sectional area of the water diversion channel corresponding to the upper stage turbine times, the transitional section between the water diversion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com